EPS line shaping equipment for engineering construction

A line and engineering technology, applied in the field of EPS line shaping equipment for engineering construction, can solve the problems of uneven mixing of aggregates, difficult drying and curing of aggregates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

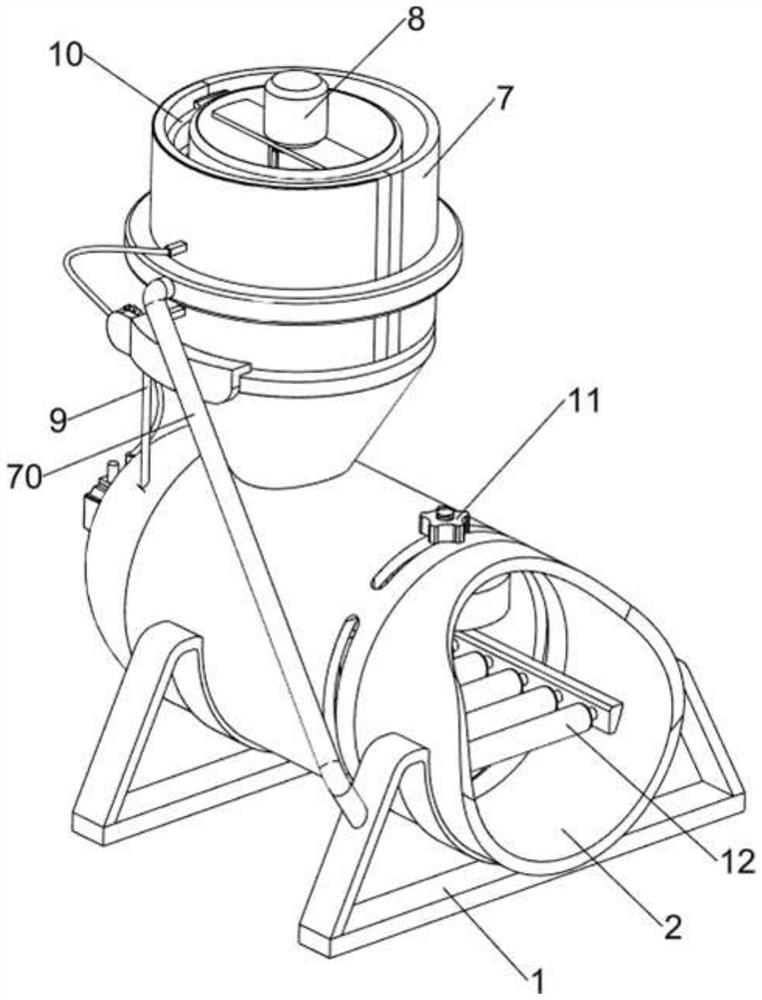

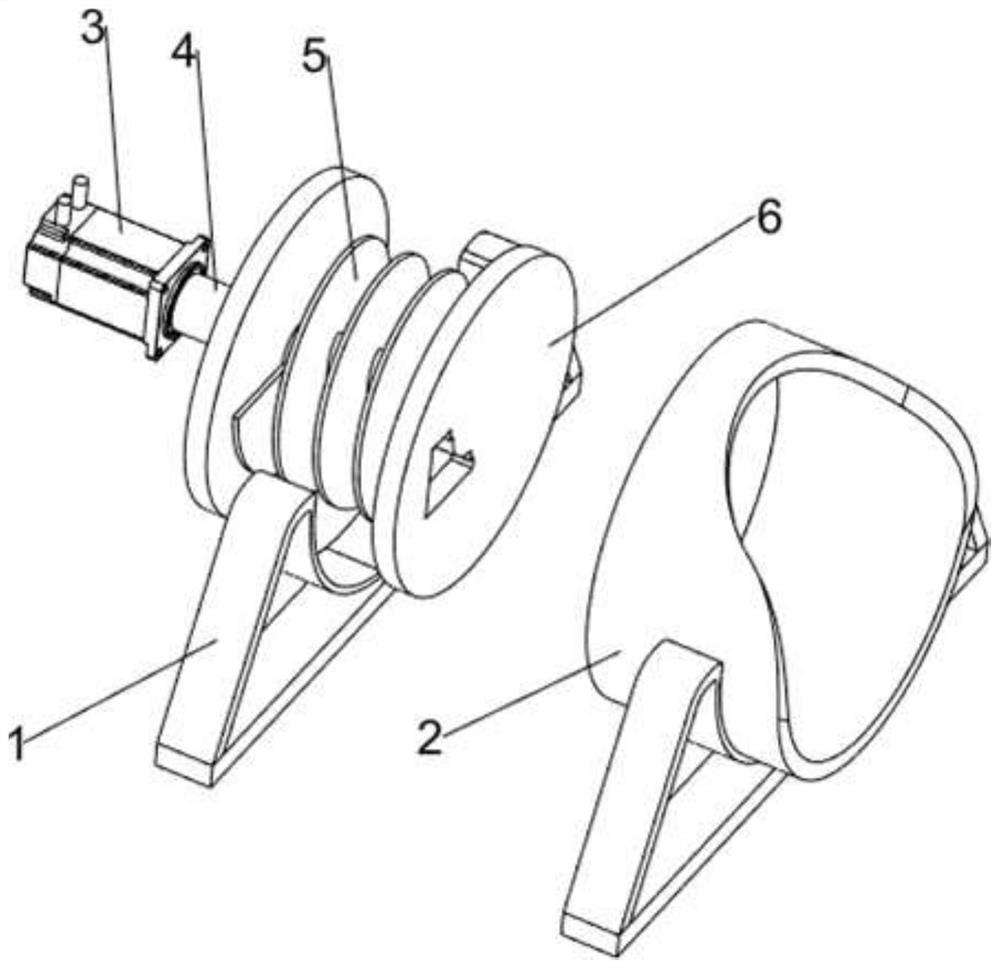

[0064] A kind of EPS line shaping equipment for engineering construction, such as Figure 1-2 As shown, it includes a first support frame 1, a connecting barrel 2, a servo motor 3, a first rotating shaft 4, a first feeding worm 5, a model plate 6, a storage mechanism 7 and a stirring mechanism 8, and two first support frames 1 There is a connecting barrel 2 between the tops, a servo motor 3 is arranged on the rear side of the connecting barrel 2, the servo motor 3 passes through the rear side of the connecting barrel 2, the output end of the servo motor 3 is provided with a first rotating shaft 4, and the first rotating shaft 4 is A first feeding worm 5 is provided, a mold plate 6 is arranged inside the connecting barrel 2, a material storage mechanism 7 is arranged on the rear side of the top of the connecting barrel 2, and a stirring mechanism 8 is arranged in the material storage mechanism 7.

[0065] The staff puts the aggregate in the material storage mechanism 7, and the...

Embodiment 2

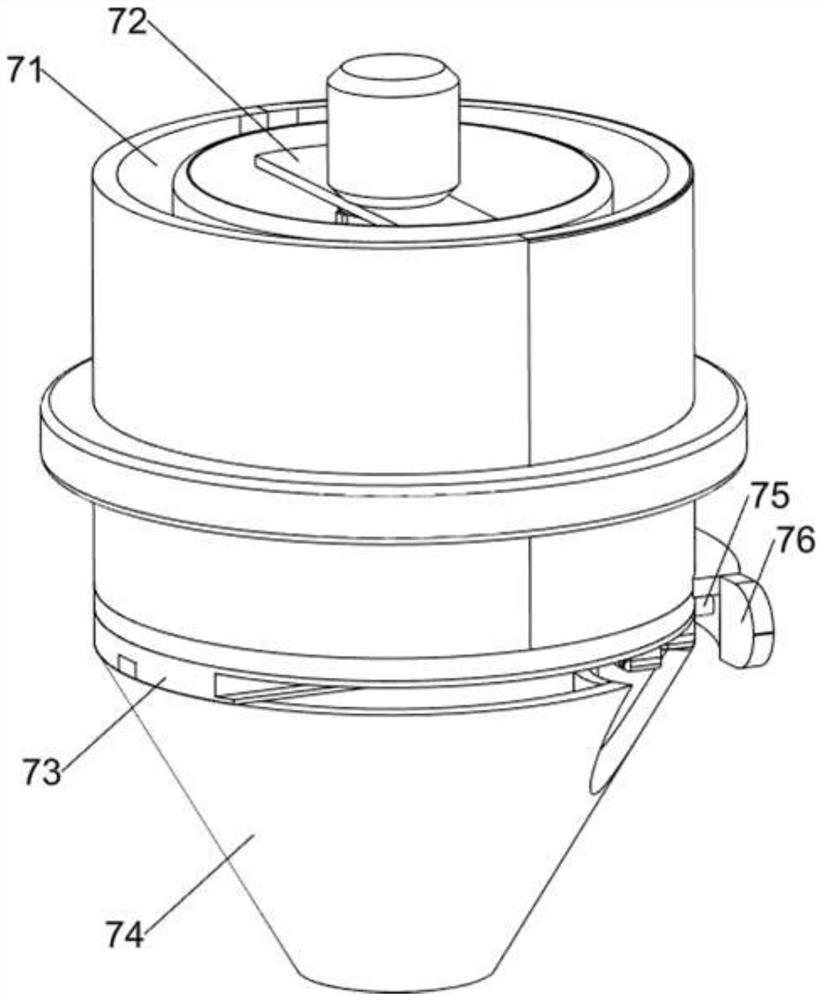

[0067] On the basis of Example 1, such as Figure 3-6 As shown, the material storage mechanism 7 includes a second support frame 70, a material storage bucket 71, a support plate 72, a baffle plate 73, a material receiving bucket 74, a guide rod 75 and a first connecting plate 76, and the first