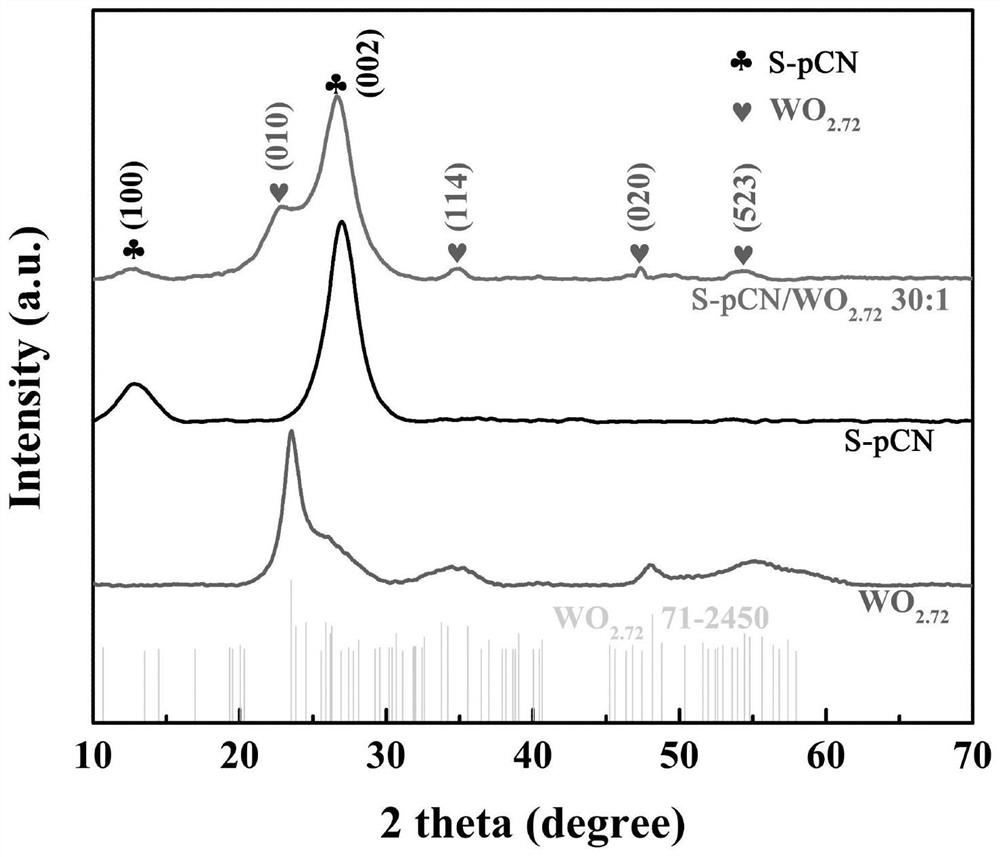

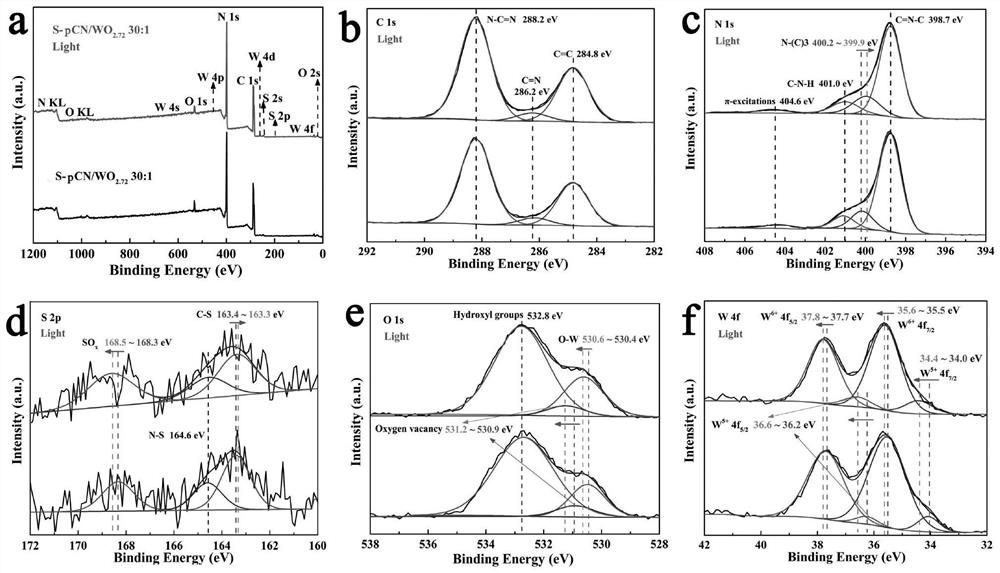

Preparation method of two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride/defective tungsten oxide

A heterojunction and recombination light technology, which is applied in the field of environmental pollution control, can solve the problems that the legacy pollution is difficult to be solved reasonably, and there is no composite construction of S-type heterojunction photocatalysts, etc., so as to improve the redox ability and high sunlight Effect of Utilization, Accelerated Transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride / defective tungsten oxide, comprising the following steps:

[0025] (1) In a typical synthesis, 10g of urea was added to 20mL of distilled water, stirred magnetically at 25°C for 30min until it was dissolved, then added 10mg of thioacetamide, stirred at 25°C for 1h to obtain a colorless transparent solution, transferred Put it into a crucible in a semi-closed state, raise the temperature to 300°C at a heating rate of 5°C / min in a rapid heating furnace, and keep it for 1 hour; to room temperature, grind and sieve to obtain S-pCN;

[0026] (2) Weigh 1g of tungsten chloride and add it to a conical flask containing 80mL of ethanol, fill it with N for 5min 2 After compressing the gas and sealing it, stir rapidly for 5 minutes under completely sealed conditions to completely dissolve it into a yellow liquid, quickly transfer it to a 100ml polytetrafluoroet...

Embodiment 2

[0029] A method for preparing a two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride / defective tungsten oxide, comprising the following steps:

