Auxiliary tooling for glue spraying of stabilizer bar bushing

A technology of stabilizer bushing and auxiliary tooling, which is applied in the direction of spraying devices, etc., can solve problems such as uneven glue spraying, and achieve the effect of uniform glue spraying and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

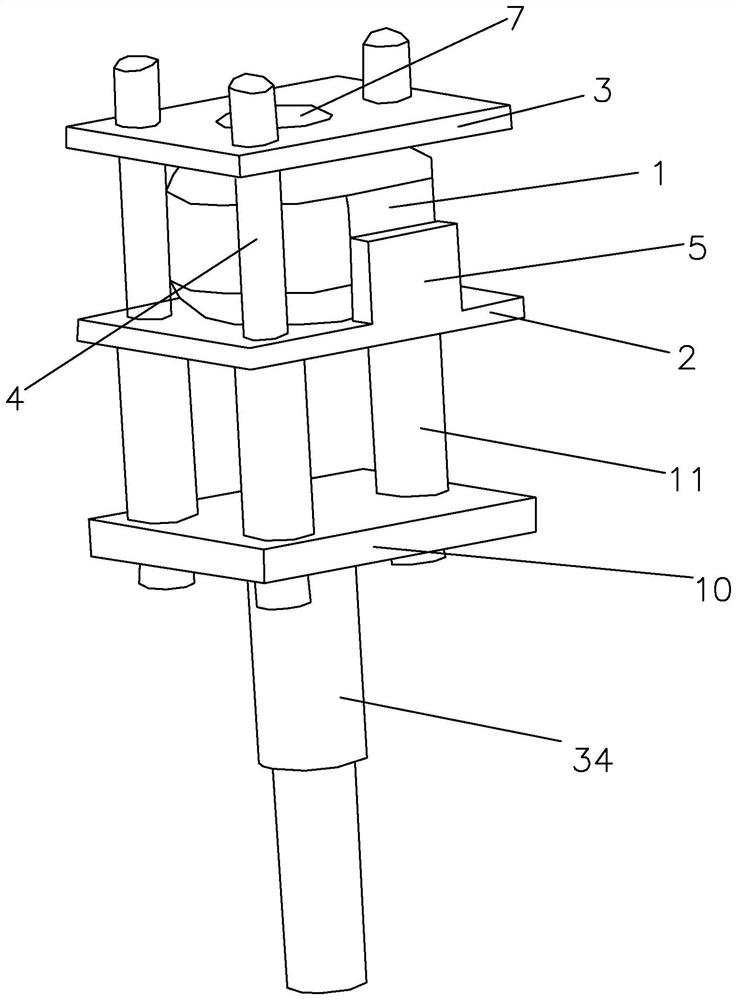

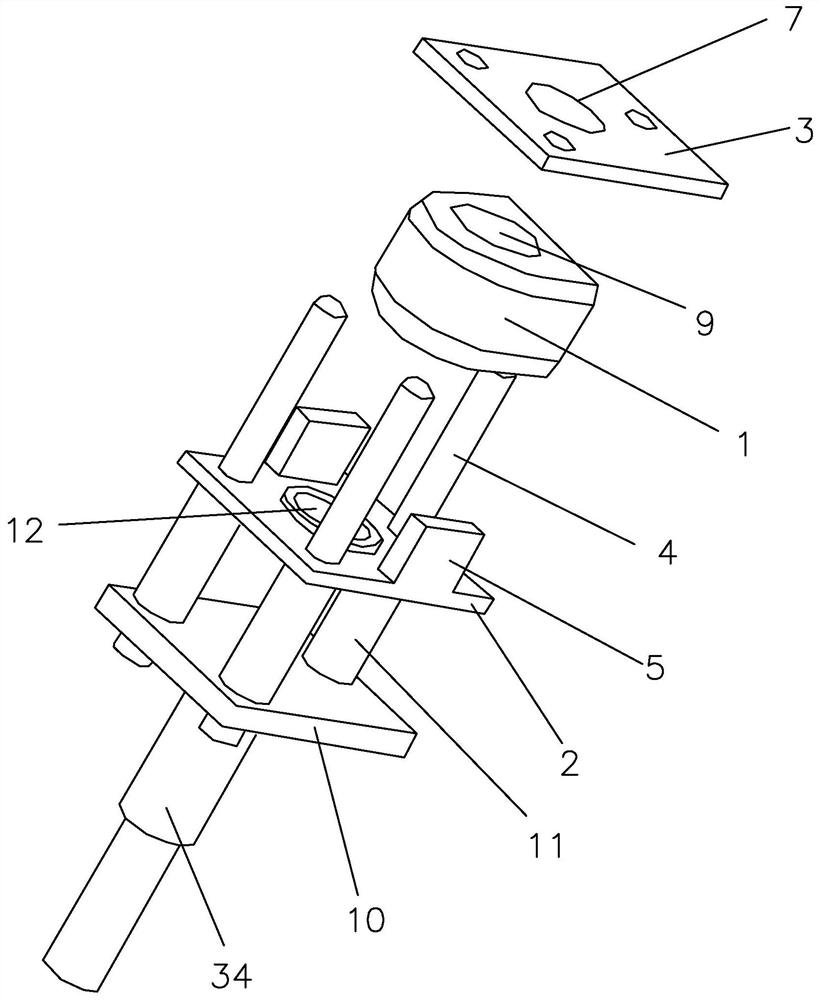

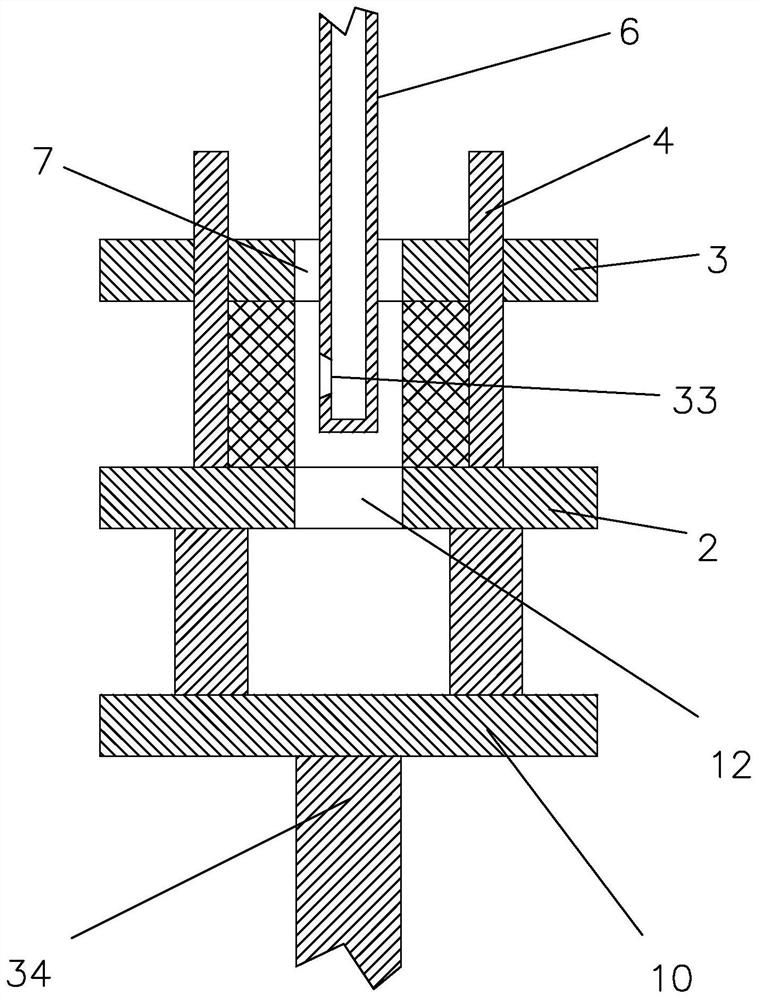

[0027] see Figure 1 to Figure 3 , An auxiliary tool for spraying glue on the lining of the stabilizer bar, characterized in that it includes a fixing mechanism for fixing the lining 1 and a rotating mechanism for rotating the fixing mechanism.

[0028] The fixing mechanism includes a bottom plate 2 for supporting the lower side of the bushing 1, a cover plate 3 covering the upper side of the bushing 1 to realize the upper and lower limit of the bushing 1, and several lower ends fixed on the bottom plate 2 for abutting against the bushing 1. A guide post 4 on the side of the bushing 1 to limit the bushing 1, a number of limit plates 5 fixed on the bottom plate 2 and abutting on the opposite sides of the bushing 1 to prevent the bushing 1 and the bottom plate 2 from rotating relative to each other , a via hole 7 located on the cover plate 3 for inserting the glue gun 6 to spray glue inside the bushing 1 . The fixing mechanism also includes a backing plate 10 located under the ...

Embodiment

[0030] Example principle:

[0031] In this embodiment, the rotating mechanism is the second rotating shaft 34 , the upper end of the second rotating shaft 34 is connected to the lining plate 10 , and the lower end of the second rotating shaft 34 is connected to the motor.

