Liquid suction and drainage valve and working method thereof

A liquid discharge valve and liquid suction valve technology, applied in the field of liquid suction and discharge valves, can solve the problems of many types of parts and styles, difficult installation and maintenance, and large inventory of spare parts, and achieve the effects of compact structure, reduced cavitation, and simple guiding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

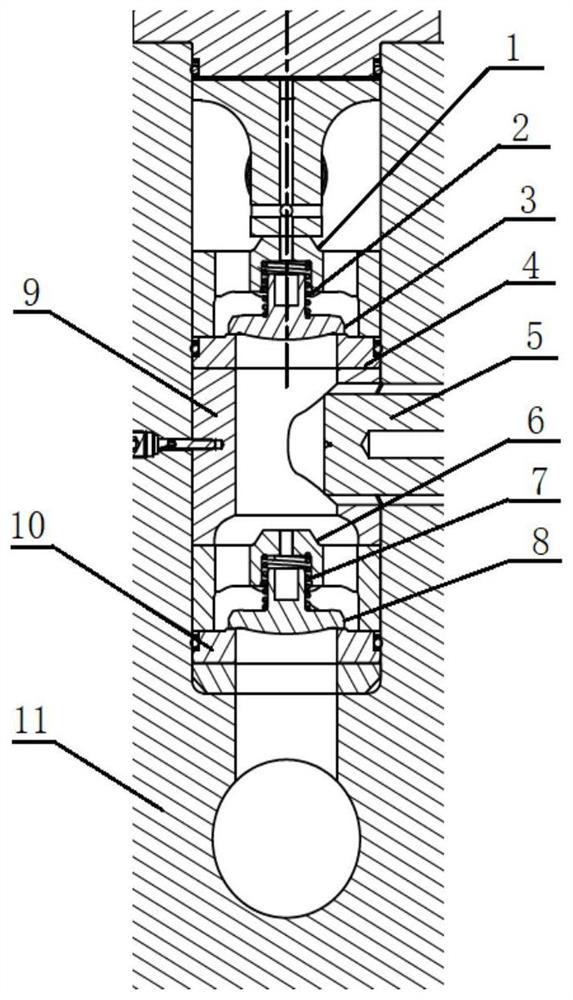

[0022] The invention provides a liquid suction and discharge valve, which is used to realize the functions of a plunger pump used in a pumping station that supplies a power source to a coal mine hydraulic support to suck in and discharge media such as water or emulsion, including: a liquid discharge valve guide seat 1, a liquid discharge valve Valve spring 2, discharge valve core 3, discharge valve seat 4, plunger 5, suction valve guide seat 6, suction valve spring 7, suction valve core 8, sleeve 9, suction valve seat 10 and pump Head shell 11;

[0023] The drain valve guide seat 1 is used to guide the movement of the drain valve core 3; the drain valve spring 2 is used to automatically reset the drain valve core 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com