Tooth-slot torque optimization design-method of permanent-magnetism brushless direct-current dynamo

A permanent magnet brushless direct current, optimized design technology, applied in computing, electrical digital data processing, instruments, etc., can solve problems such as irreparable energy loss, achieve fast computing speed, high precision of computing results, and reasonable program structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

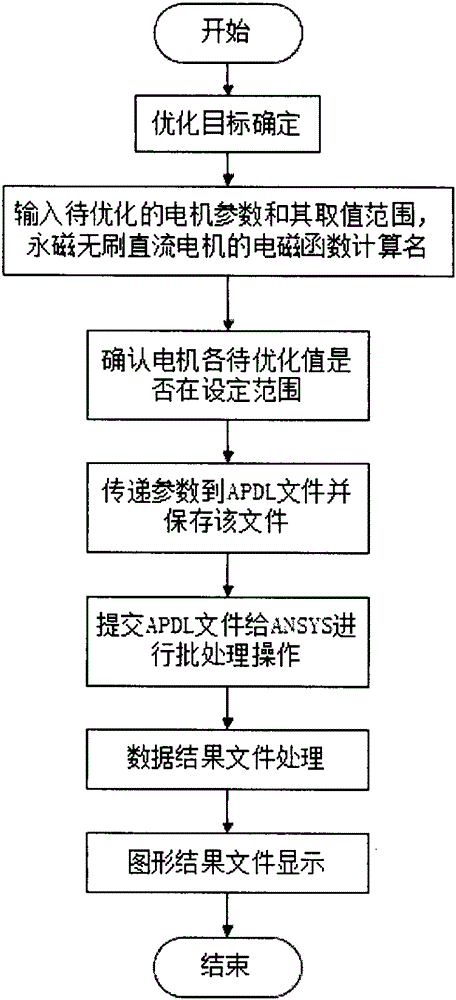

Method used

Image

Examples

Embodiment Construction

[0036] 1. Fractional slot concentrated winding permanent magnet brushless DC motor

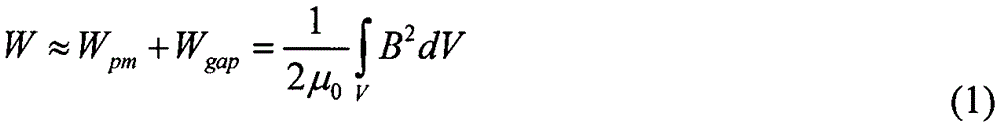

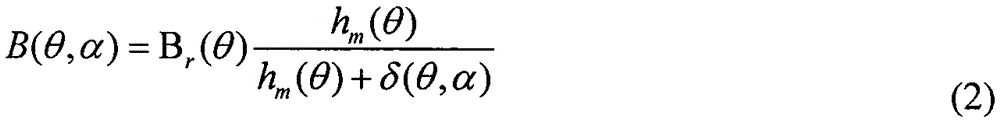

[0037] The permanent magnet motor generates a magnetic field by a permanent magnet, so it does not need an excitation winding and an excitation power supply. It has a simple structure, low loss, high efficiency, and high power density. With the improvement and improvement of the performance of permanent magnet materials, especially the development of rare earth permanent magnet materials, the performance of permanent magnet motors has been further improved, showing the unmatched superiority of electric excitation motors in terms of energy efficiency. Usually, in motor design, the magnetic field is simplified into a magnetic circuit, the air gap flux density of the motor is calculated through the magnetic circuit, and the relevant parameters of the motor are obtained according to empirical formulas. However, the motor parameters obtained in this way are approximate values, and need to add corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com