In-vitro cultivated calculus bovis and preparation method thereof

A technology for cultivating bezoar and ox bile in vitro, applied in the field of in vitro cultivating bezoar, can solve problems such as many control links, differences in bile acid content, and insufficient utilization of ox bile resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

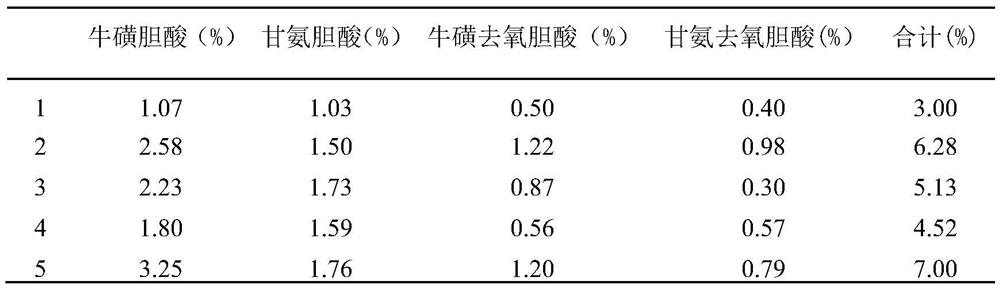

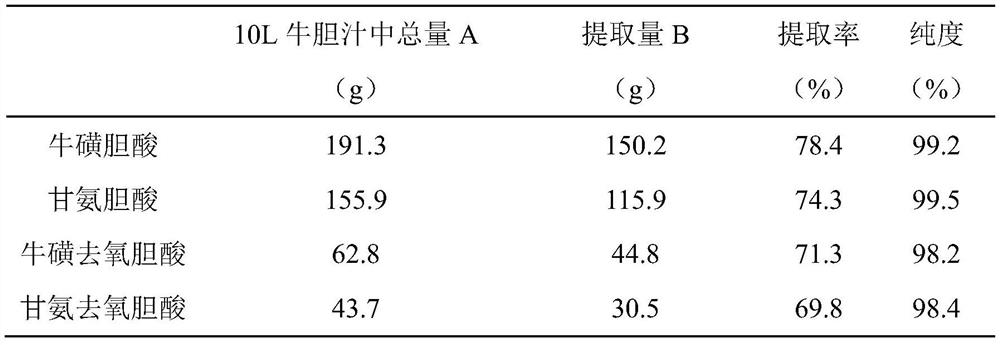

[0027] [Example 1] Carry out implementation according to the new process of cultivating Calculus Bovis in vitro of the present invention

[0028]Using 10L of ox bile as raw material, add 1L of 0.02% CTAB solution, stir for 5min, let stand for 30min, filter to remove the precipitate, and obtain 10.95L of filtrate, adjust the pH of the filtrate to 10.3 with sodium hydroxide, add 250ml of 0.02% zinc sulfate solution and 250ml. .01% calcium chloride solution to form a metal salt complex, filter to obtain the filtrate, adjust the pH to 1.5 with concentrated hydrochloric acid, stir for 2 minutes, let stand for 20 minutes, centrifuge to collect 500g of precipitate, take 500g of precipitate and 400g of silica gel (100 mesh) Directly mix the sample and dry to obtain the mixed sample silica gel, with a height of 5 cm, an inner diameter of the silica gel chromatography column of 22 cm, a column packing silica gel (100 mesh) amount of 5 kg, and a height of 35 cm. Elute with ethyl acetate / ...

Embodiment 2

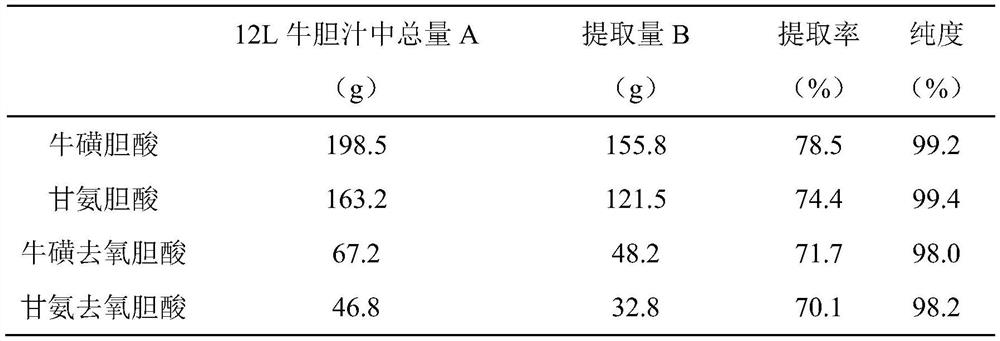

[0033] [Embodiment 2] Carry out implementation according to the new process of cultivating Calculus Bovis in vitro of the present invention

[0034] Using 12L of ox bile as raw material, add 1.2L of 0.02% CTAB solution, stir for 5min, let stand for 30min, filter to remove the precipitate, and obtain 13.15L of filtrate, adjust the pH of the filtrate to 10.3 with sodium hydroxide, add 260ml of 0.02% zinc sulfate solution and 260ml 0.01% calcium chloride solution to form a metal salt complex, filter the filtrate, adjust the pH to 1 with concentrated hydrochloric acid, stir for 2min, let stand for 20min, centrifuge to collect 570g of precipitate, take 570g of precipitate and 400g of silica gel (200 mesh) Directly mix the sample and dry to obtain the mixed sample silica gel, with a height of 5.8 cm, an inner diameter of the silica gel chromatography column of 22 cm, a column packing silica gel (200 mesh) amount of 5 kg, and a height of 35 cm. Elute with ethyl acetate / methanol / formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com