Technique for preparing whole fish jelly of crucian

A process method, fish jelly technology, which is applied in the field of crucian carp whole fish jelly preparation, can solve the problems of shortening the storage time, shortening the shelf life of eating, easy corruption and deterioration, etc., and achieves the effects of prolonged storage time, high elasticity and moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

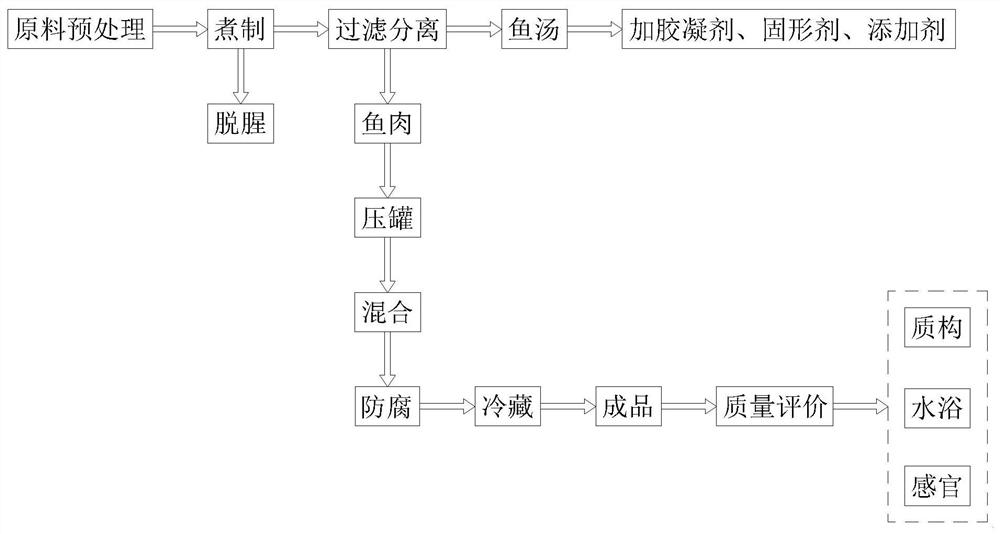

[0046] see Figure 1-7 A process for preparing crucian carp whole fish jelly, it comprises the following steps:

[0047] S1, raw material pretreatment, take crucian carp, remove fish scales, gills and viscera, wash with clean water, obtain spare raw material fish, and freeze it;

[0048] S2, cooking, adding water to the raw fish obtained in S1 according to the ratio of feed to liquid concentration of 1:6, then adding fresh condiments, seasonings, and spices for deodorization treatment, and cooking at 80°C for 1.5 hours;

[0049] S3, filtering and separating, performing filtering and separating operations on the cooked raw fish in S2 to obtain fish meat and fish soup;

[0050] S4, preparation, take the fish soup obtained in S3, after cooling to a suitable temperature, add a gelling agent, a solid agent and additives, and mix well to obtain a fish jelly stock solution;

[0051] S5, pressing the tank, filling the fish meat obtained in S3 into a cup-shaped container, and compact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com