Device and method for flexible forming of thermoplastic material

A thermoplastic material, flexible forming technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor flexibility, high cost of small batch production, long cycle, etc., to achieve high forming quality, good continuity, reduce The effect of the small step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

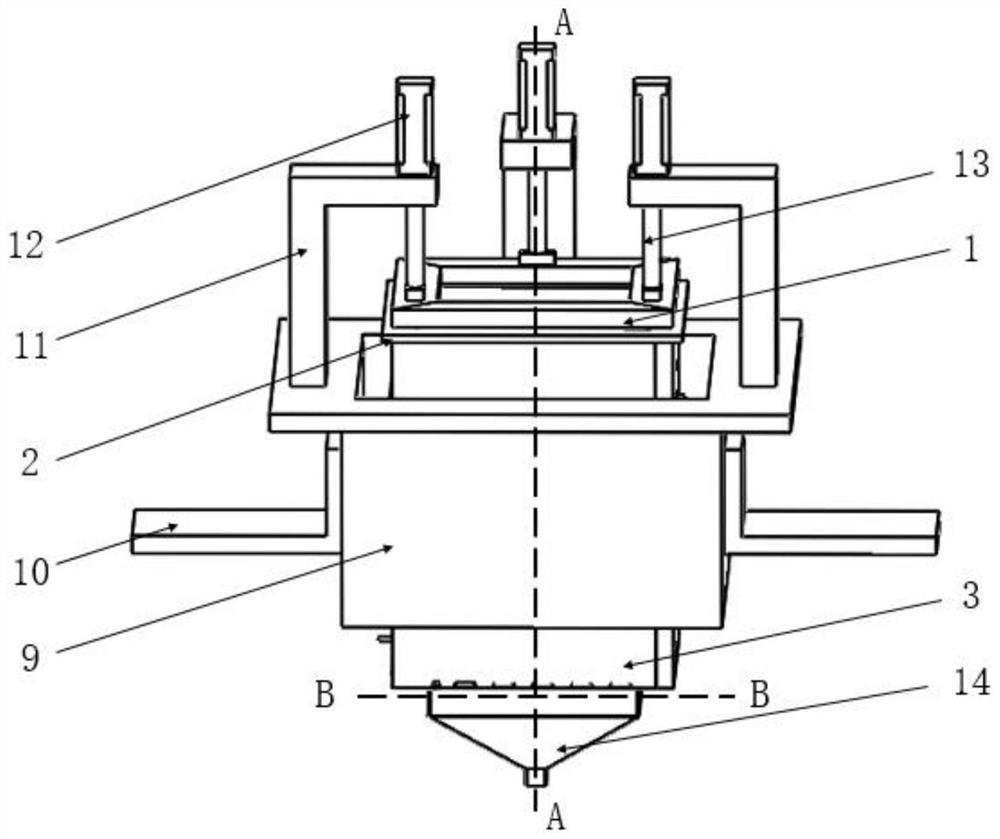

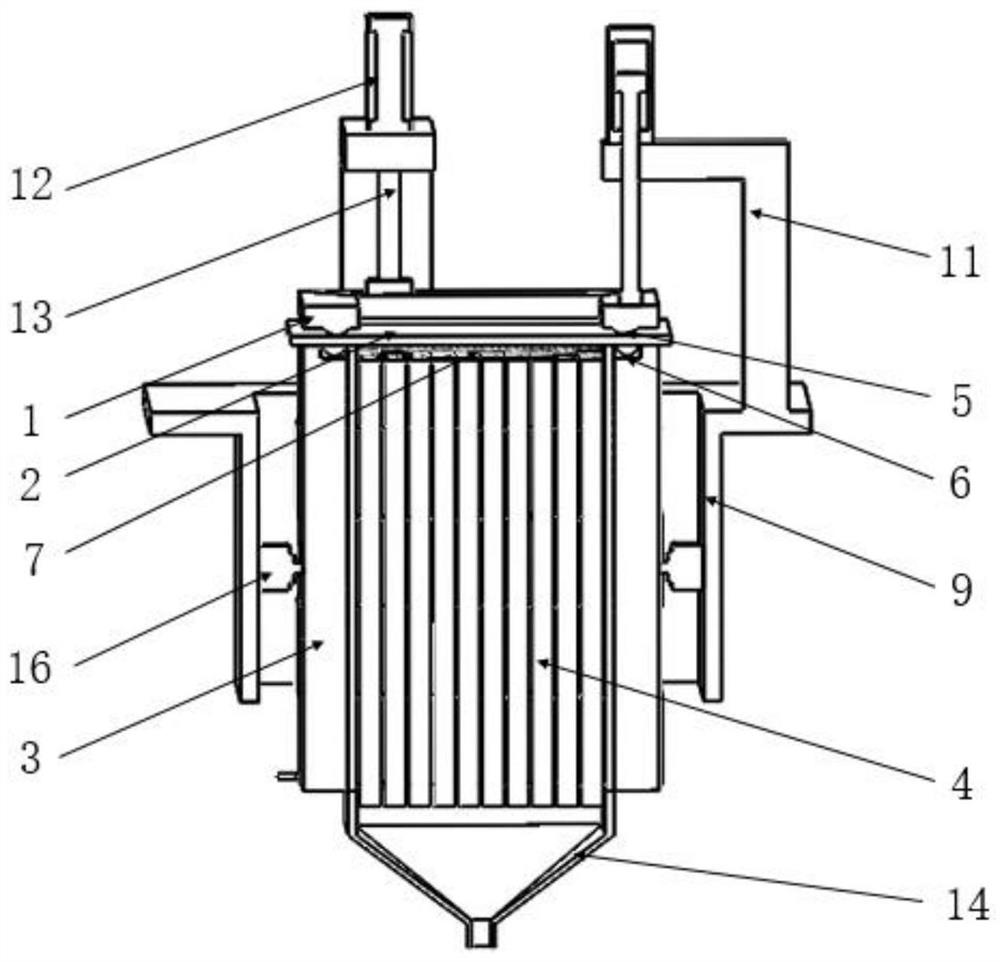

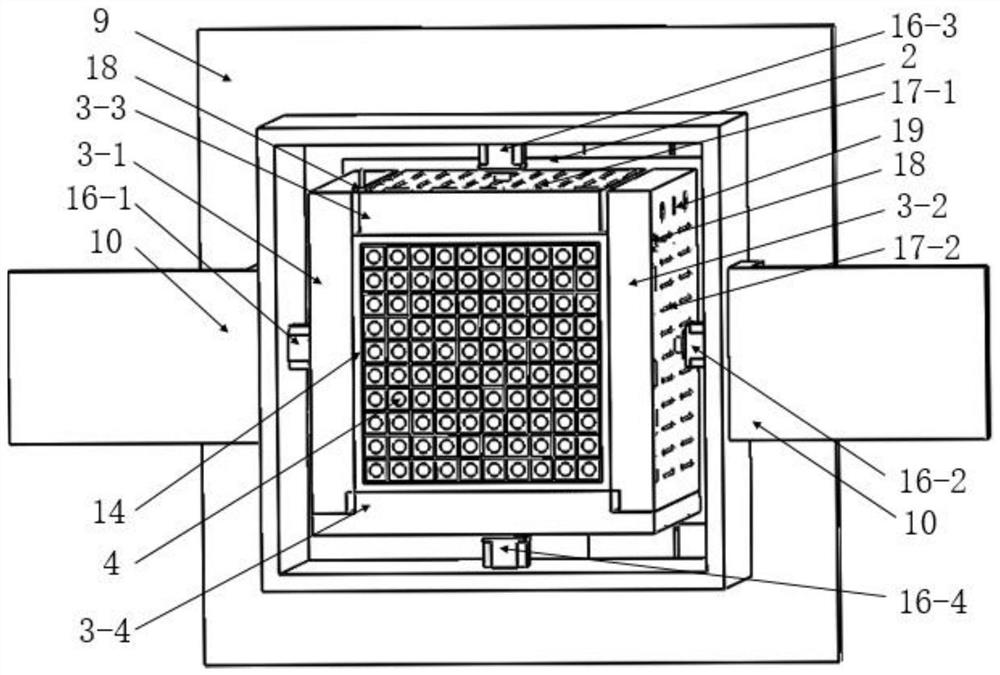

[0048] refer to figure 1 and figure 2 , a thermoplastic material flexible forming device, comprising a multi-point flexible mold, a locking device and a flexible blank-holding system, the multi-point flexible mold is embedded in the locking device, and the flexible blank-holding system is installed on the locking device;

[0049] The multi-point flexible mold includes a pressing plate 3, and there are four pressing plates 3, which are respectively a left pressing plate 3-1, a right pressing plate 3-2, an upper pressing plate 3-3, and a lower pressing plate 3-4, and the four pressing plates form a square Frame, the high-temperature-resistant rubber 14 for sealing is arranged in the square frame, and the high-temperature-resistant rubber 14 for sealing is provided with a plurality of groups of square grids interspersed with carbon fiber wires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com