Raw material dewatering device for preparing rubber and plastic filler by taking lithium slag as raw materials

A dehydration device and raw material technology, applied in heating devices, drying solid materials, lighting and heating equipment, etc., can solve the problems of difficult continuous dehydration treatment, low dehydration efficiency of lithium slag, etc. The effect of dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

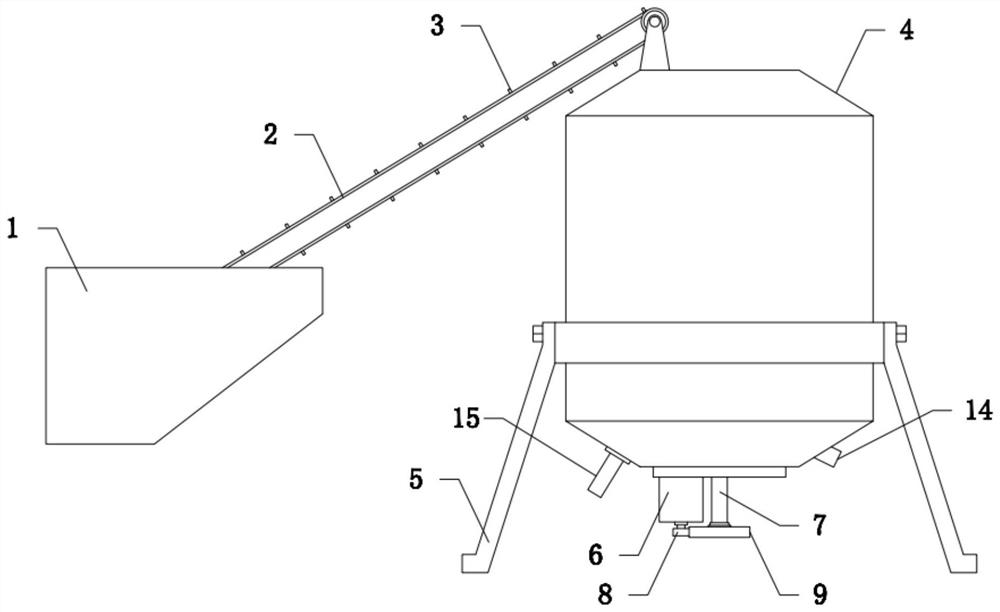

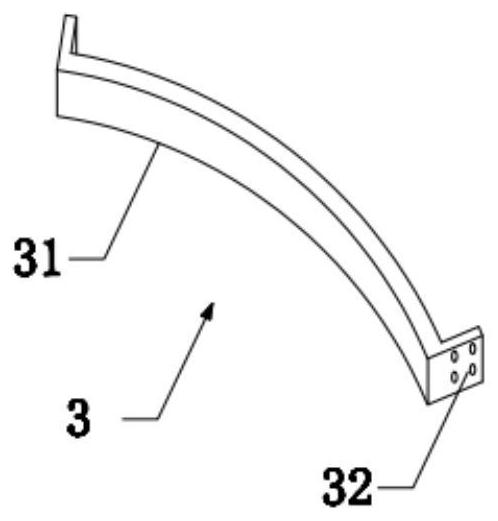

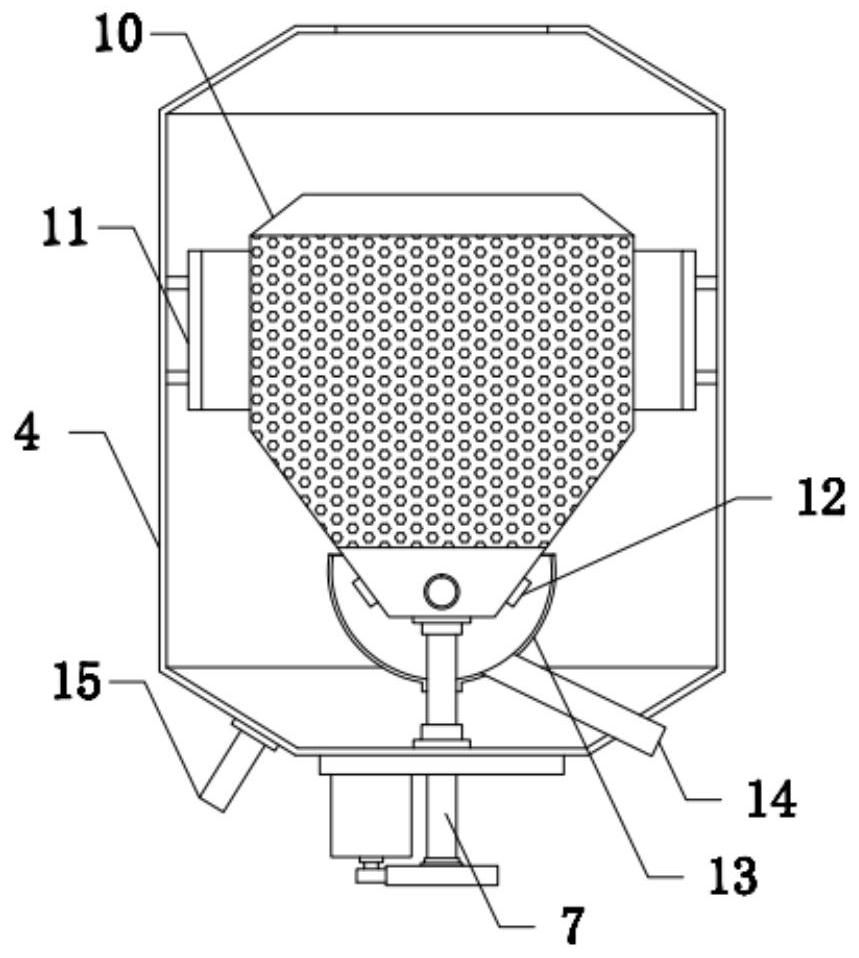

[0026] see Figure 1-3 , the present invention provides a technical solution: a raw material dehydration device for preparing rubber and plastic fillers with lithium slag as raw material, including a storage pool 1, a transmission mechanism 2 and a dehydration bin 4, the lower left end of the transmission mechanism 2 is located in the storage pool 1 Inside, the upper right end of the transmission mechanism 2 is located on the upper side of the dehydration bin 4, the transmission mechanism 2 transfers the materials inside the storage tank 1 to the dehydration bin 4, and the lower surface of the dehydration bin 4 is installed with a Drive motor 6, the bottom end of the output shaft of the drive motor 6 is connected with a drive gear 8, the middle part of the lower surface of the dehydration bin 4 is longitudinally provided with a rotating shaft 7, and the bottom end of the rotating shaft 7 is connected with a driven gear 9, so The driving gear 8 is meshed with the driven gear 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com