Seasoning production equipment for food processing

A technology for production equipment and food processing, applied in the field of seasoning processing, can solve problems such as affecting the quality of seasonings, and achieve the effect of facilitating stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

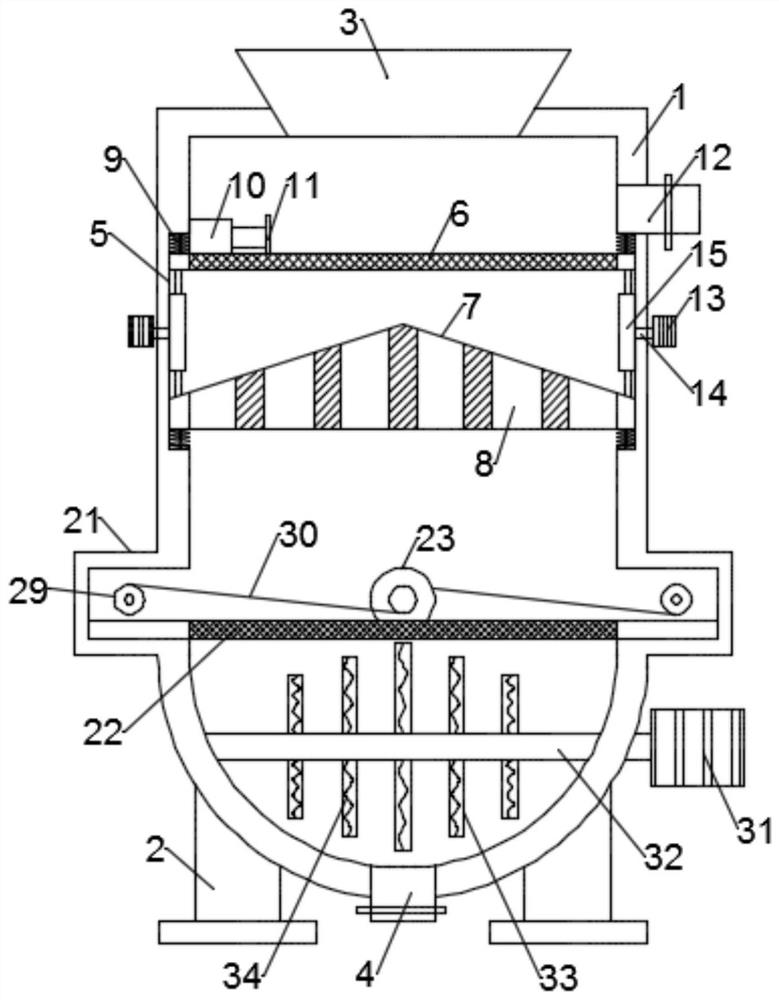

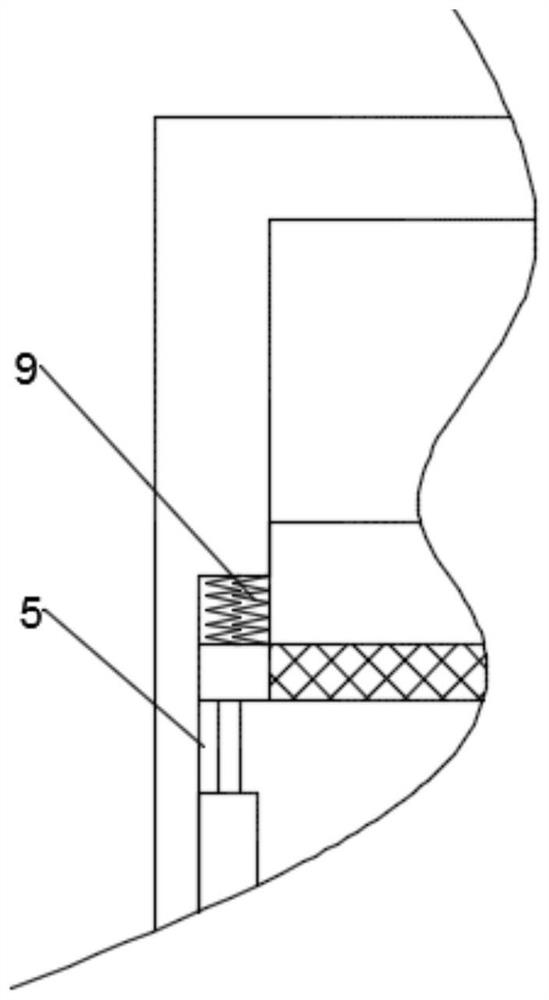

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a seasoning production equipment for food processing, the production equipment includes a production box 1, the bottom of the production box 1 is fixed with support legs 2, and the top of the production box 1 is provided with Feed inlet 3, the bottom end of the production box 1 is provided with a feed opening 4, the inside of the production box 1 is provided with a screen 6 and a distribution frame 7 in sequence, and a discharge chute 8 is provided in the distribution frame 7 ; The bottom of the feeding trough 8 is sequentially provided with a crushing mechanism and a drying and stirring mechanism; a reciprocating mechanism is installed between the screen 6 and the distribution frame 7, and the reciprocating movement is installed on the left and right of the production box 1 In the drive slot 5 provided on the inner wall; both sides of the grinding and crushing mechanism are provided with pullin...

Embodiment 2

[0050] Such as figure 1 As shown, in yet another embodiment provided by the present invention, the dry stirring mechanism includes a third motor 31, the output end of the third motor 31 is drivingly connected to the third shaft 32 through a coupling, and the third shaft 32 is rotatably installed below the grinding and crushing mechanism, and a stirring paddle 33 is fixed on the third rotating shaft 32, and a heating wire 34 is installed inside the stirring paddle 33.

[0051] Start the third motor 31, the third motor 31 drives the stirring paddle 33 to rotate through the third rotating shaft 32, so that the stirring paddle 33 can be used to continuously stir and mix the material, and the heating wire 34 is used to heat and dry the material at the same time. dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com