Centralized dissolving furnace waste gas treatment system for filter shell machining

A technology for waste gas treatment and dissolution furnace, applied in waste heat treatment, furnace, furnace components, etc., can solve the problems of waste gas treatment, gas human harm, air pollution, etc., to save operating costs, ensure absorption, and safe working environment. Effect

Inactive Publication Date: 2020-09-01

江苏日研精工智能制造有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the deficiencies of the prior art, the present invention provides a centralized melting furnace exhaust gas treatment system for filter shell processing, which solves the problem that the existing open or semi-closed melting furnaces cannot process the exhaust gas generated. If a large amount of processing is concentrated Directly discharge polluted air, and some gases in the exhaust gas will cause harm to the human body. At the same time, when facing the recycling of raw materials, the situation is even more serious.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0028] Implementation 2, when it is used in an electric heating furnace, it can be operated directly according to the use.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

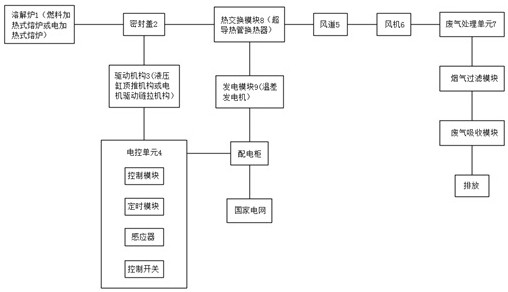

The invention discloses a centralized dissolving furnace waste gas treatment system for filter shell machining. The system comprises a dissolving furnace, wherein a sealing cover is arranged at a feeding port of the dissolving furnace and fixedly connected with the dissolving furnace through a driving mechanism, the exterior of the driving mechanism communicates with an electric control unit, theouter side of the sealing cover communicates with an air duct, the tail end of the air duct communicates with a draught fan, an air outlet of the draught fan communicates with a waste gas treatment unit, the front side of the air duct communicates with a heat exchange module, and a power generation module is arranged on the outer side of the heat exchange module. According to the centralized dissolving furnace waste gas treatment system for filter shell machining, the problems that waste gas generated by an existing open or semi-closed dissolving furnace cannot be treated, polluted air is directly discharged when a large amount of waste gas is treated in a centralized mode, part of gas in the waste gas can harm the human body, and meanwhile the situation is more serious when raw materialsare recycled are solved.

Description

technical field [0001] The invention relates to the technical field of waste gas treatment, in particular to a centralized dissolution furnace waste gas treatment system for filter shell processing. Background technique [0002] The power filter is a filter circuit composed of capacitors, inductors and resistors. The filter can effectively filter out the frequency points of a specific frequency in the power line or frequencies other than this frequency point, obtain a power signal of a specific frequency, or eliminate a For the power signal after a specific frequency, in order to protect the internal components, the circuit components are fixed in the housing. At present, the filter housing is mainly made of high-strength plastic, aluminum, aluminum alloy, stainless steel and other materials, but it needs to be used during production. The raw material is dissolved in a furnace, and then cast into a mold. The existing melting furnace is generally open or semi-closed, and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27D17/00F27D1/18

CPCF27D1/1808F27D17/004F27D17/008

Inventor 杨国章

Owner 江苏日研精工智能制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com