support frame on the front side 1 is provided with a second support frame 70, the second support frame 70 is provided with a storage tank 71, the storage tank 71 is provided with a support plate 72, the rear side of the top of the connecting bucket 2 is provided with a receiving bucket 74, and the connecting bucket 2 A first connecting plate 76 is arranged in the middle of the left side, and two guide rods 75 are arranged on the first connecting plate 76 , and a baffle plate 73 is slidably arranged between the guide rods 75 .

[0068] Stirring mechanism 8 includes torque motor 80, the second rotating shaft 81, the first stirring rod 82, the second stirring rod 83 and the second feeding ...

Embodiment 3

[0071] On the basis of Example 2, such as Figure 6-10 As shown, an opening and closing mechanism 9 is also included, and the opening and closing mechanism 9 includes a limit plate 90, a twist shaft 91, a third rotating shaft 92, a first bevel gear assembly 93, a fourth rotating shaft 94, a pulley assembly 95 and a second bevel gear Component 96, a limiting plate 90 is provided on the material receiving barrel 74, and a twist shaft 91 is arranged in rotation between the limiting plate 90 and the first connecting plate 76, and the baffle plate 73 is matched with the twist shaft 91, and the left rear of the top of the connecting barrel 2 The side rotation type is provided with a third shaft 92, and the twist shaft 91 and the second shaft 81 are provided with a first bevel gear assembly 93. The first bevel gear assembly 93 is composed of two bevel gears, and the bevel gears are respectively connected to the twist shaft 91 and the second shaft 81. On the second rotating shaft 81, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com