Compound silencing device for air suction of high speed centrifugal fan

A technology of muffler and high-speed centrifugation, which is applied to the components of pumping devices for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc. and other problems, to achieve the effect of anechoic frequency bandwidth, simple manufacturing process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

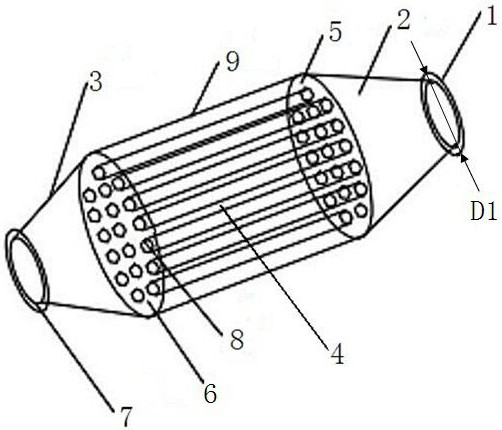

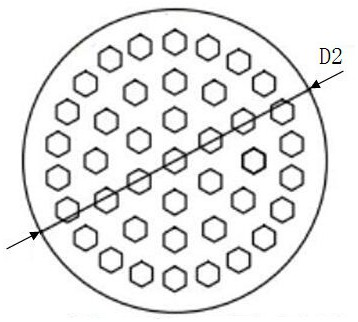

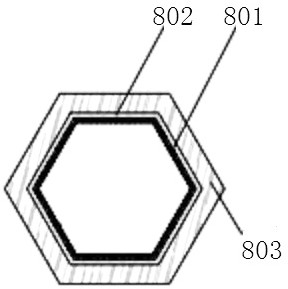

[0023] like figure 1 Shown is a composite muffler for the air intake of a high-speed centrifugal fan provided by the present invention, including an inlet flange 1, a first expander 2, a second expander 3, a muffler 4, an upper end cover 5, The lower end cover 6 and the outlet flange 7; the small end of the first expander 2 is connected to the inlet flange 1, and the large end is connected to the upper end cover 5; the muffler device is fixed between the upper end cover 5 and the lower end cover 6; as figure 2 As shown, the muffler device includes a housing 9 and a muffler channel 8, the muffler channels 8 are arranged side by side in the housing 9, and the cross-sectional shape of the muffler channel 8 is a regular hexagon.

[0024] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com