Novel chemical hydrogen production reactor

A hydrogen production reactor and chemical technology, applied in the direction of hydrogen production, etc., can solve the problems of difficult continuous and stable hydrogen production, low catalyst utilization rate, transportation, and inconvenient portability, etc., achieve good preheating effect, simple structure, and improve Effect of heat transfer level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

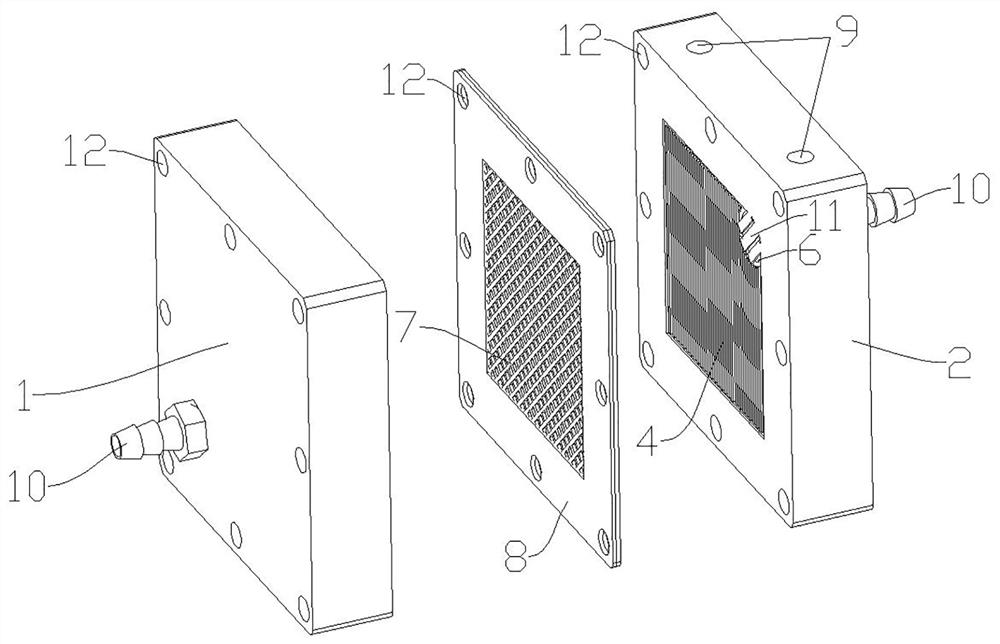

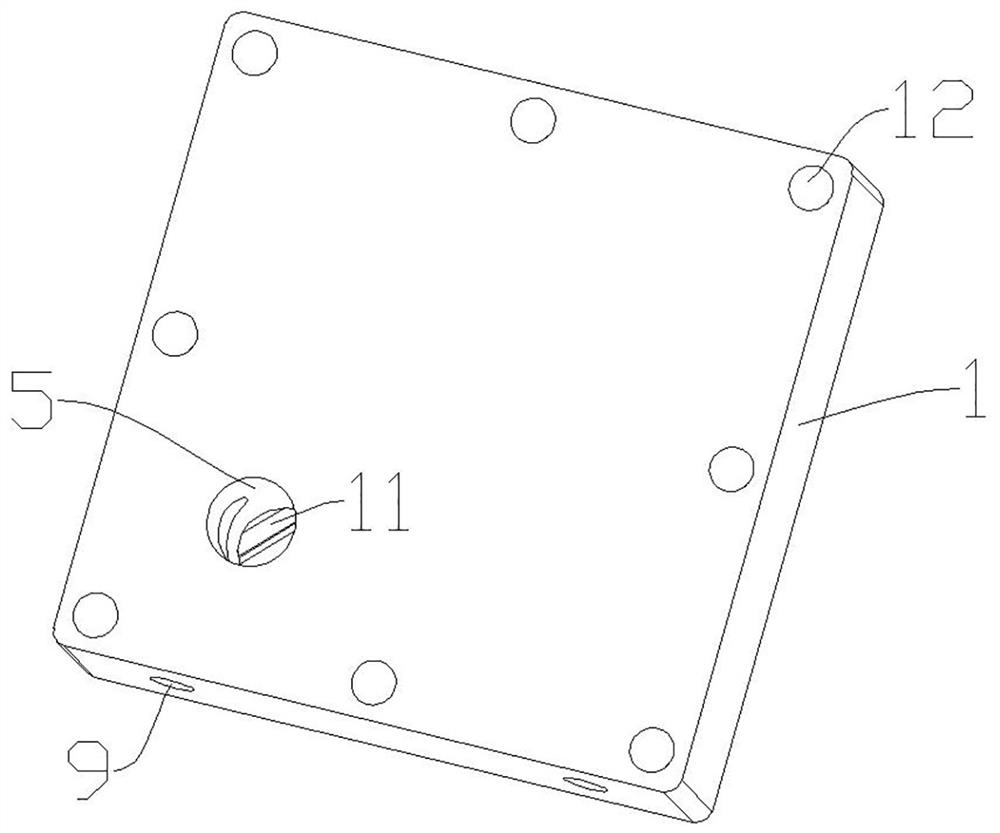

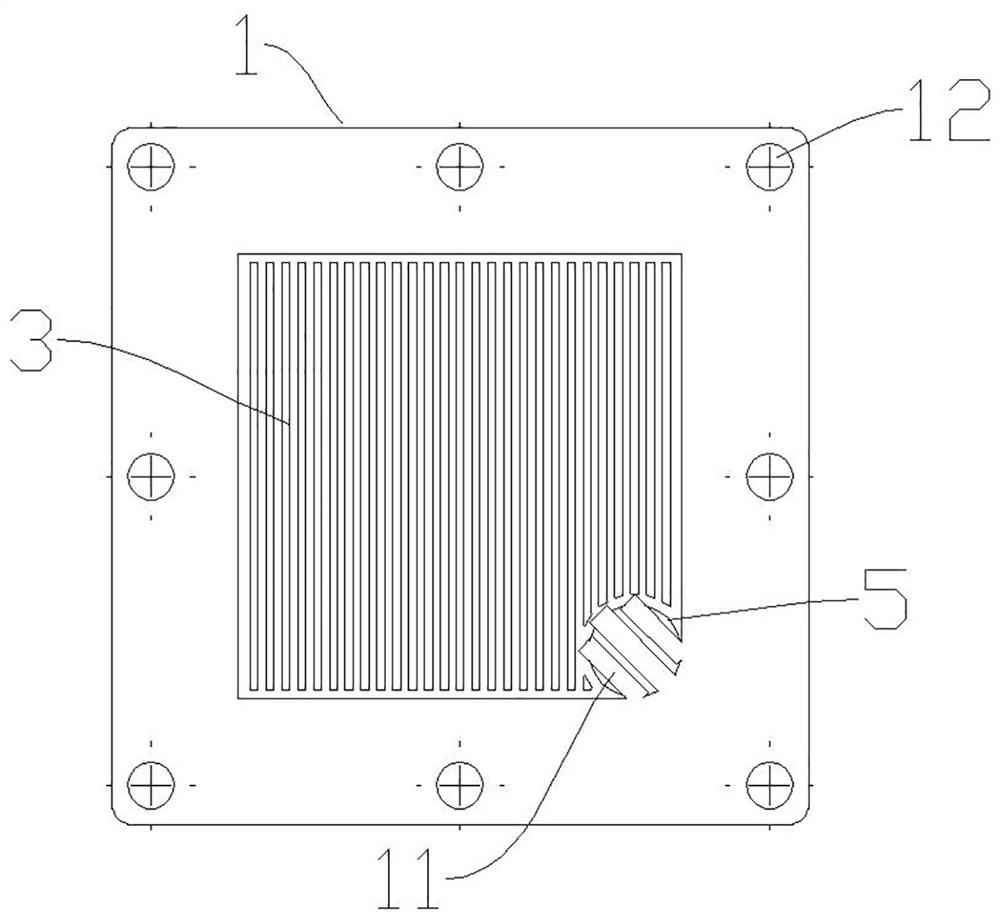

[0032] A new type of chemical hydrogen production reactor, such as Figure 1-2 As shown, it includes a first end plate 1, a second end plate 2, and a catalytic component disposed between the first end plate 1 and the second end plate 2; the first end plate 1 is attached to the catalytic component A first flow channel 3 is provided on one side surface of the joint, and a second flow channel 4 is provided on the side surface where the second end plate 2 is attached to the catalytic component, the first flow channel 3 and the second flow channel 4 Are the same parallel flow channels (such as image 3 Shown); The first end plate 1 is provided with a liquid inlet 5 communicating with the first flow passage 3, and the second end plate 2 is provided with a gas outlet communicating with the second flow passage 4 through 6; The liquid inlet holes 5 and the air outlet holes 6 are distributed diagonally, and the liquid inlet holes 5 are on the bottom and the air outlet holes 6 are on the t...

Embodiment 2

[0035] A new type of chemical hydrogen production reactor, the basic structure is the same as that of embodiment 1, the difference is: in this embodiment, the catalytic layer 7 is embedded in a piece of sealing element 8, and the catalytic layer 7 is directly fixed to The sealing element 8 and the hollow area of the sealing element 8 can also be embedded in the multilayer catalytic layer 7 as long as it does not exceed the upper and lower surfaces of the sealing element 8.

Embodiment 3

[0037] A new type of chemical hydrogen production reactor. The basic structure is the same as that of Embodiment 1. The difference is that: in this embodiment, there are three catalytic components, which are aligned and stacked between the first end plate 1 and the second end plate 2 during installation. Replace the long screw and lock the seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com