Novel rectilinear reciprocating type and high-efficiency intelligent environment-friendly type unloader with continuous chain buckets

A reciprocating, environmentally friendly technology, applied in loading/unloading, transportation and packaging, etc., can solve the problems of parts damage and clearance, low production efficiency, large space occupation, etc., and achieve the effect of less return material, high productivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

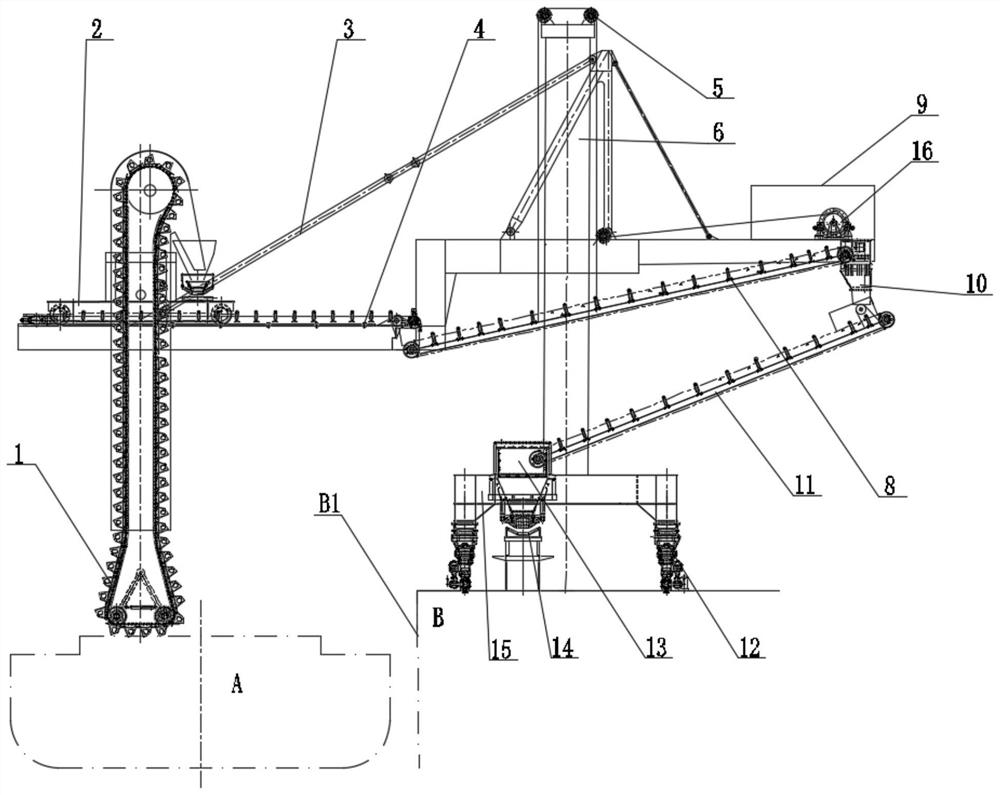

[0038] like figure 1 and figure 2As shown, the new linear reciprocating high-efficiency intelligent environment-friendly continuous chain bucket ship unloader of this embodiment includes a chain bucket retrieving mechanism 1, and the chain bucket retrieving mechanism 1 is fixed on the trolley assembly 2, and is connected with the trolley assembly 2. Move horizontally along the boom mechanism 3, the boom mechanism 3 is equipped with the boom belt 4 connected to the discharge port of the chain bucket reclaiming mechanism 1, the transfer belt 8 docked with the boom belt 4, and the output end of the transfer belt 8 The transfer hopper 10 is docked with the discharge belt 11, and the output end of the discharge belt 11 is docked with the dock belt conveyor 14 arranged on the dock B through the central hopper 13; it also includes a cart travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com