A kind of production equipment of environment-friendly water-soluble chalk

A production equipment and water-soluble technology, applied in the field of environmentally friendly water-soluble chalk production equipment, can solve the problems of cumbersome use process, time-consuming and laborious production process, waste of production resources, etc., and achieve the effects of preventing precipitation and condensation, reducing residual amount and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

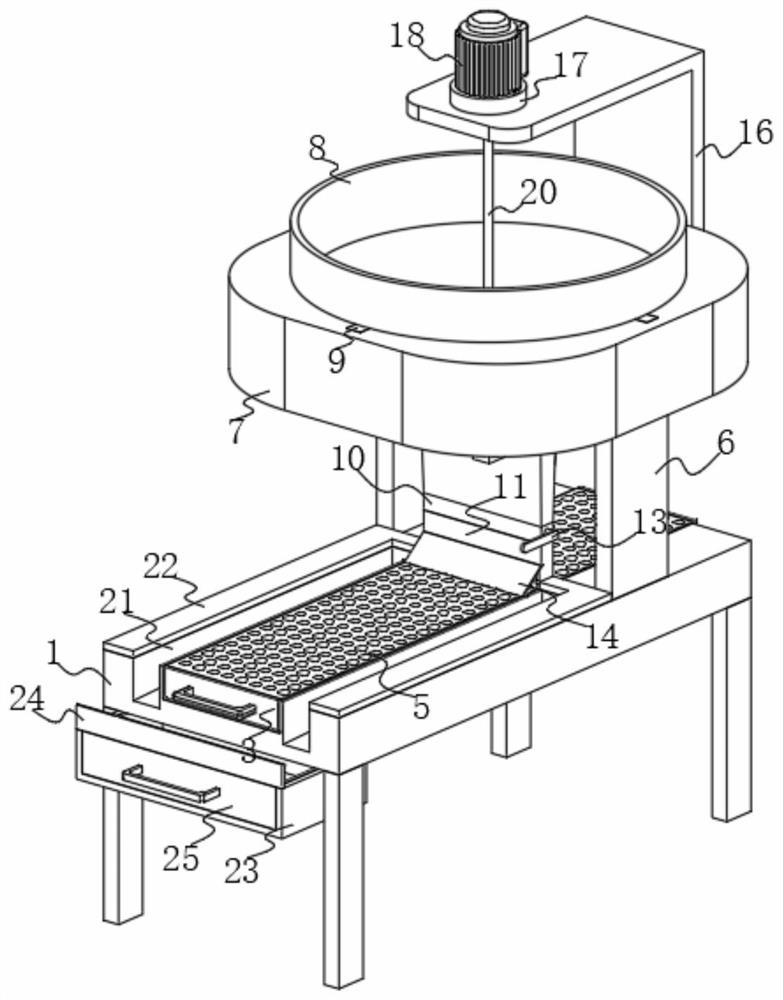

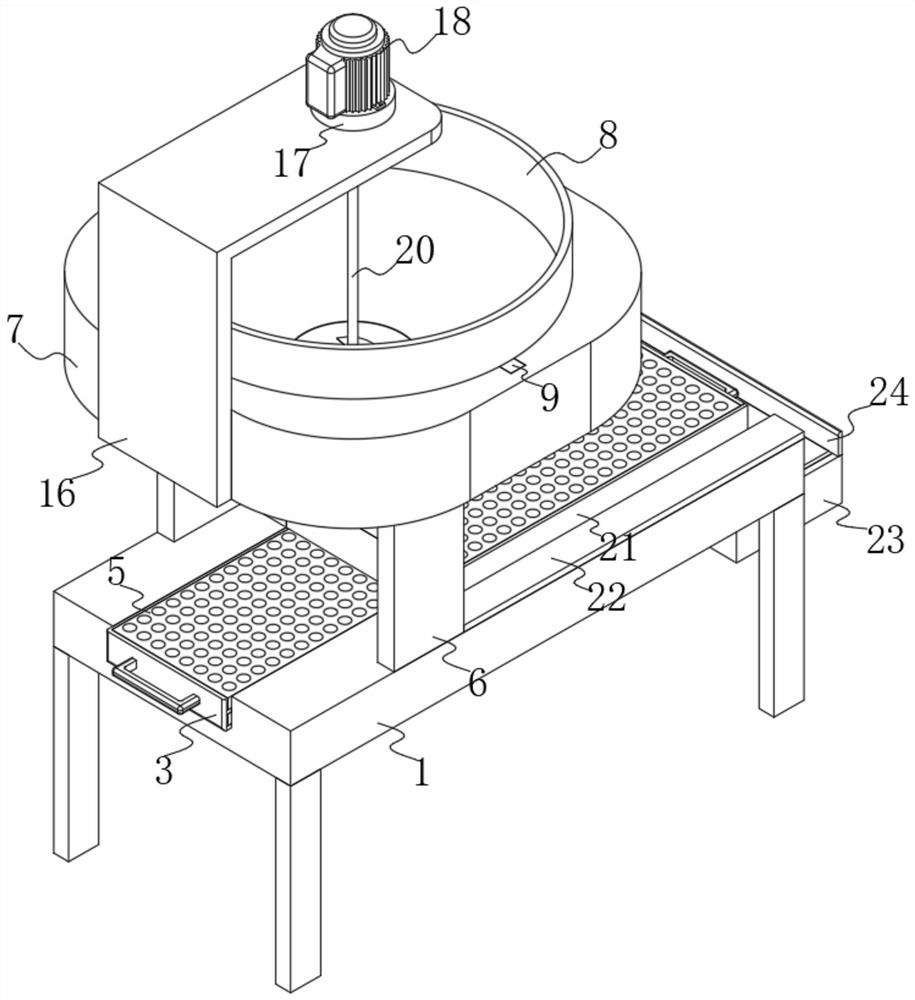

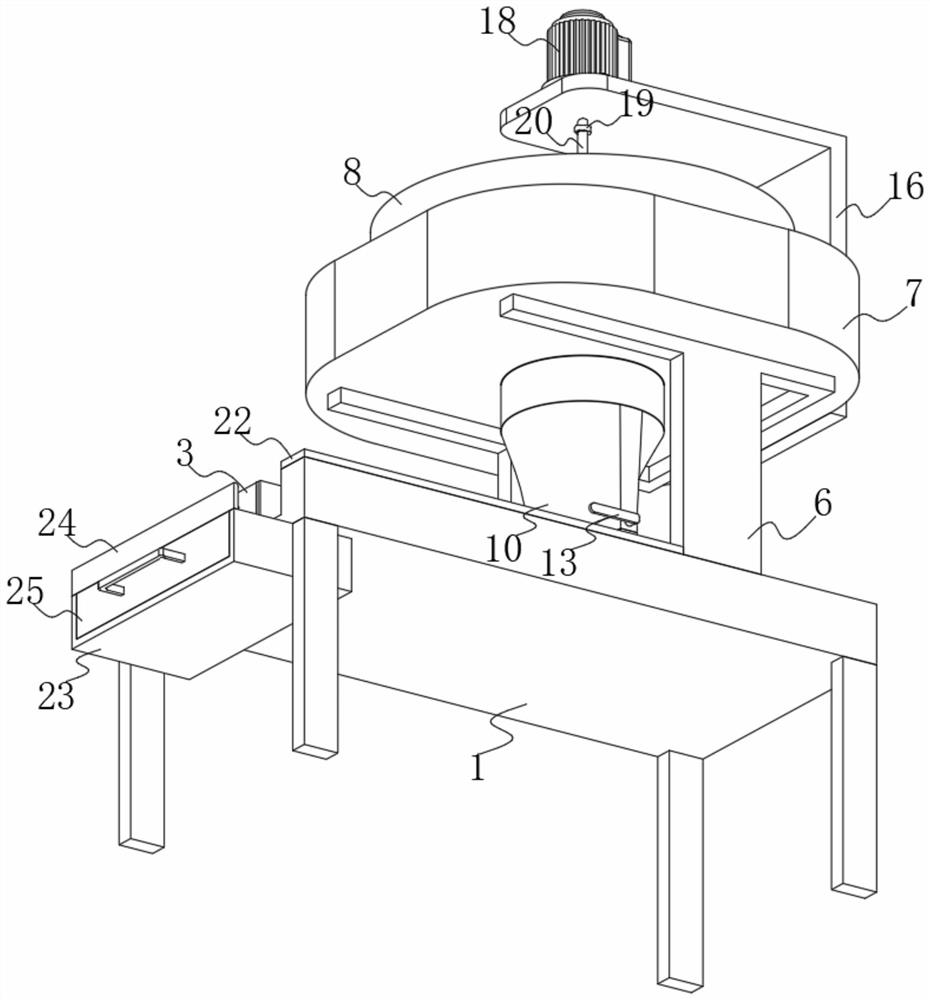

[0029] Embodiment one, with reference to Figure 1-11: An environment-friendly water-soluble chalk production equipment, including a filling table 1 and a filling device 26, the setting of the filling table 1 provides the installation basis for other functional parts of the equipment, and the setting of the filling device 26 enables the production raw materials to be effectively injected into the inside of the through hole for molding, Then the equipment can effectively carry out the production and manufacture of water-soluble chalk. The center of the top of the filling table 1 is provided with a chute 2 along the horizontal direction. Walking through, the sliding frame 3 is embedded inside the chute 2. The setting of the moving frame 3 facilitates the movement and transportation of the filling plate 5. At the same time, the filling plate 5 can effectively store the production raw materials, so that the equipment can perform its due functions normally. The realization of the m...

Embodiment 2

