A Modular Gearbox Electric Oil Pump

An electric oil pump and gearbox technology, applied in the field of electric oil pumps for modular gearboxes, can solve problems affecting the smooth operation of bearing shaft teeth, impact on motor performance, early wear of bearing friction pairs, etc., to facilitate installation and layout, and facilitate rapid assembly , The effect of simplifying the layout structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

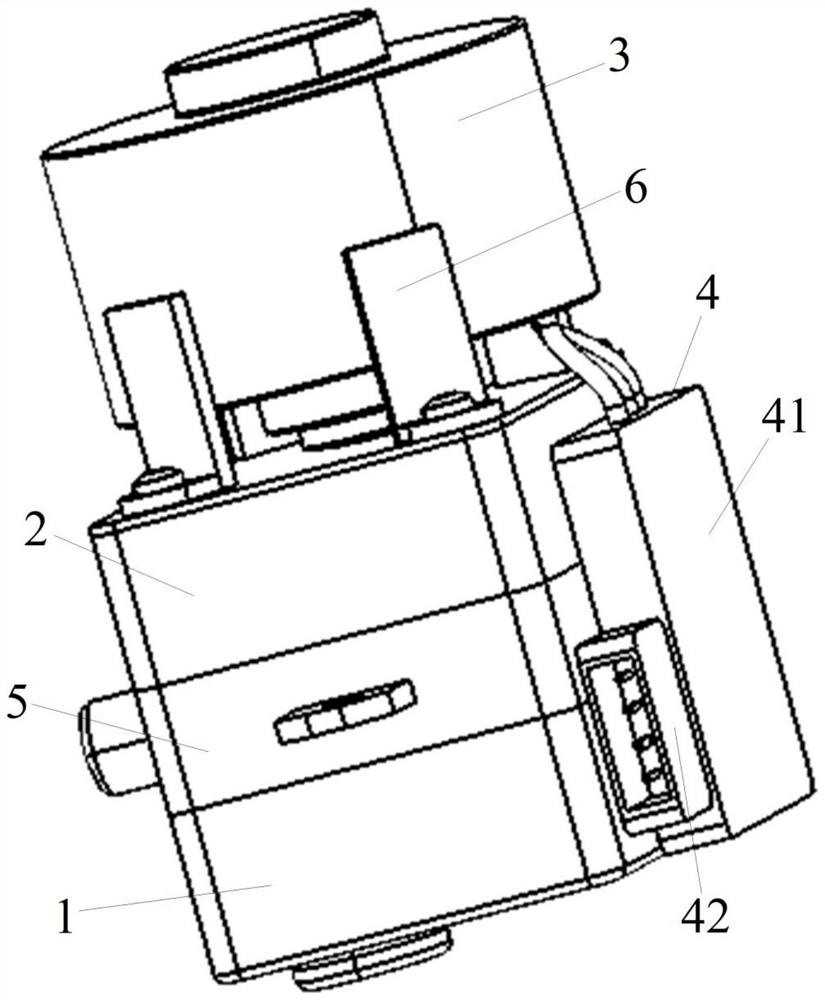

[0052] Such as Figure 1-15 As shown, the oil pump in this embodiment is a highly integrated modular structure used in gearboxes, including an integrated filter module 1, an oil pump module 2, a motor module 3 and a control module 4, and the filter module 1 is used for Filter the oil to prevent impurities from entering subsequent equipment and cause adverse effects. The oil pump module 2 drives the oil to flow in the pipeline system, the motor module 3 drives the oil pump module 2 to run, and the control module 4 is responsible for controlling the operation of the motor module 3 .

