Locomotive unit brake fatigue test device and test method

A fatigue test and brake technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of large manpower and material consumption, long test period, difficulty in achieving the expected test effect, etc., and achieve automation The effect of low degree and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

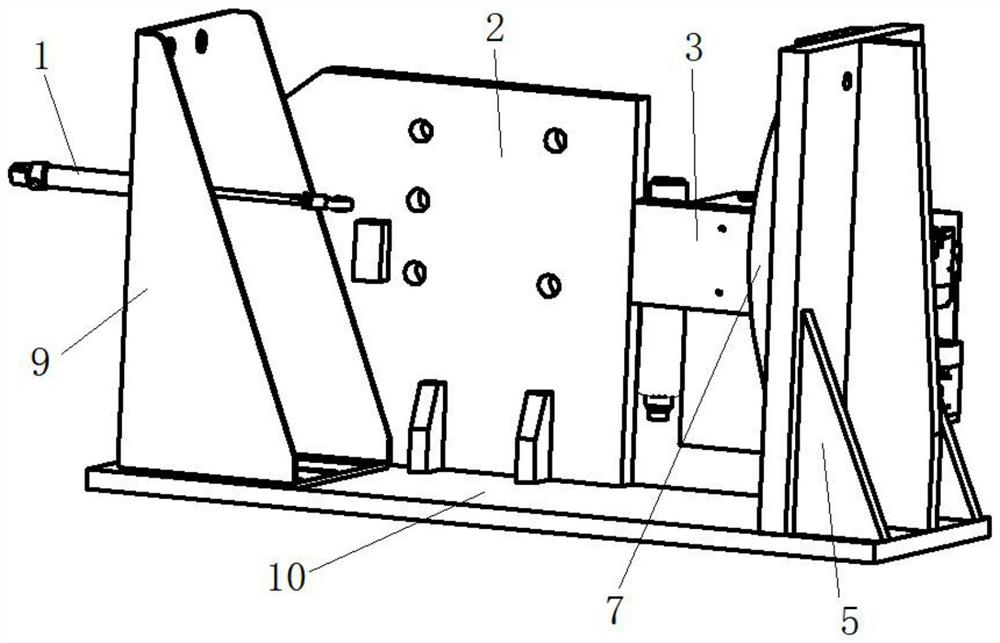

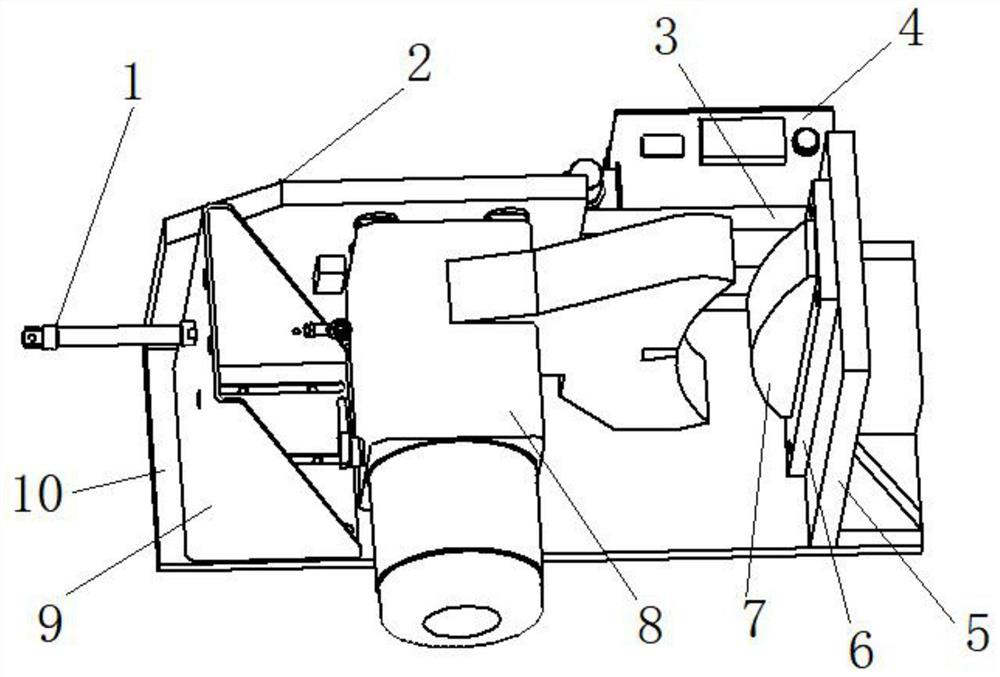

[0032] see Figure 1-2 , a locomotive unit brake fatigue test device, the fatigue test device includes a base, a wheel simulation unit and an action control module, the base is used to install the locomotive unit brake 8, the wheel simulation unit and the action control module are all set On the base, the wheel simulation unit cooperates with the locomotive unit brake 8 to realize wheel brake simulation, and the action control module is used to control the action of the locomotive unit brake 8 .

[0033] The action control module includes a control box 4 and a cylinder 1, the control box 4 is connected to the cylinder 1 and the locomotive unit brake 8, and the control box 4 is used to control the inflation or exhaust of the locomotive unit brake 8, thereby realizing wheel brake simulation. The cylinder 1 is retracted or stretched out to realize the locomotive unit brake 8 simulating the pulling of the wristband solution or the wristband solution homing.

[0034] The piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com