[0030] Embodiment two, refer to Figure 1-8 : The top of the filling table 1 is located at the center and a support frame 6 is welded on one side. The establishment of the support frame 6 facilitates the installation and setting of other functional parts of the equipment. 8, the center of the top of the installation frame 7 is provided with an installation groove, the installation groove is set up to effectively limit the use position of the mixing frame 8, and the inside of the installation groove is embedded with a mixing frame 8, the establishment of the mixing frame 8 is convenient for more The storage of production raw materials, so that the equipment can conveniently realize the due functions. The outer surface of the mixing frame 8 is located inside the installation groove and is welded with a positioning block 9. The establishment of the positioning block 9 effectively prevents the mixing frame 8 from being used during actual use. The offset of the position will furthe...

Embodiment 3

[0031] Embodiment three, refer to Figure 1-8 : The top of filling table 1 is welded with L-shaped anti-seepage blocks 22 at the two corners far away from support frame 6. The establishment of L-shaped anti-seepage blocks 22 can effectively prevent surplus production raw materials from overflowing filling table 1, and the bottom of filling table 1 is close to the L-shaped One side edge of anti-seepage block 22 is welded with storage frame 23, and the setting up of storage frame 23 is convenient to carry out the installation of storage drawer 25 and support plate 24 and is arranged, and storage frame 23 is a hollow straight square prism structure, and this The establishment of the structure enables the equipment to normally carry out due functions, and the top of the storage frame 23 and the outer surface of the side away from the filling table 1 are open structures. The establishment of this structure is convenient for the installation of the storage drawer 25. A storage drawe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com