Direct-driven electric workover rig

An electric workover rig, direct-drive technology, applied in drilling equipment, earthmoving, drill pipe, etc., can solve the problems of low transmission efficiency, complex transmission structure, etc. Effect of installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

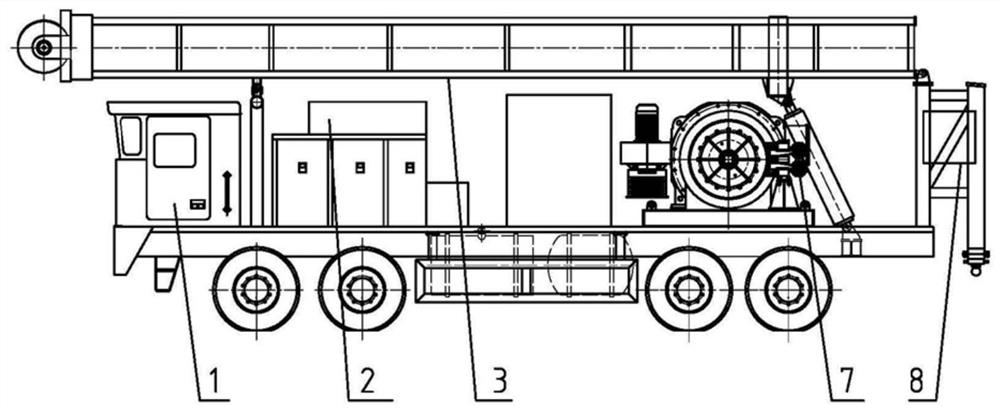

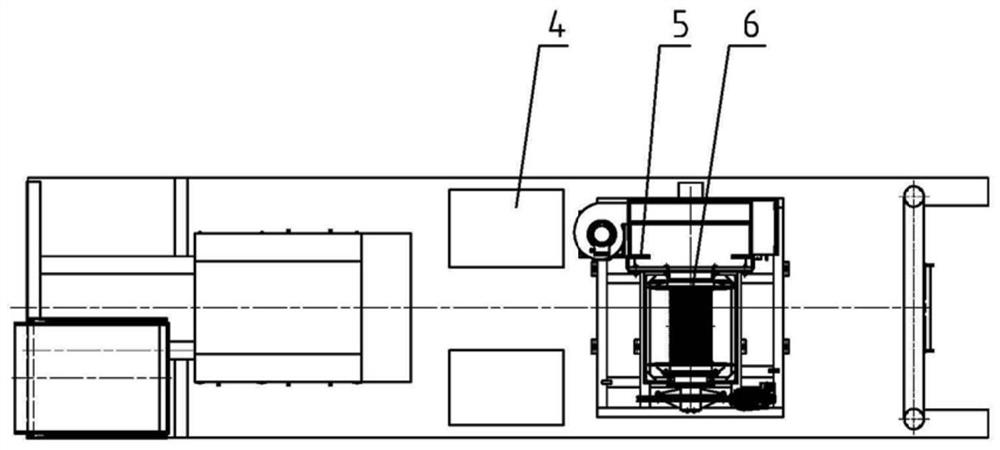

[0025] A direct drive electric workover rig, such as figure 1 , figure 2 As shown, it includes a chassis 1, a derrick 3, an AC frequency conversion disc motor 5, a winch 6, and an air control disc brake 7, wherein the chassis 1 is connected with a derrick 3, a frequency conversion disc motor 5, and a winch 6 respectively. The motor 5 is connected in transmission with the winch 6, and the winch 6 is connected with an air control disc brake 7. Among them, it also includes a braking resistor 2, an electric control cabinet 4, and an operating console 8, wherein the braking resistor 2 is arranged in the power supply circuit of the AC variable frequency disc motor 5; the electric control cabinet 4 is fixedly connected to the chassis 1, and the electric The control cabinet 4 communicates with the AC frequency conversion disc motor 5 and the air control disc brake 7 respectively; the operating console 8 is fixedly connected to the chassis 1 . Described winch 6 has drum, has Ribas r...

Embodiment 2

[0028] A direct drive electric workover rig, such as figure 1 , figure 2 As shown, it includes a chassis 1, a derrick 3, an AC frequency conversion disc motor 5, a winch 6, and an air control disc brake 7, wherein the chassis 1 is connected with a derrick 3, a frequency conversion disc motor 5, and a winch 6 respectively. The motor 5 is connected in transmission with the winch 6, and the winch 6 is connected with an air control disc brake 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com