Feeding equipment used in zizania latifolia stalk cutting machine

A technology of water bamboo straw and feeding equipment, which is applied in cutting equipment, application, agricultural machinery and implements, etc., can solve the problems that the pressing force of feeding equipment cannot be adjusted and cannot meet the work requirements, etc., and achieves wide adjustment range and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

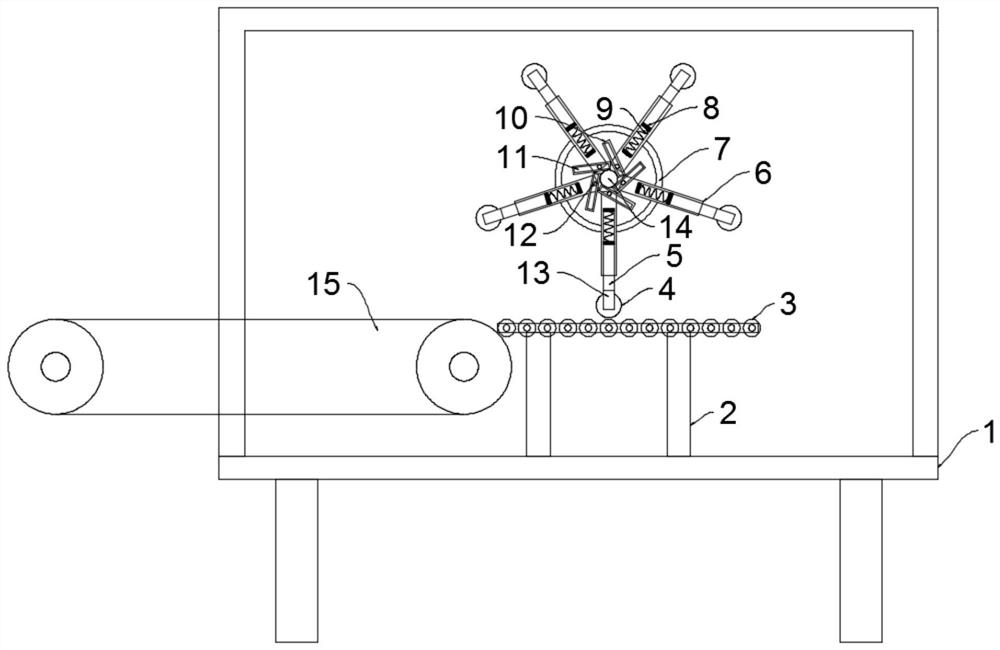

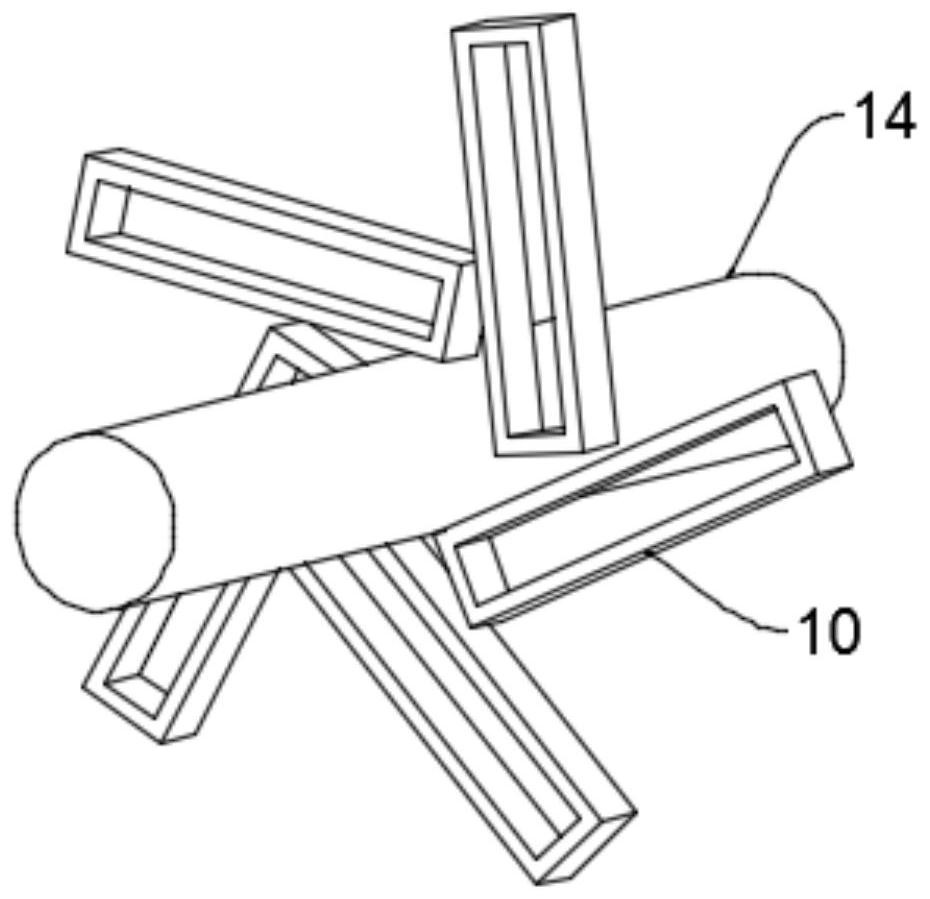

[0024] see Figure 1~2 , in the embodiment of the present invention, a kind of feeding equipment used in the rice stem straw guillotine cutter comprises a frame 1, a workbench 2 and a feed unit, the workbench 2 is fixedly installed on the frame 1, and the frame 1 is installed with a conveyor belt 15 for transporting straw to the workbench 2, and a plurality of conveying rollers 3 are installed on the upper surface of the workbench 2 to rotate at intervals. The feeding unit includes a hollow installation column 7, a sleeve 6, and a installation rod. 5. Adjust the shaft 14 and the driving rod 10. The hollow mounting column 7 is rotatably mounted on the frame 1 and is located above the workbench 2. The driving member for driving the hollow mounting column 7 to rotate is also