Mounting method of fabricated arc-shaped power cable bracket

An installation method and technology for power cables, which are applied in the installation of cables, cable installation devices, electrical components, etc., can solve the problems of small internal space of circular pipes, increased labor usage, and inconvenient operation organization, so as to reduce labor, The effect of optimizing installation steps and speeding up transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

[0031] The present invention will be further described below in conjunction with the accompanying drawings and the processes of positioning, transporting, assembling and installing the bracket.

[0032] Construction process:

[0033] Embedded nuts for pipelines → building a transfer platform → assembly and transportation of circular arc columns → positioning → column installation → cross-arm transportation → cross-arm installation → overall review and acceptance.

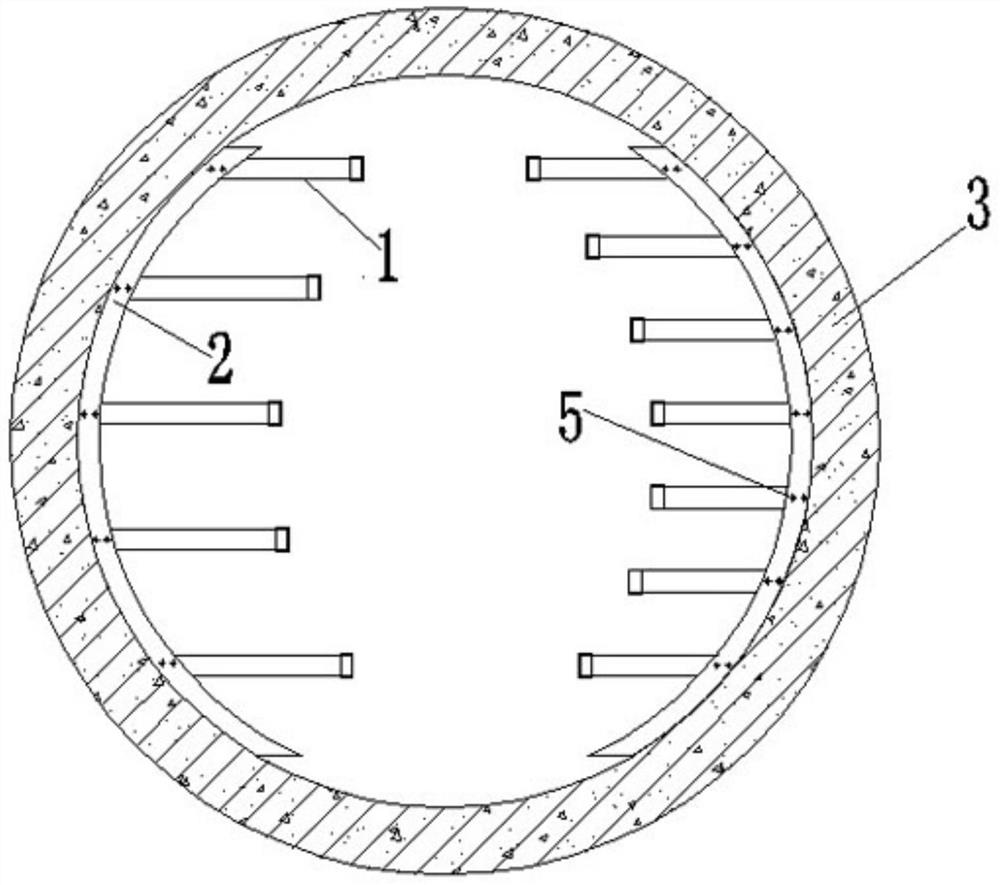

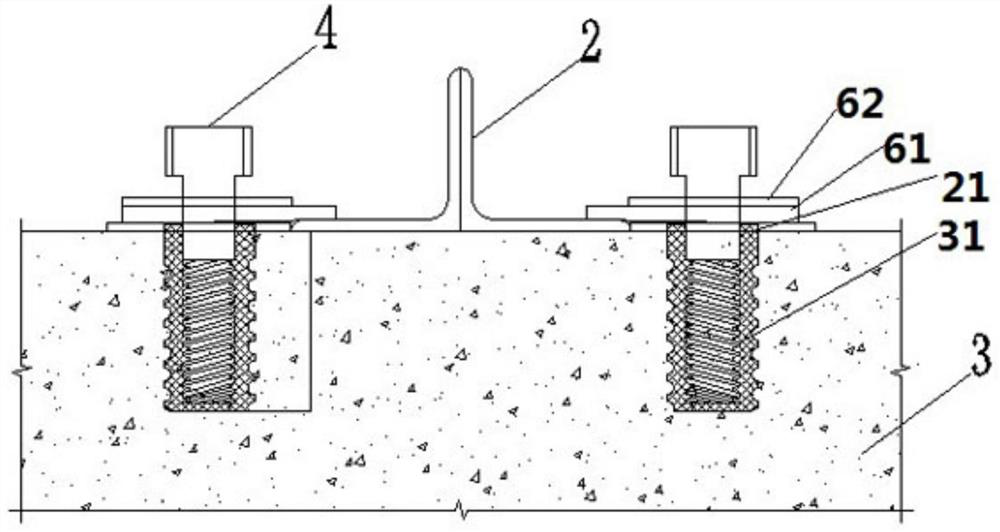

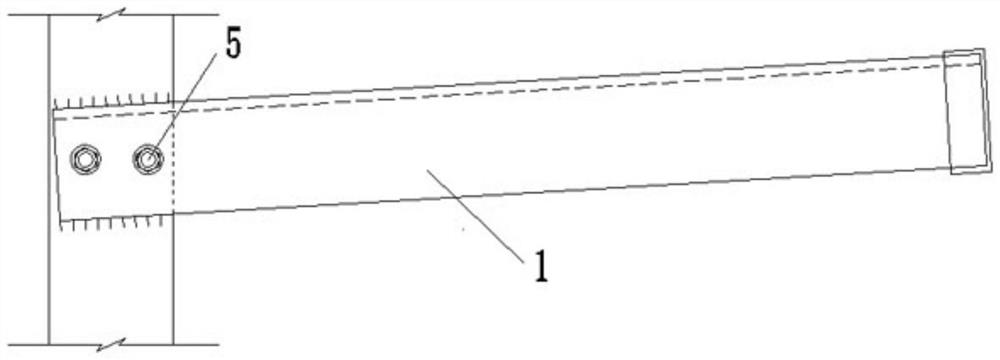

[0034] see Figure 1-3 The installation method of an assembled arc-shaped power cable bracket shown includes the following steps:

[0035] (1) Pipe nut pre-embedded:

[0036] According to engineering needs, a pre-embedded casing 31 is installed inside the concrete pipe 3, and high-strength nuts are used for the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com