Power failure detection device

A detection device, power failure technology, applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of reduced service life of internal electronic equipment, incompatibility between heat dissipation and sealing, poor heat dissipation of power detection device, etc., to achieve Keep clean and dry, good heat dissipation, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

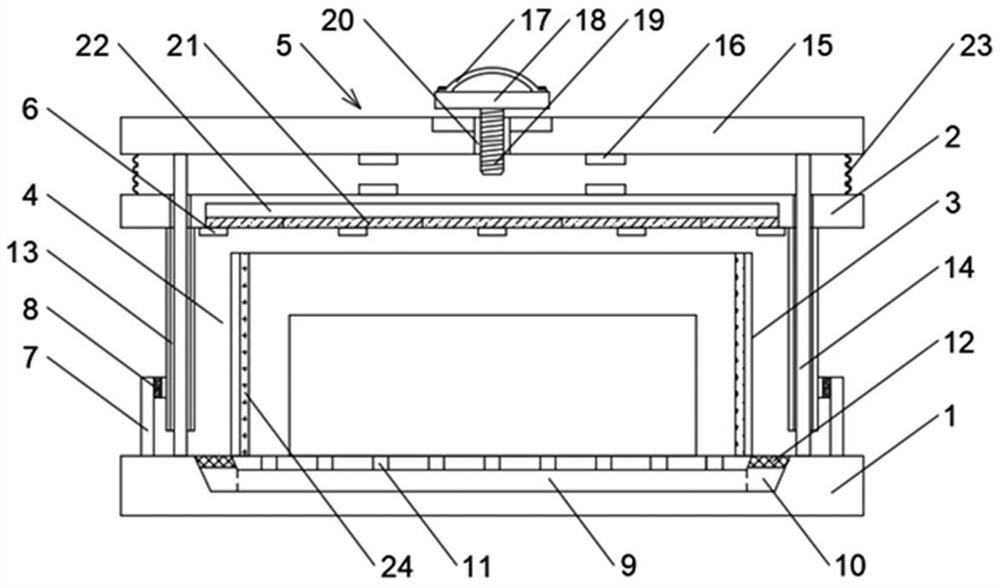

[0030] Such as figure 1 As shown, the present invention discloses a power failure detection device, including a base 1 for installing electronic detection components, and an outer shell 2 movably connected to the base 1, the bottom of the outer shell 2 is provided with an opening; the outer shell 2 can be subjected to Drive up to the open position along the direction away from the base 1, or dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com