installed on the frame 1. In this implementation In an example, the driving member is preferably a geared motor, and the output shaft of the geared motor is fixedly connected to the hollow mounting column 7 t...

Embodiment 2

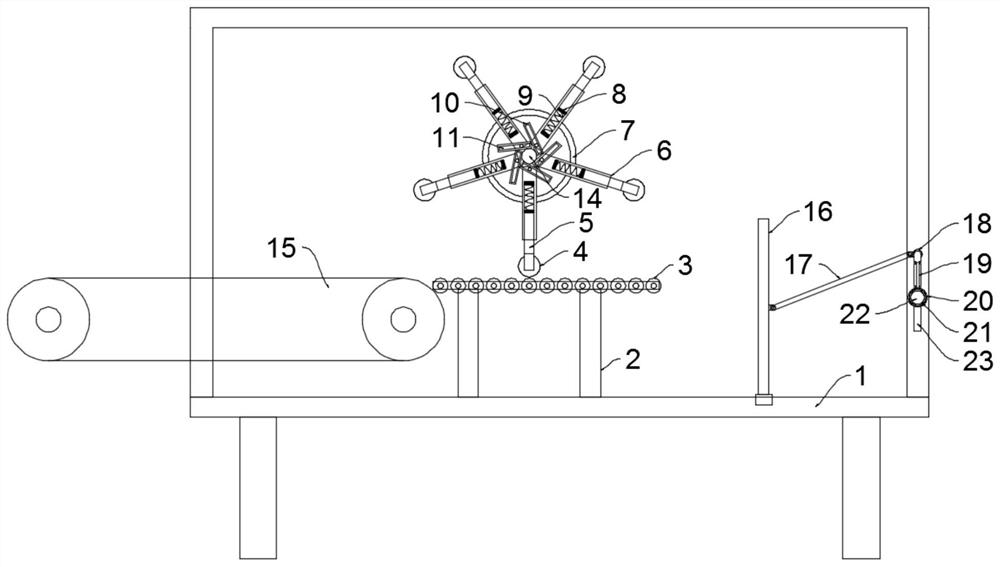

[0027] see Figure 3-4The difference between this embodiment of the present invention and Embodiment 1 is that, in order to be able to adjust the length of straw cutting, an adjustment unit is installed on the frame 1 on the side of the workbench 2 away from the conveyor belt 15, and the adjustment unit includes a crankshaft 22 , the first sleeve 21, the second sleeve 20, the first connecting rod 19, the adjusting rod 23 and the third sleeve 18, the crankshaft 22 is rotationally connected with the frame 1 and the locking bolts for positioning are connected between the two , both ends of the connecting rod journal of the crankshaft 22 are fixed with adjusting rods 23, the adjusting rods 23 move through the crankshaft 22, the shaft sections on both sides of the crankshaft 22 are provided with external threads, and the external thread sections on both sides of the crankshaft 22 The first sleeve 21 is set in the uniform thread, and the second sleeve 20 is installed in rotation on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com