Automatic glue spraying system

A glue-spraying and automatic technology, applied in the direction of paint spraying room, spraying device, etc., can solve the problem of not being able to spray glue automatically, and achieve the effect of saving glue, spraying glue uniformly, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

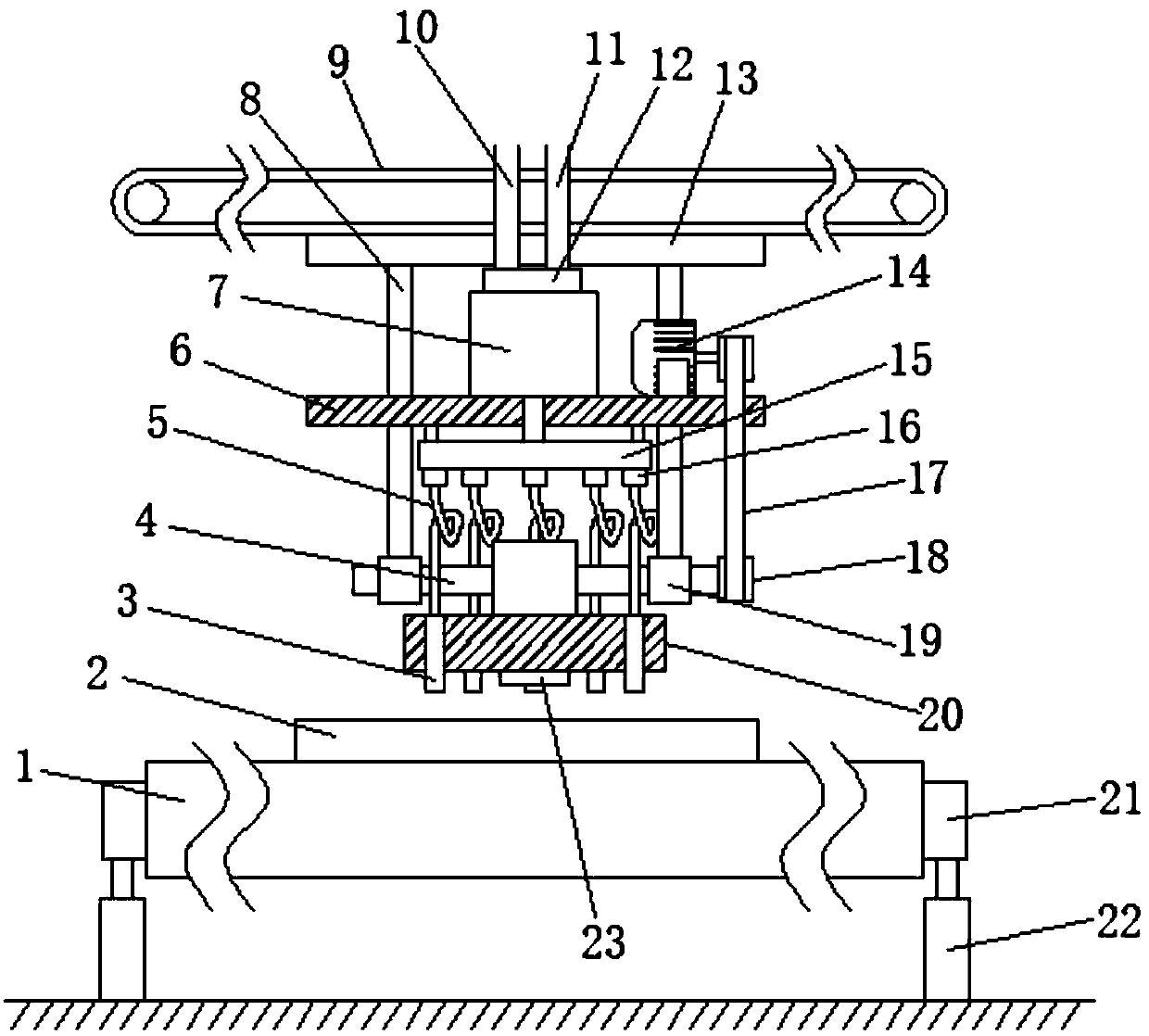

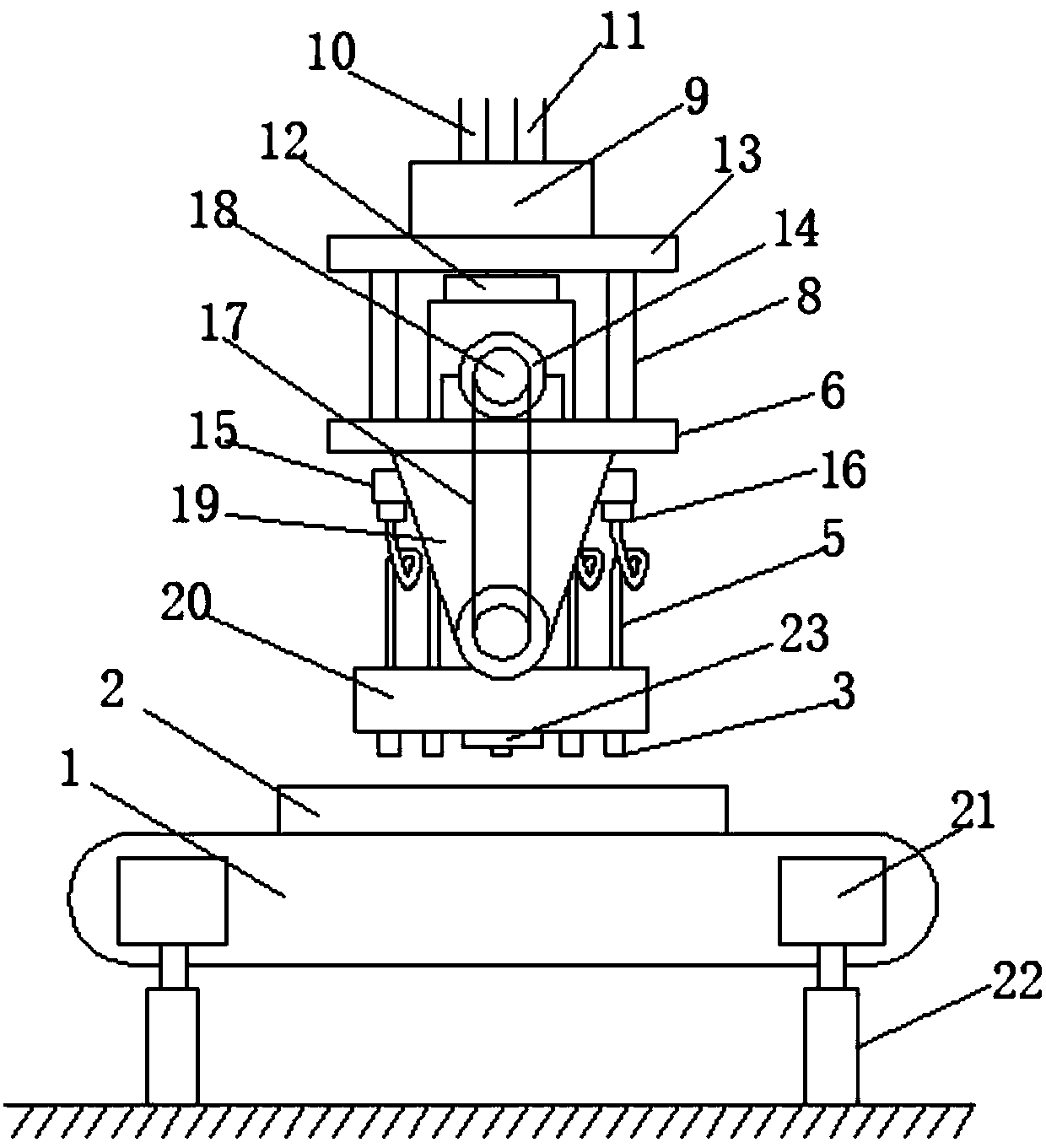

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

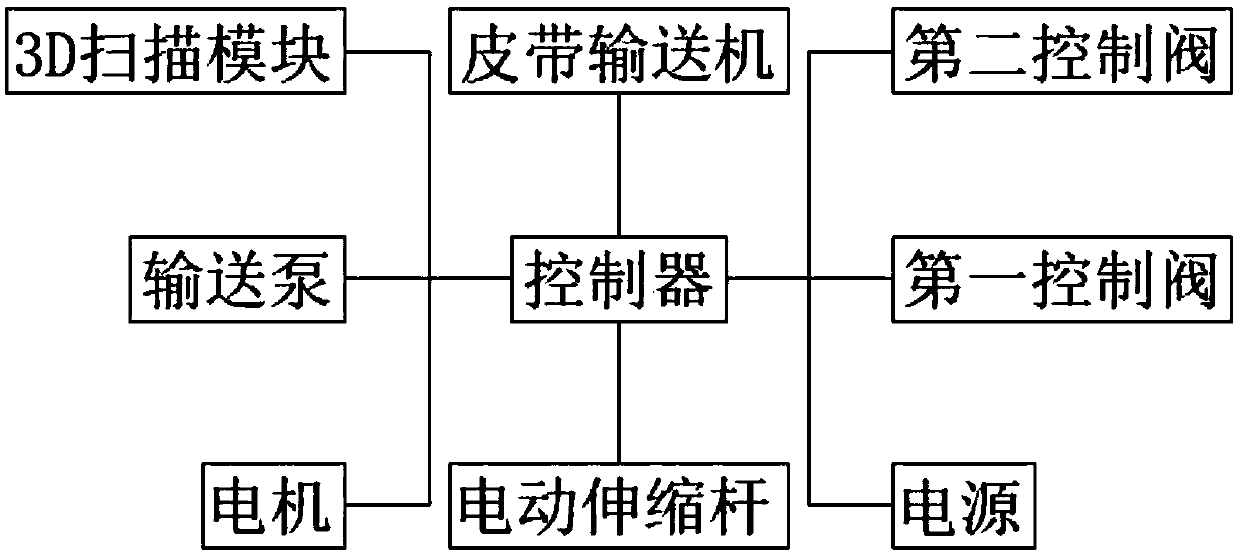

[0018] refer to Figure 1-3 , an automatic glue spraying system, including a first belt conveyor 1 arranged horizontally, the first belt conveyor 1 is fixed on a bracket 21, an electric telescopic rod 22 is vertically connected to the bottom of the bracket 21, and the other end of the electric telescopic rod 22 Fixed on the ground, the electric telescopic rod 22 is connected with the controller by wires. The workpiece 2 is placed on the first belt conveyor 1 for horizontal transportation, and the electric telescopic rod 22 is used to adjust the height of the first belt conveyor 1, thereby indirectly adjusting the distance between the workpiece 2 and the nozzle 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com