Low-speed diesel engine electronically controlled high-pressure oil pump

A high-pressure oil pump and diesel engine technology, applied in electrical control, engine control, pumps, etc., can solve the problems of inaccurate injection control, slow response speed, insufficient injection pressure, etc., and achieve good fuel atomization and large injection volume , The effect of reducing carbon smoke emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

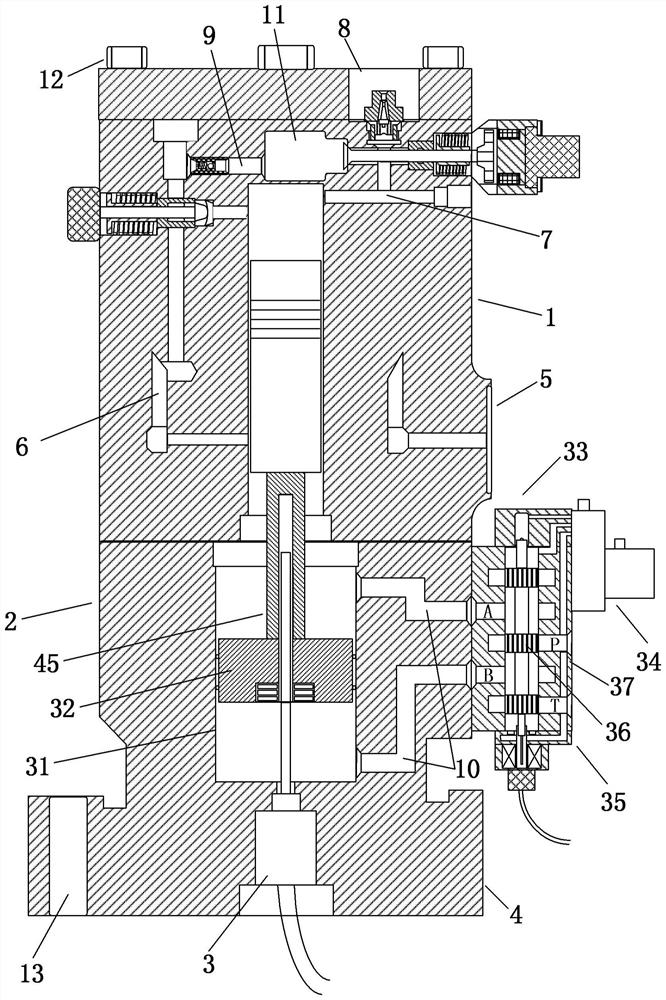

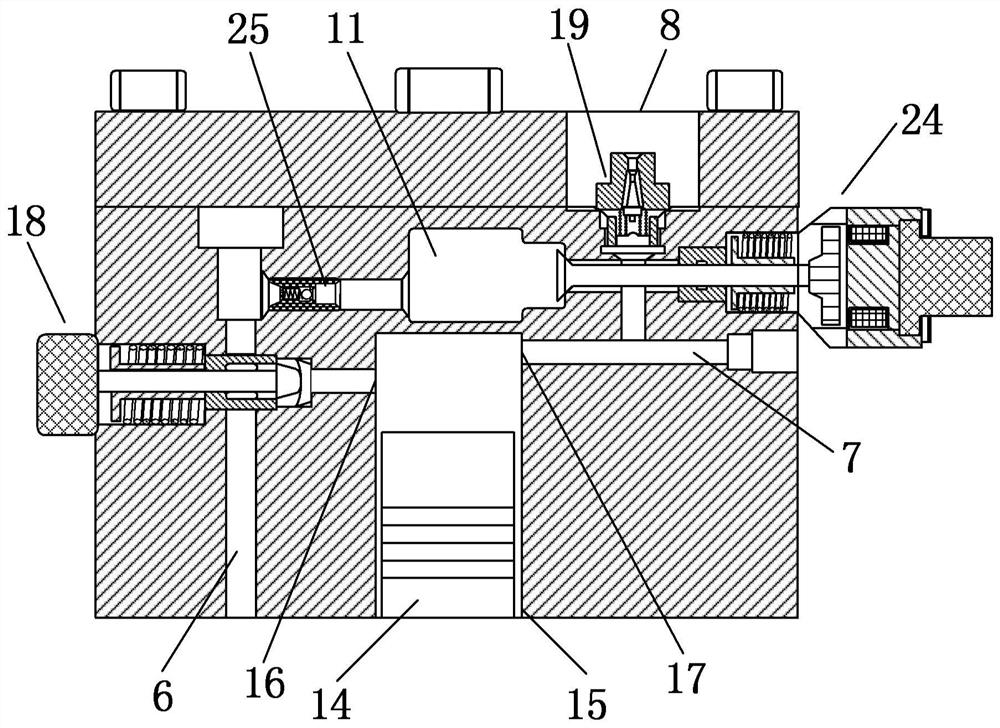

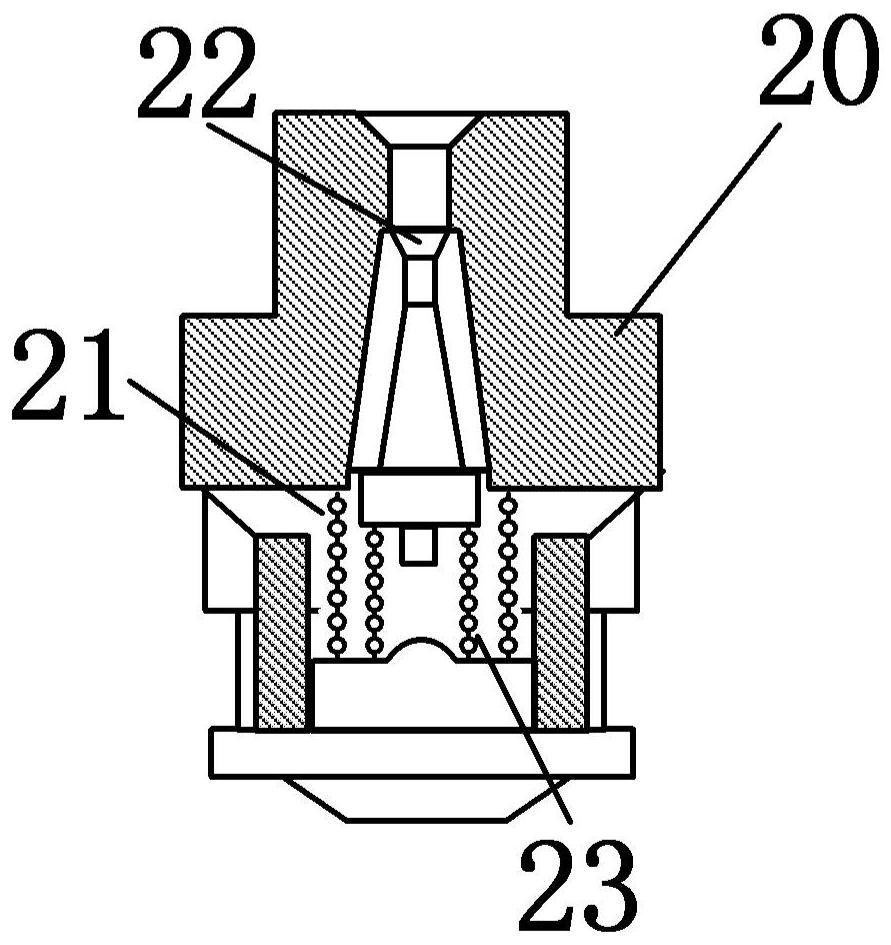

[0030] The disclosure provides an electronically controlled high-pressure oil pump for a low-speed diesel engine, which realizes electronic control of the high-pressure oil pump and multiple injections of diesel, namely, pre-injection, main injection and post-injection. The hydraulic drive unit drives the plunger to make the high-pressure oil pump of the diesel engine Injection control is more precise, fuel combustion quality and emissions are greatly improved.

[0031] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0032] In an embodiment of the present disclosure, an electronically controlled high-pressure oil pump for a low-speed diesel engine is provided, combined with Figure 1 to Figure 5 As shown, the low-speed diesel engine electronically controlled high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com