Salt-containing wastewater recycling device and process

A salty wastewater and process technology, applied in the fields of application, hypochlorite, water/sewage treatment, etc., can solve the problems of complex process, consumption of chemicals, low product value, etc., to maximize resource utilization and conduct electricity The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

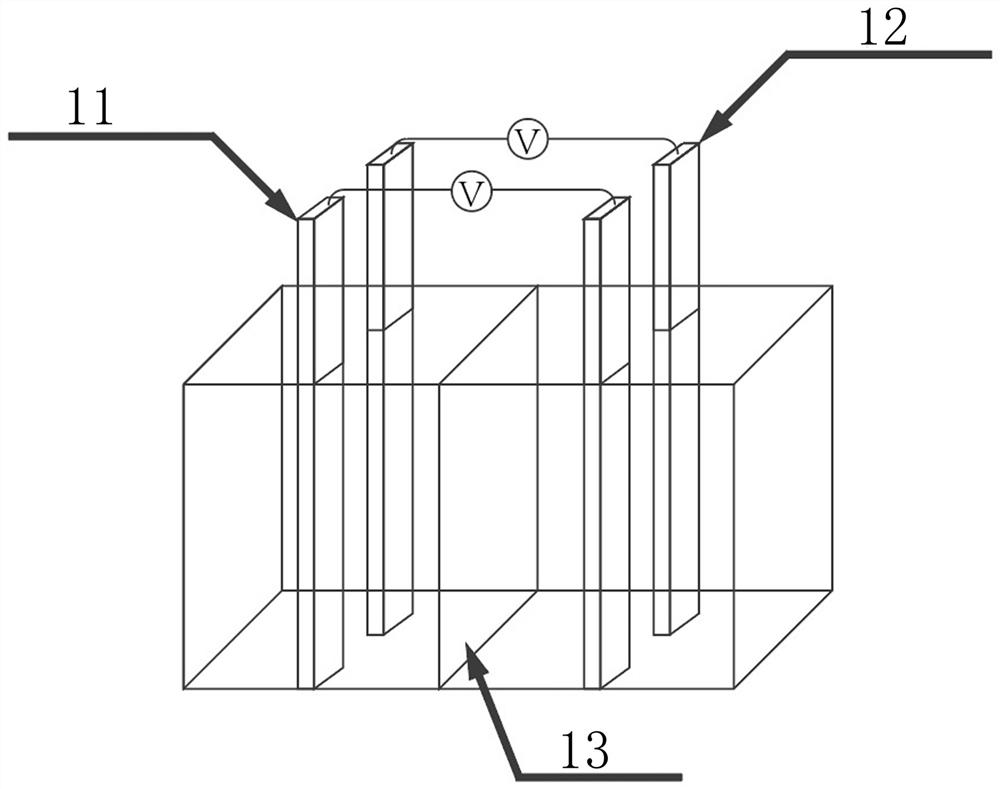

[0023] see figure 1 , a structural schematic diagram of an embodiment of the salty wastewater recovery and reuse device of the present invention. In this embodiment, the device mainly includes an electrolytic cell 1, a hydrogen post-processing device 2, a reaction tank 3 and an external COD detection device (not shown in the figure). Among them, the electrolytic cell 1 is provided with a saline waste water inlet and an electrolyte outlet, the hydrogen post-processing device 2 is connected to the cathode chamber of the electrolytic cell 1, and the reaction cell 3 is connected to the anode chamber of the electrolytic cell 1 and its electrolyte outlet, and the external The COD detection device is mainly used for COD detection of saline wastewater in the whole process.

[0024] As shown in the figure, a buffer water tank 14 can also be arranged before the saline waste water inlet of the electrolytic cell 1, that is, the industrial saline waste water can also be discharged into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com