Pulp and paper control system

A control system, pulping and papermaking technology, applied in general control systems, control/regulation systems, papermaking, etc., can solve problems such as unreasonable program structure, save CPU memory resources, avoid sudden changes, and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be described in further detail below in conjunction with the accompanying drawings:

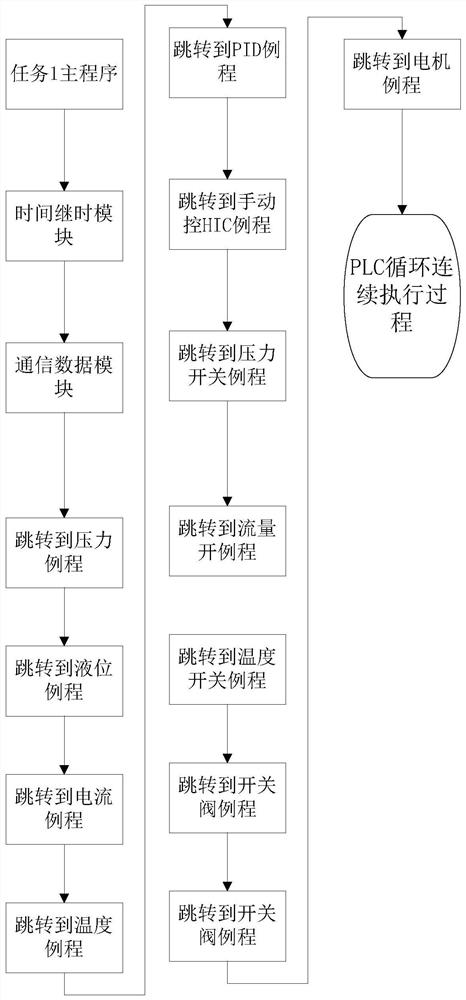

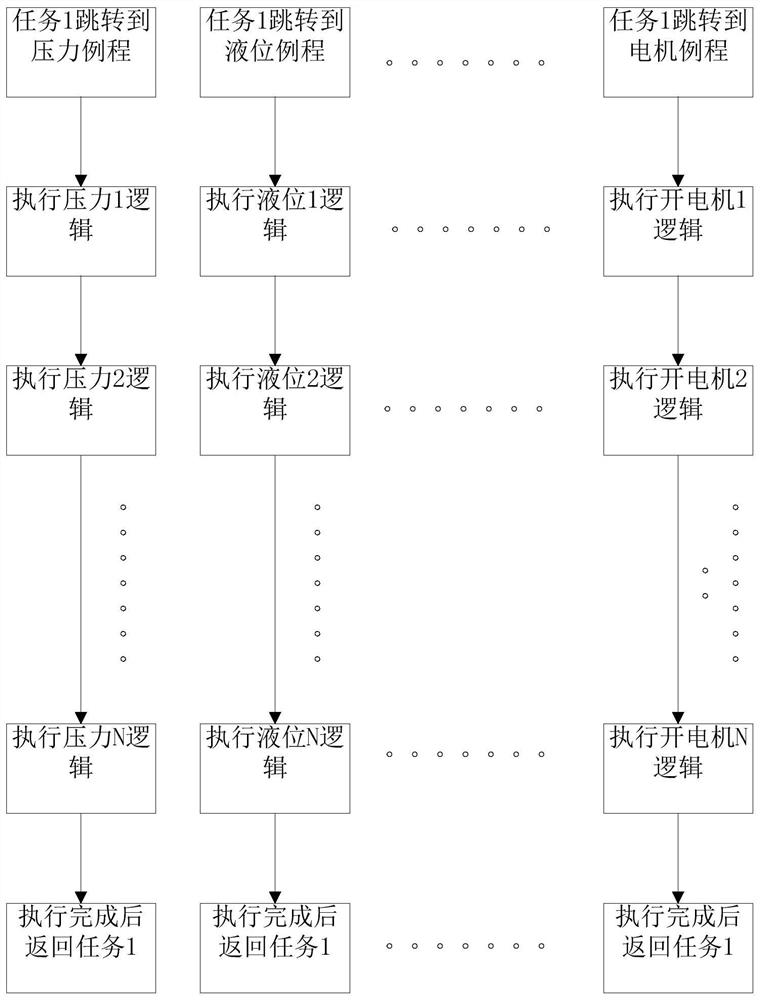

[0105] see Figure 1 to Figure 4 As shown, the problem of unreasonable program structure to be solved by the present invention provides a more reasonable program calling mode, formulates unified function modules according to different devices, and applications of the same type are only called repeatedly or transplanted, and the structure is clear. Multiple background data from other PLCs is so complicated. This control method divides a paper machine into two tasks, the CPU reads all input images first, and scans and executes task 1 and task 2 in sequence. The process of executing task 1: execute the time continuation module --- communication data module --- pressure routine --- liquid level routine --- finally to the motor routine, execute task 1, and return to Execute task 2, and start the execution of task 1 after executing task 2. Execution of each rout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com