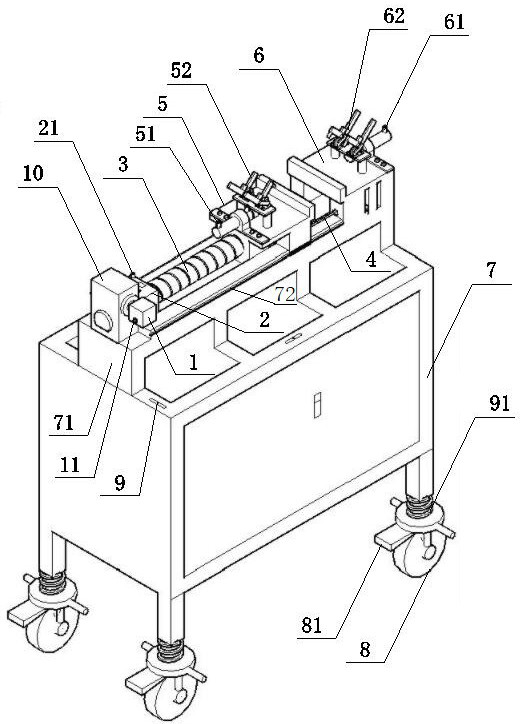

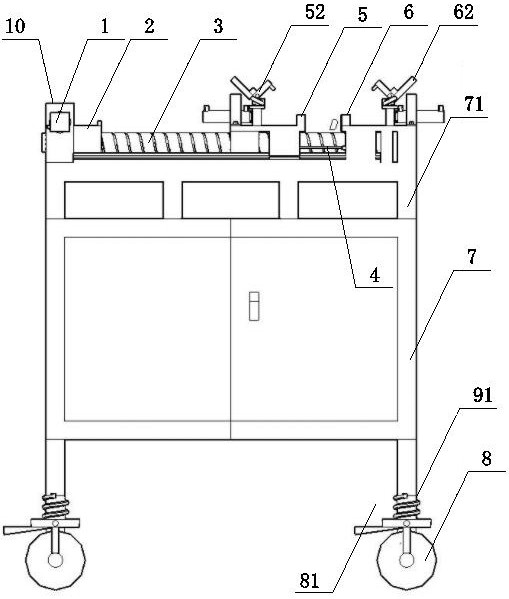

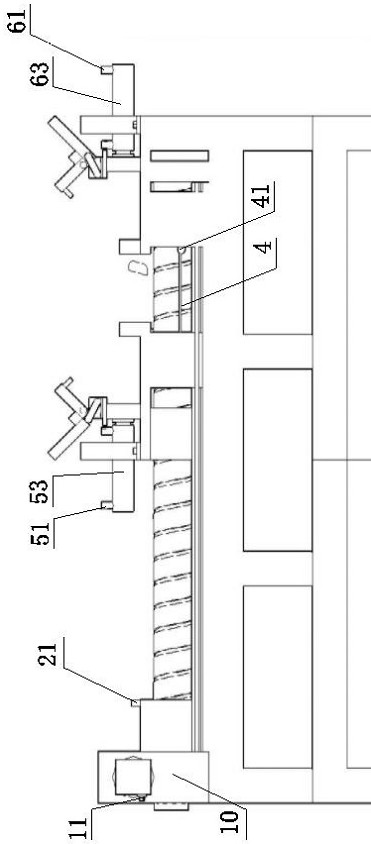

Test equipment for MA modular bridge expansion device and test method thereof

A technology of expansion devices and test equipment, which is applied in bridge construction, bridges, bridge parts, etc., can solve the problems of lack of detection equipment and detection methods for MA modular bridge expansion devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] A test method for the test equipment of the MA modular bridge expansion device--the test method for the qualified judgment of the section size, the qualified judgment of the designed expansion and contraction, and the qualified judgment of the clamping performance of the rubber sealing tape:

[0114] Step 1. Judgment of the qualified cross-sectional size of the sample:

[0115] Place the MA modular bridge expansion device (hereinafter referred to as the sample) in the test room at 23°C ± 5°C for no less than 24 hours. There should be no corrosive gas and vibration sources that affect the detection in the test room.

[0116] Move the two sets of equipment of the present invention to the designated test position through the moving wheel 8 and fix the equipment of the present invention by means of the limiter 81, and use the cooperation of the level gauge 9 and the leveling device 91 to level the equipment of the present invention.

[0117] By adjusting the position of the...

Embodiment 2

[0165] A test method for the test equipment of the MA modular bridge expansion device-vertical misalignment test method:

[0166] The difference between this embodiment and embodiment 1 lies in the following content:

[0167] In this test, the height of the sample side beam fixed at the front end of the test device of the present invention is kept constant, and the test is carried out by adjusting the height of the sample side beam pad of the test device at the rear end, simulating the situation that the vertical dislocation of the bridge in the expansion joint occurs in reality .

[0168] When step 2 test is qualified in embodiment 1, change over to following test procedure:

[0169] Step B: Vertical misalignment test:

[0170] The test conditions are the same as in Example 1.

[0171] 1. The sample is fixed.

[0172] Before the sample is fixed in step 2, the edge beam of the front-end sample is raised with pads, specifically: the pads whose length and width correspond to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com