Pipeline inner wall clearing device used for pipeline repairing through insertion method

A pipeline repair and cleaning device technology, which is applied in the direction of cleaning methods and tools, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of labor consumption of staff, limited area, and inability to guarantee the cleaning efficiency of the inner wall of the pipeline, etc., to achieve The effect of high adaptability, less mess, and less waste water collection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present application will be further described in detail below with reference to all the accompanying drawings.

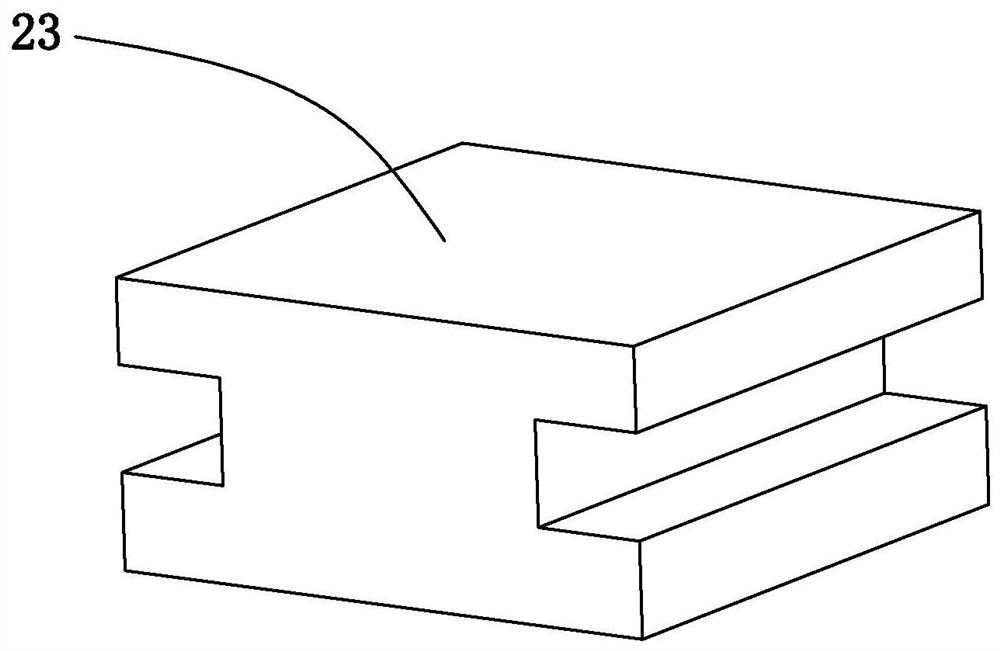

[0042] A pipeline inner wall cleaning device used for interpenetrating pipeline repair, such as figure 1 As shown, it includes a cylindrical shell 1, a cavity is opened inside the shell 1, one end of the shell 1 is provided with an opening, and the shell 1 is located on one side of the opening and is bolted with a cover to cover the end of the shell 1 12. The outer peripheral surface of the casing 1 is also provided with two distance adjusting mechanisms 2 for supporting the casing 1 in the middle of the pipeline. A spray cleaning mechanism 4 and a descaling mechanism 3 are arranged between the two distance adjusting mechanisms 2 for cleaning the inner wall of the pipeline, and a recovery device 7 for recovering most of the cleaned waste water is also arranged beside the spray cleaning mechanism 4 .

[0043] like figure 1 and figure 2 As shown, two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com