[0032] When in use, remove the cover plate 3, then place the bushing 1 between the guide column 4 and the limit plate 5, then put the cover plate 3 back on, and then insert the glue gun 6 into the via hole 7, and the motor rotates to drive the bushing. The sleeve 1 rotates and the glue gun 6 sprays glue. Since the bushing 1 is in a rotating state, the uniformity of the glue is increased. By controlling the glue spraying time of the glue gun 6, the thickness of the glue can be controlled.

Embodiment 2

[0034] see Figure 4 to Figure 10 , an auxiliary tool for spraying glue on a stabilizer bar bushing, including a fixing mechanism for fixing the bushing 1 and a rotating mechanism for rotating the fixing mechanism.

[0035] The fixing mechanism includes a bottom plate 2 for supporting the lower side of the bushing 1, a cover plate 3 covering the upper side of the bushing 1 to realize the upper and lower limit of the bushing 1, and several lower ends fixed on the bottom plate 2 for abutting against the bushing 1. A guide post 4 on the side of the bushing 1 to limit the bushing 1, a number of limit plates 5 fixed on the bottom plate 2 and abutting on the opposite sides of the bushing 1 to prevent the bushing 1 and the bottom plate 2 from rotating relative to each other , a via hole 7 located on the cover plate 3 for inserting the glue gun 6 to spray glue inside the bushing 1 . The fixing mechanism also includes a backing plate 10 located under the bottom plate 2, a connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com