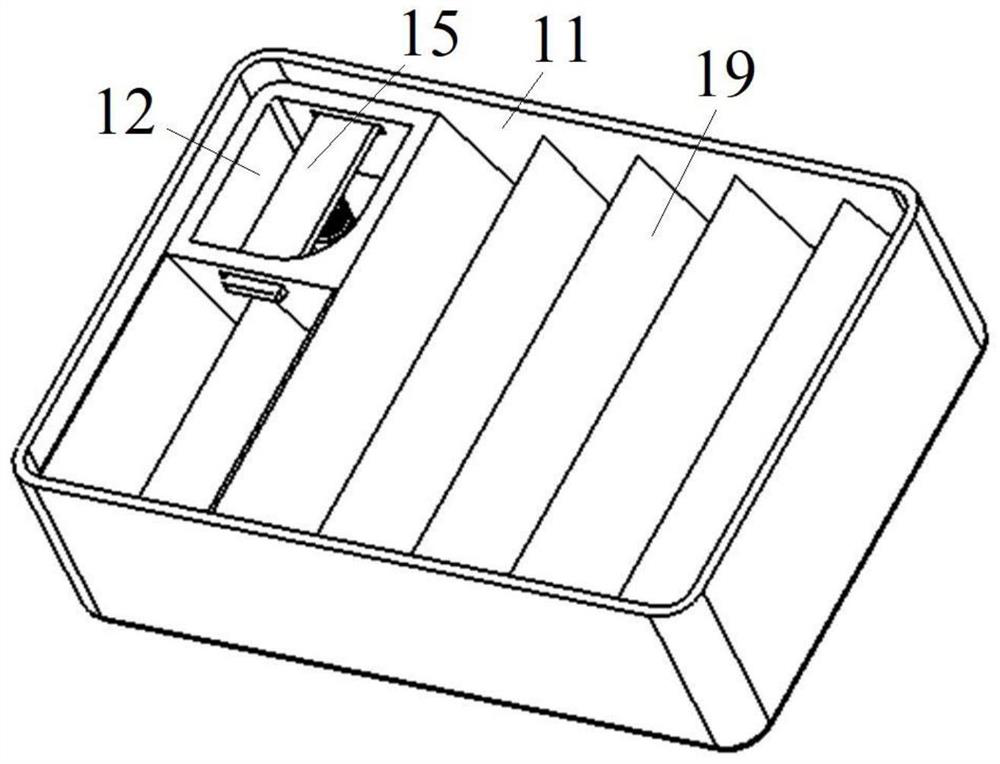

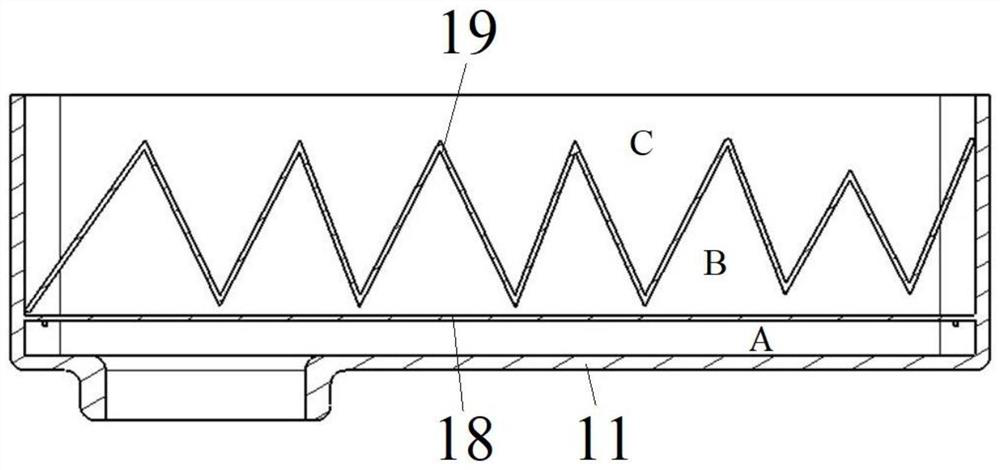

[0053] Such as Figure 2-5 As shown, it is a structural schematic diagram of the filter module 2 of this embodiment. The filter module 2 includes a filter cover plate 11. The filter cover plate 11 is a hollow box structure. Two filter structures are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com