Fruit grading treatment equipment

A technology for processing equipment and fruit grading, which is applied in food processing, solid separation, filtering and sieving, etc. It can solve the problems of low screening efficiency and low sieving rate, and achieve high screening efficiency and sieving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

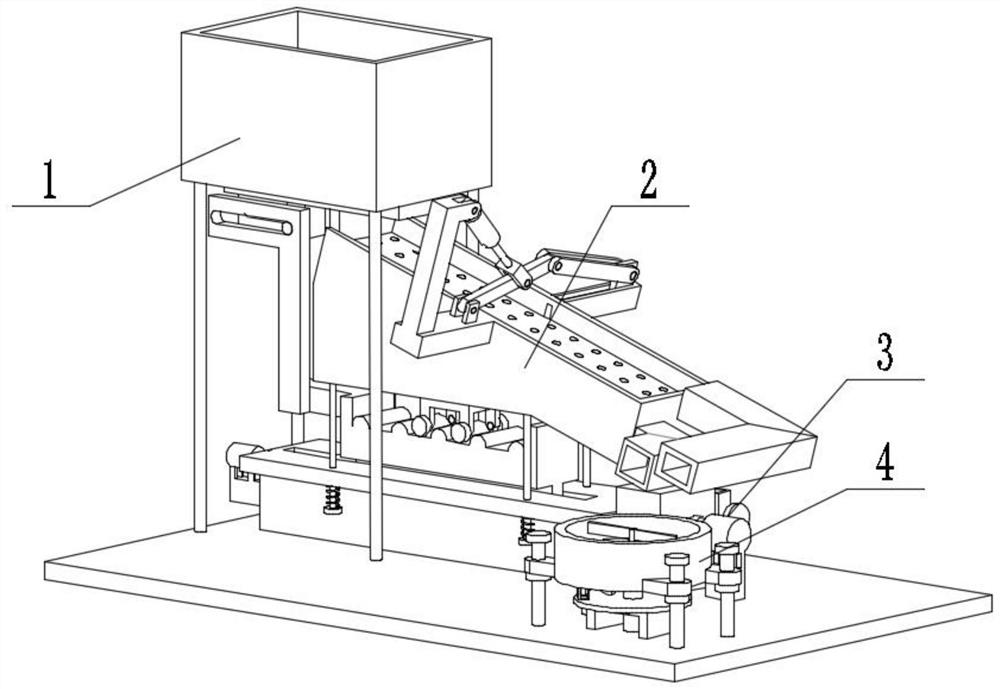

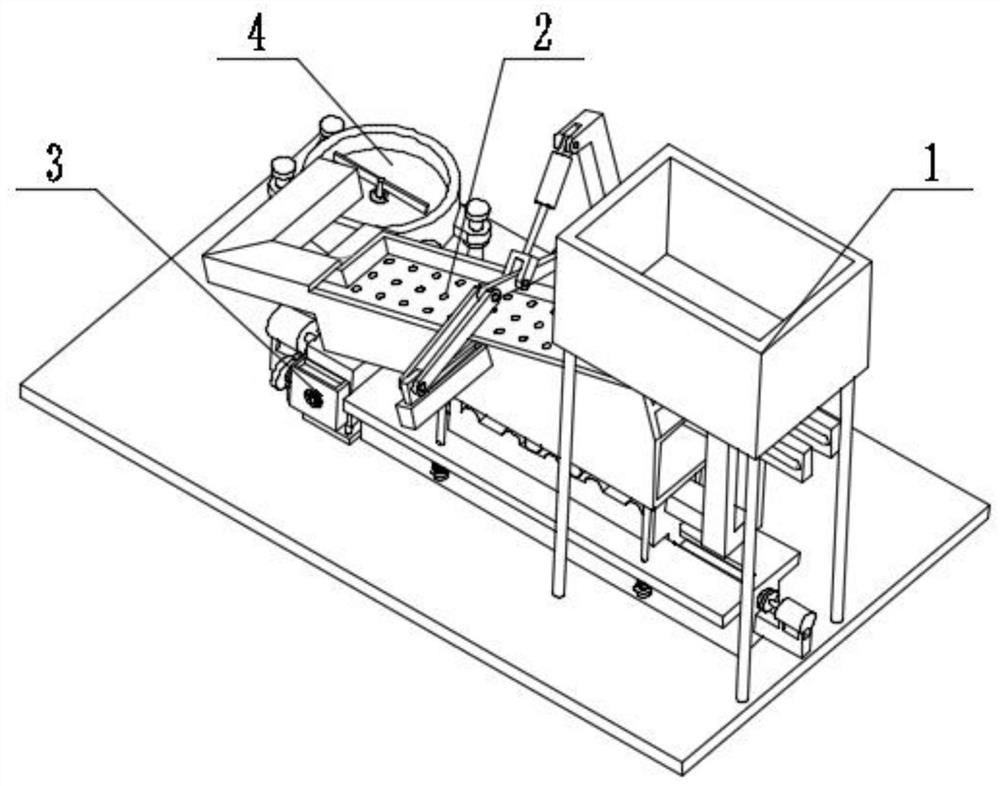

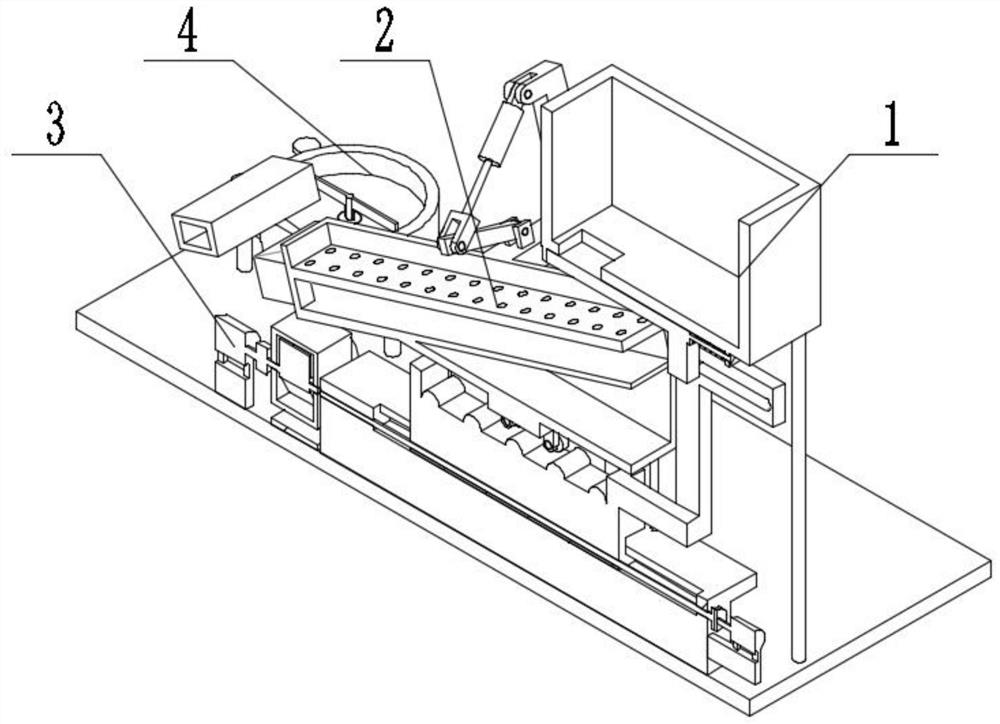

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 To illustrate this embodiment, the present invention relates to a grading equipment, more specifically a fruit grading processing equipment, including a feed box mechanism 1, a screening mechanism 2, a dust removal mechanism 3, and a cleaning mechanism 4, and the equipment can intermittently discharge , the equipment can be screened, the equipment can perform high screening efficiency and screening rate, and the equipment can clean the fruit.

[0033] The feed box mechanism 1 is connected with the screening mechanism 2 , the feed box mechanism 1 is connected with the dust removal mechanism 3 , and the feed box mechanism 1 is connected with the cleaning mechanism 4 .

specific Embodiment approach 2

[0035] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 This embodiment will be described. This embodiment will further explain the first embodiment. The feed box mechanism 1 includes a base 1-1, a leg 1-2, a boss 1-3, a limit head 1-4, Material