Raw material saving device for purifying distillation still blowdown discharged into buffer tank

A technology of buffer tanks and distillation kettles, which is applied in the directions of distillation separation, transportation and packaging, and cleaning of hollow objects. It can solve the problems of waste of resources, reduce the utilization rate of raw materials, and insufficient energy conservation and environmental protection, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

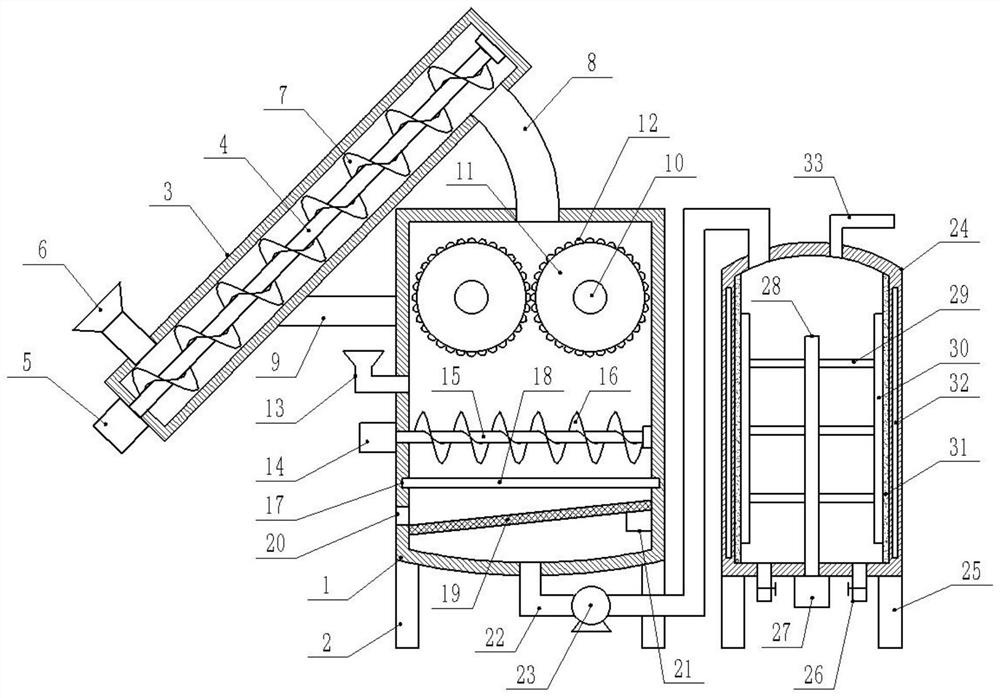

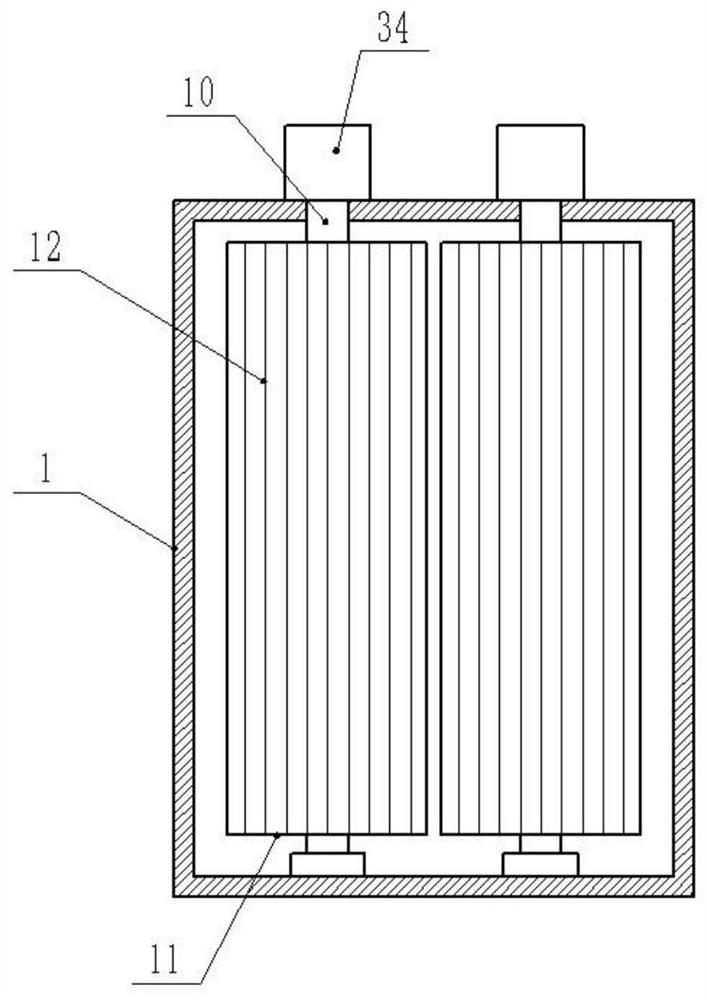

[0021] see Figure 1-5 , a device for discharging sewage from a still kettle into a buffer tank for purification and saving raw materials, comprising a crushing box 1, a feeding mechanism 3, a conveying auger 7, a crushing roller 11, a spiral stirring paddle 16, a purification box 24, a scraper rod 30 and a vacuum insulation Layer 32; four first support rods 2 are evenly distributed below the crushing box 1, and the first support rods 2 and the crushing box 1 are fixedly connected together by welding, and the upper left side of the crushing box 1 is installed There is a feeding mechanism 3, a fixed rod 9 is installed between the middle of the right side of the feeding mechanism 3 and the crushing box 1, a first rotating shaft 4 is installed in the feeding mechanism 3, and a first motor is installed on the left side of the first rotating shaft 4 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com