[0030] (1) In a typical synthesis, add 30g of urea into 40mL of distilled water, stir magnetically at 60°C for 30min until it dissolves, add 100mg of thioacetamide, stir at 60°C for 1h to obtain a colorless transparent solution, and then Transfer it into a semi-closed crucible, raise the temperature to 350°C at a heating rate of 20°C / min in a rapid heating furnace, and keep it for 4 hours; Cool down to room temperature, grind and sieve to get S-pCN;

[0031] (2) Weigh 3g of tungsten chloride and add it to a conical flask containing 200mL of ethanol, fill it with N for 5min 2 After compressing the gas and sealing it, stir rapidly for 5 minutes under completely sealed conditions to completely dissolve it into a yellow liquid, quickly transfer it to a 300ml polytetrafluoroethylene liner, and f...

Embodiment 3

[0034] A method for preparing a two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride / defective tungsten oxide, comprising the following steps:

[0035] (1) In a typical synthesis, 50g of urea was added to 80mL of distilled water, stirred magnetically at 80°C for 30min until it was dissolved, then added 200mg of thioacetamide, stirred at 80°C for 1h to obtain a colorless transparent solution, and transferred to In a crucible in a semi-closed state, heat up to 400°C at a heating rate of 30°C / min in a rapid heating furnace, and hold for 8 hours; then raise the temperature to 600°C at a heating rate of 30°C / min, hold for 8 hours, and then cool down naturally. to room temperature, grind and sieve to obtain S-pCN;

[0036] (2) Weigh 5g of tungsten chloride and add it to a conical flask containing 400mL of ethanol, fill it with N for 5min 2 After compressing the gas and sealing it, stir it quickly for 15 minutes under completely sealed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com