Liquid discharging device, filtering system and semiconductor processing equipment

A technology of drainage device and filtration system, applied in semiconductor/solid-state device manufacturing, filtration separation, fixed filter element filter, etc., can solve the problem that the reactant cannot be effectively removed, there is no fixed flow direction, and the reactant cannot effectively enter the circulating filtration system problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

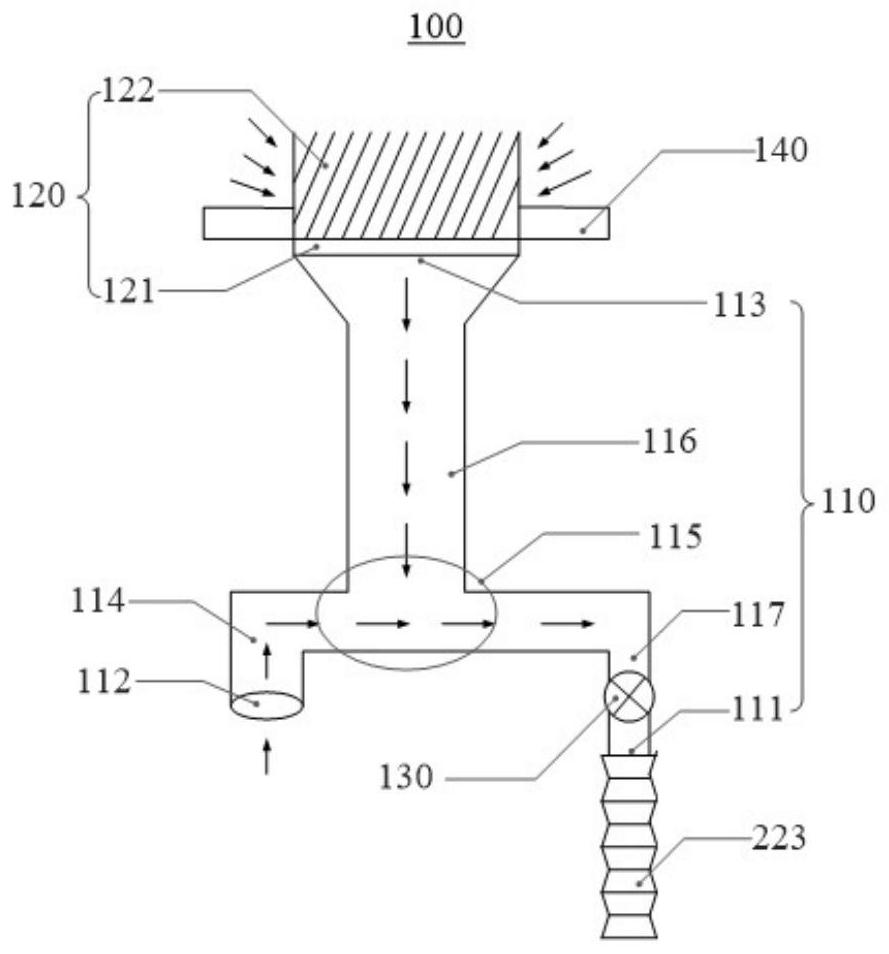

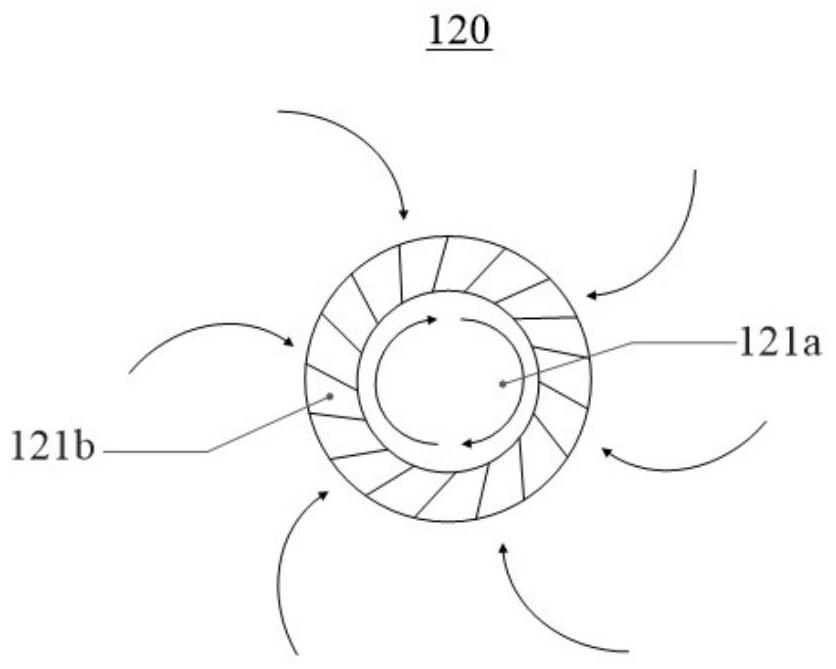

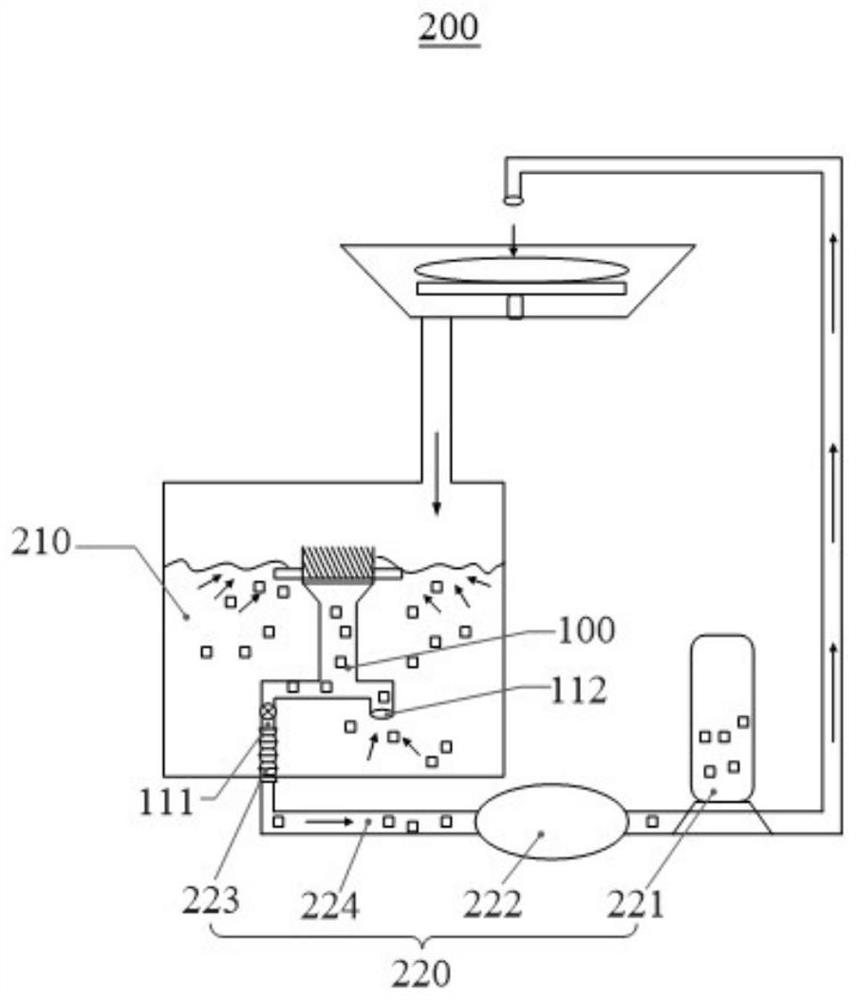

[0032] Such as figure 1 As shown, one aspect of the present invention provides a liquid discharge device 100, the liquid discharge device 100 includes a siphon 110 and a guide pipe 120, the siphon 110 is provided with a liquid outlet 111, a first liquid inlet 112 and a first The second liquid inlet 113 that the liquid inlet 112 communicates with the liquid outlet 111, the guide tube 120 communicates with the second liquid inlet 113, wherein, when the liquid outlet 111 is subjected to suction force, the first liquid inlet 112 and the second liquid inlet 113 are connected. A pressure difference is formed between the second liquid inlets 113 to form a siphon force at the second liquid inlet 113, and the guide pipe 120 guides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com