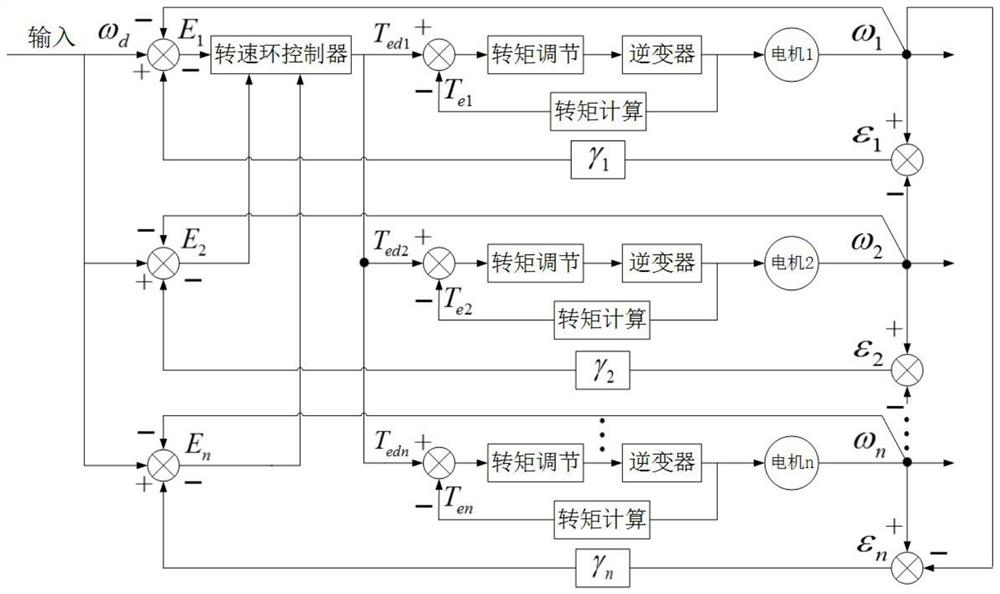

High-performance cooperative control method for multi-motor system based on sliding mode variable structure

A sliding mode variable structure and cooperative control technology, which is applied in multiple motor speed/torque control, motor generator control, electronic commutation motor control, etc. The effect of response characteristics, high reliability, and strong synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

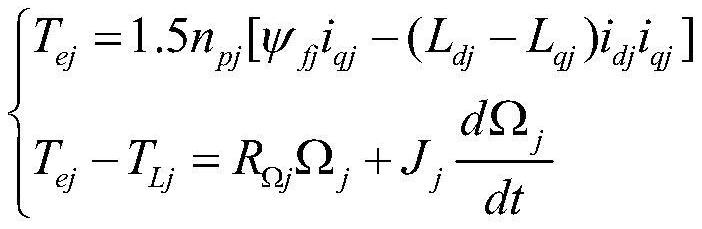

Method used

Image

Examples

Embodiment 2

[0116] The other content of this embodiment is the same as that of Embodiment 1, except that in order to effectively reduce the chattering problem caused by the control system, the continuous function to replace the function sgn(s j ), where δ takes a smaller normal number.

[0117] The multi-motor system high-performance cooperative control method based on the sliding mode variable structure proposed by the present invention effectively overcomes the problems of multi-variable, strong coupling and time-varying physical parameters in the multi-motor synchronous control system, making the system have faster dynamic response characteristics , high reliability and strong synergistic ability, well realize that each motor of the system can meet the complex working condition requirements of full-time synchronization of torque and speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com