Punching assembly and punching device

A technology of hole components and fixed components, which is applied in the field of medical devices, can solve the problems of time-consuming, laborious, dangerous, stab wounds, etc., and achieve the effect of increasing the success rate, uniform hole spacing, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment specifically elaborates on the punching device used for fixing the wound cover and punching the wound cover. Wound coverings include autologous skin, allogeneic skin, heterogeneous skin, artificial dermis scaffolds and various special dressings, etc., which are used to transplant to the wound surface of the human body during surgery.

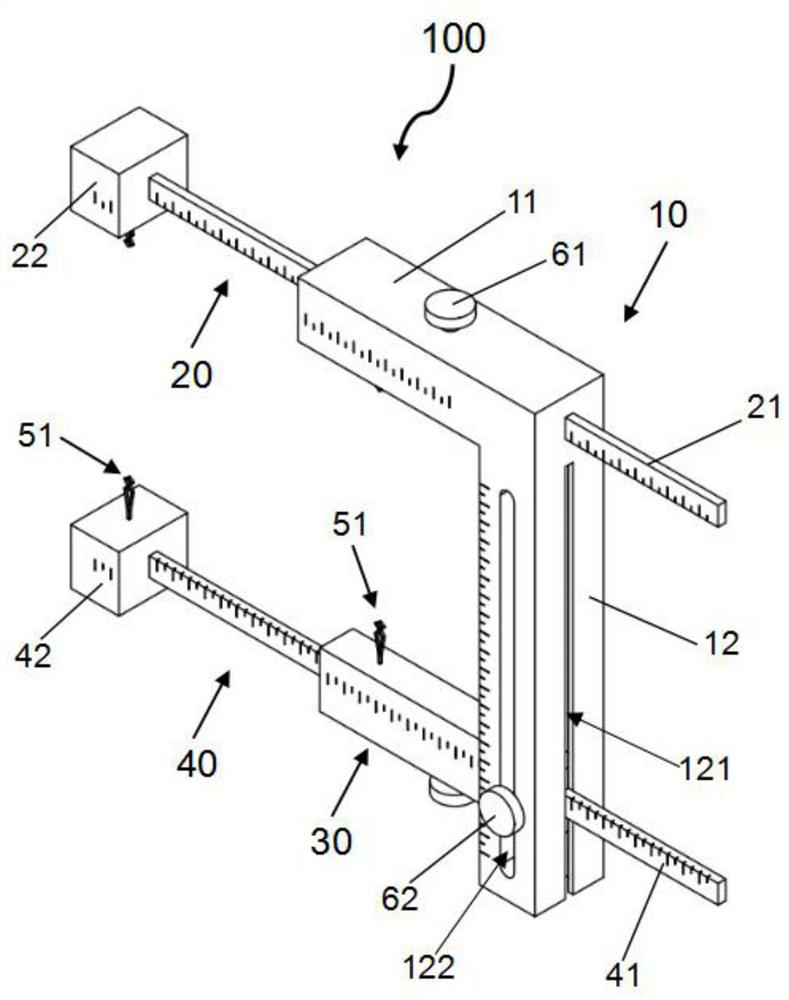

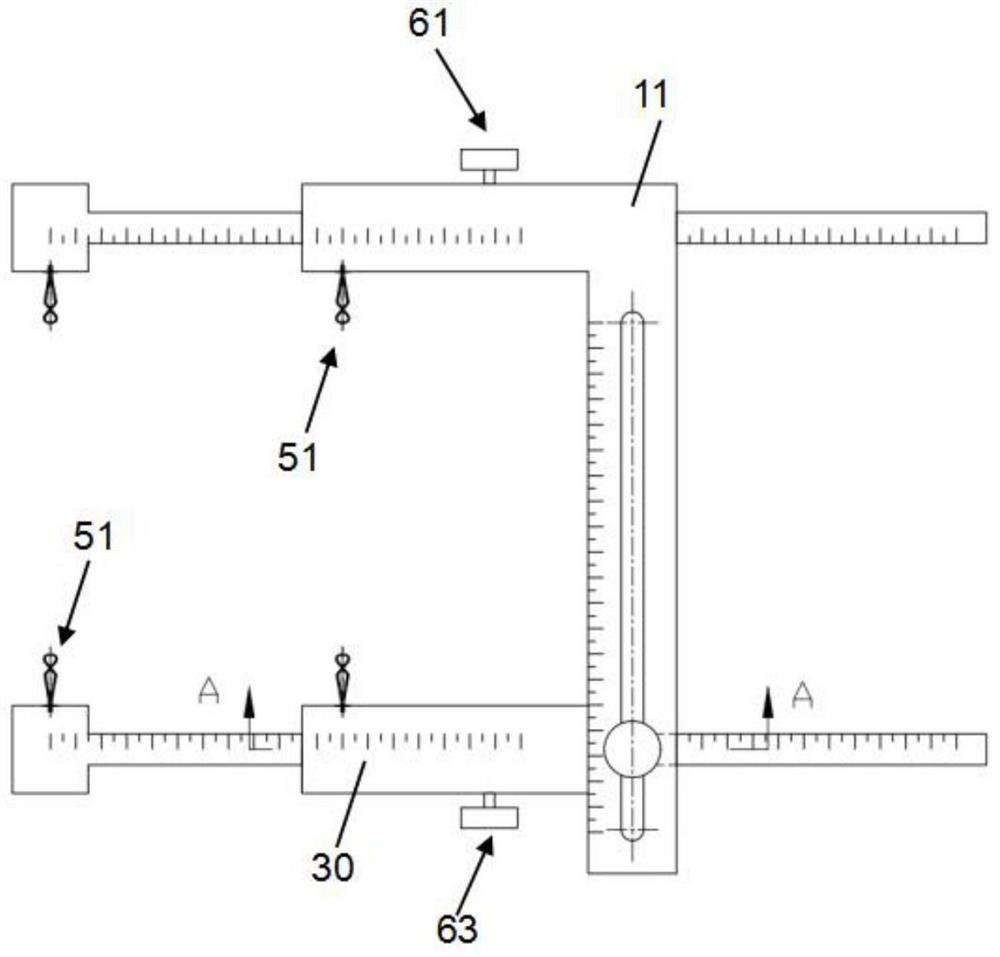

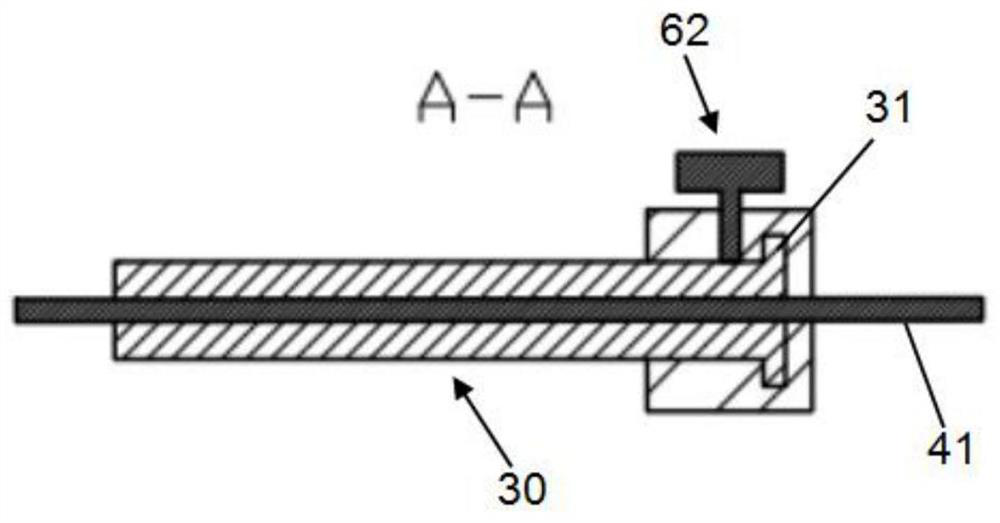

[0034] figure 1 is a structural schematic diagram of the adjustable frame in Embodiment 1 of the present invention, figure 2 is the front view of the adjustable frame in Embodiment 1 of the present invention, image 3 yes figure 2 The A-A profile in the, Figure 4 It is a schematic structural view of the handkerchief clip in Embodiment 1 of the present invention, Figure 5 is a schematic structural view of the punching assembly in Embodiment 1 of the present invention.

[0035] Such as Figure 1-5 As shown, the punching device includes a fixing component 100 and a punching component 200 .

[0036] The fixing assem...

Embodiment 2

[0079] In this embodiment, the same numbers are given to the same structures as in Embodiment 1, and these structures have the same functions and effects as in Embodiment 1, and will not be repeated here.

