Flame-retardant ultralow-heat-conductivity-coefficient PFU foam and manufacturing method thereof

A technology of thermal conductivity and foam, which is applied in the field of thermal insulation foam, can solve the problems of easily corroded metal objects, etc., and achieve the effect of good mechanical properties, good compatibilizer, and slow aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

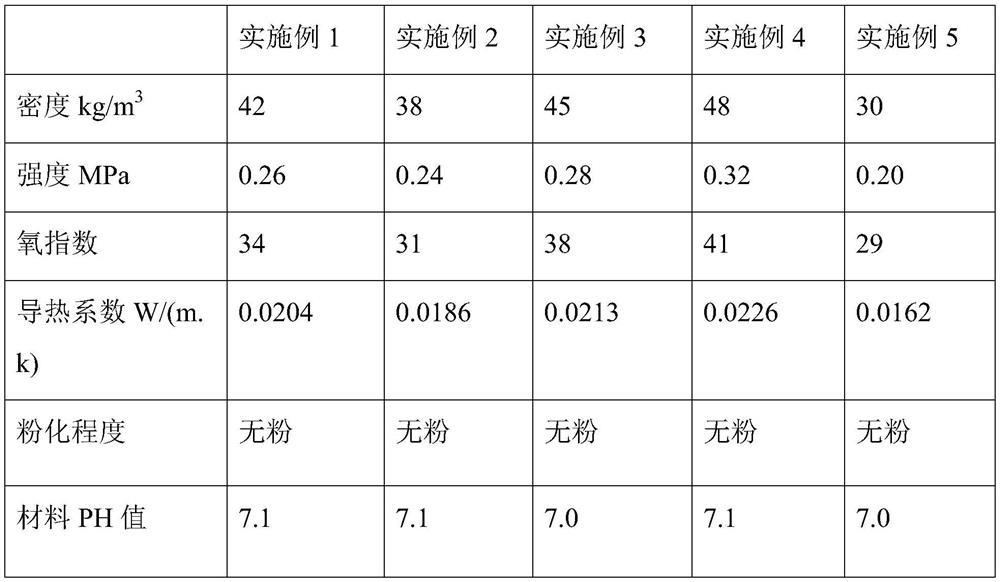

Examples

Embodiment 1

[0028] A method for making a flame-retardant ultra-low thermal conductivity PFU foam, using the following steps:

[0029](1) Prepare materials according to the following components and parts by weight: 100 parts of PFU resin, 2.5 parts of foam stabilizer, 0.5 parts of catalyst, 18 parts of modifier, 14 parts of blowing agent, and 145 parts of isocyanate. The agent is Tween-80, the flame retardant is TCPP, the catalyst is T12, the modifier is a mixed solution of diisopropanolamine and polyethylene glycol 200 at a ratio of 1:8, and the foaming agent is pentane;

[0030] (2) Put the total amount of PFU resin, foam stabilizer, catalyst, modifier, and blowing agent into the mixing tank according to the formula, and then stir for 20-50min until uniform;

[0031] (3) Mix the above-mentioned (2) components with isocyanate, stir evenly at a high speed and inject into the mold;

[0032] (4) The above-mentioned (3) mold is foamed and cured at a temperature of 55--65° C. to obtain a flam...

Embodiment 2

[0035] A method for making a flame-retardant ultra-low thermal conductivity PFU foam, using the following steps:

[0036] (1) Prepare materials according to the following components and parts by weight: 100 parts of PFU resin, 3.2 parts of foam stabilizer, 0.8 parts of catalyst, 15 parts of modifier, 18 parts of foaming agent, and 140 parts of isocyanate. The agent is a mixture of AK8801 and AK8806, the flame retardant is TECP, the catalyst is T12, the modifier is a mixed solution of diisopropanolamine and polyethylene glycol 200 at a ratio of 1:6, and the blowing agent is cyclopentane;

[0037] (2) Put the total amount of PFU resin, foam stabilizer, catalyst, modifier, and blowing agent into the mixing tank according to the formula, and then stir for 20-50min until uniform;

[0038] (3) Mix the above-mentioned (2) components with isocyanate, stir evenly at a high speed and inject into the mold;

[0039] (4) The above-mentioned (3) mold is foamed and cured at a temperature of...

Embodiment 3

[0042] A method for making a flame-retardant ultra-low thermal conductivity PFU foam, using the following steps:

[0043] (1) Prepare materials according to the following components and parts by weight: 100 parts of PFU resin, 4 parts of foam stabilizer, 1.0 parts of catalyst, 20 parts of modifier, 12 parts of foaming agent, and 165 parts of isocyanate. The agent is a mixture of Tween 80 and AK8806, the flame retardant is a mixture of TECP and aluminum hydroxide, the catalyst is an organotin substance, and the modifier is a mixture of diisopropanolamine and polyethylene glycol 200 at a ratio of 1:5. The solution and foaming agent are mixed pentane;

[0044] (2) Put the total amount of PFU resin, foam stabilizer, catalyst, modifier, and blowing agent into the mixing tank according to the formula, and then stir for 20-50min until uniform;

[0045] (3) Mix the above-mentioned (2) components with isocyanate, stir evenly at a high speed and inject into the mold;

[0046] (4) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com