Control method for constant-temperature water return of solid regenerating furnace

A technology of solid heat storage and control method, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of long cycle period, inability to realize constant temperature return water heating, slow response of heating system, etc., and achieve stable return water The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

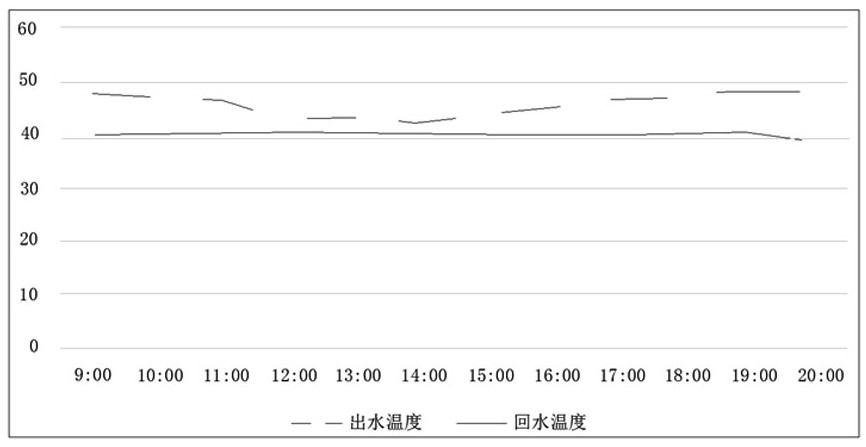

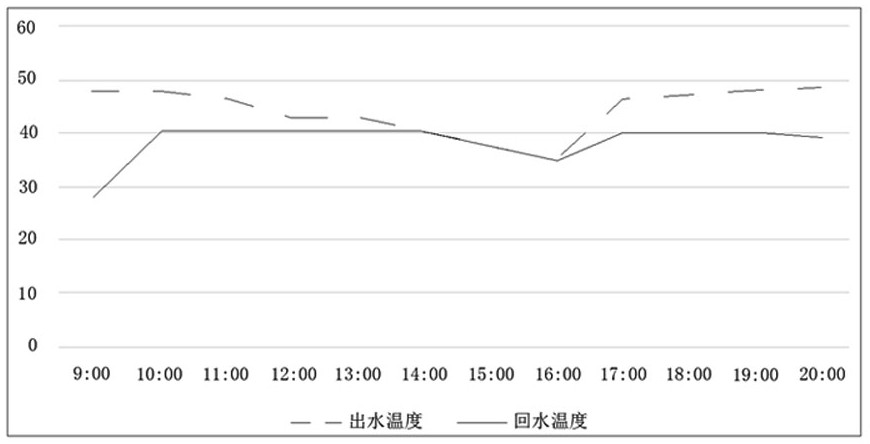

[0044] Example 1, such as figure 1 — figure 2 As shown, the present invention provides a control method for the constant temperature return water of solid heat storage furnace. The return water temperature is the set value, and the ideal real-time changing water outlet temperature value is calculated through the empirical equation. The outlet water temperature can be controlled by single-stage or two-stage PID adjustment realizes precise control, and achieves constant temperature return water by controlling the real-time changing outlet water temperature;

[0045] The equation:

[0046] T 出 =(aT 环 3 +bT 环 2 +cT 环 +d) / F+T 回

[0047] Where a, b, c, d are numbers to be solved under different working conditions;

[0048] T 出 Indicate the water temperature in °C;

[0049] T 回 Refers to the set return water temperature, which is the set value ℃;

[0050] T 环 Refers to the processing value of the ambient temperature, T 环 = (environment measure + 50) / 10;

[0051] F i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com