[0080] The punching device of this embodiment includes a fixing assembly 100 and a punching assembly 300 , the structure of the fixing assembly 100 is the same as that of Embodiment 1, and will not be repeated here.

[0081] Figure 6 It is a structural schematic diagram of the punching assembly in Embodiment 2 of the present invention.

[0082] Such as Figure 6 As shown, the punching assembly 300 includes a tool holder 201 , an adjusting plate 302 and a distance locking member 203 .

[0083]One end of the adjusting plate 302 is fixed on the fixed arm 213 by a rivet, and the other end is detachably connected to the moving arm 214 by a distance locking member 203 . Along the extending direction of the adjusting plate 302 , an adjusting groove 303 penetrating up and down ...

Embodiment 3

[0091] In this embodiment, the same numbers are assigned to the same structures as those in Embodiments 1 and 2. These structures have the same functions and effects as those in Embodiment 2, and will not be repeated here.

[0092] The punching device of this embodiment includes a fixing assembly 100 and a punching assembly 400 , the structure of the fixing assembly 100 is the same as that of Embodiment 1, and will not be repeated here.

[0093] Figure 7 It is the structural representation of the perforated assembly in embodiment 3; Figure 8 yes Figure 7 A partial enlargement of the .

[0094] Such as Figure 7 , 8 As shown, the punching assembly 400 and the punching assembly 300 include a tool holder 201 , an adjusting plate 401 , a distance locking member 203 and a corrugated clamping plate 402 .

[0095] One end of the adjusting plate 401 is fixed on the fixed arm 213 by a rivet, and the other end is detachably connected to the moving arm 214 by the distance locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com