box body 1-5, inlet 1-6, raised seat 1-7, sliding door 1-8, ladder rod 1-9, spring 1-10, matching hole 1-11, door slide rail 1-12 , box leg 1-13, outlet 1-14, base 1-1 is connected with leg 1-2, leg 1-2 is provided with boss 1-3, limit head 1-4, feed The box body 1-5 is provided with an entrance 1-6, and the raised seat 1-7 is connected with the sliding door 1-8, and the sliding door 1-8 is connected with the ladder rod 1-9, and the spring 1-10 is set on the ladder rod 1-9, the spring 1-10 is against the sliding door 1-8 and the door panel slide rail 1-12, the doo...

specific Embodiment approach 3

[0037] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 Describe this embodiment, this embodiment will further explain the first embodiment, the screening mechanism 2 includes a base 2-1, a bearing seat 2-2, a large material outlet 2-3, a small material outlet 2-4, a sieve box 2-5, screen plate 2-6, hinged support 2-7, hydraulic cylinder 2-8, piston rod with hinged joint 2-9, hinged arm 2-10, hinged arm A2-11, ladder slider 2-12 , push arm 2-13, waist groove 2-14, ladder groove 2-15, moving seat with ladder block 2-16, servo motor 2-17, ladder leg 2-18, light hole 2-19, spring A2- 20. Semicircle protrusion 2-21, pulley 2-22, pulley seat 2-23, ladder chute I2-24, retaining plate 2-25, coupling 2-26, lead screw 2-27, threaded hole 2 -28, blind plate 2-29, the base 2-1 is connected with the base 1-1, the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com