Belt storage device of underground coal mine bet conveyor

A belt conveyor and belt storage technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems that the functions and advantages of the belt storage device cannot be brought into play, increase the labor intensity of miners and the number of workers, and the maintenance and maintenance are cumbersome. , to achieve the effect of easy handling and maintenance, light weight and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

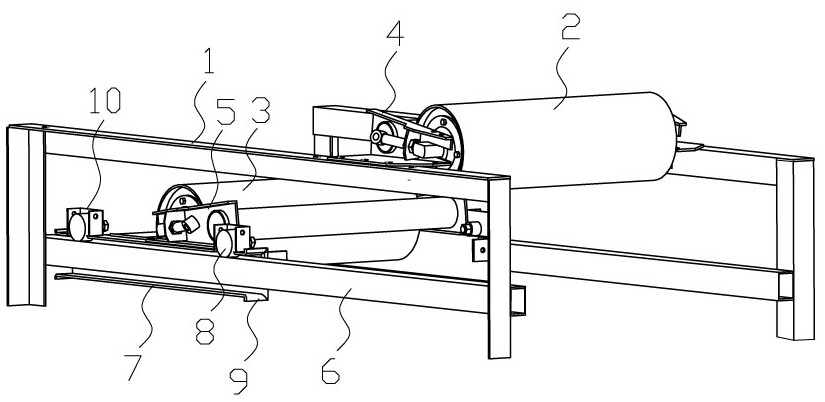

[0012] Such as figure 1 As shown, the belt storage device of an underground belt conveyor in a coal mine includes a belt storage device frame 1, a front reversing roller 2 and a tensioning roller 3, and the front reversing roller 2 is fixed on the belt storage device frame 1 through a roller frame 4. The tensioning roller 3 is movably connected with the belt storage device frame 1 through the tension trolley frame 5, so that the tensioning roller 3 can move back and forth on the belt storage device frame 1, and the said belt storage device frame 1 is provided with two longitudinal side rails 6. Both sides of the tensioning trolley frame 5 are respectively provided with a groove 7 for matching with the longitudinal side rail 6, and the groove 7 is stuck on the longitudinal side rail 6, so that the tensioning trolley frame 5 can only The side rail 6 moves back and forth, and the top surface of the groove 7 is respectively opened near the front and rear ends, and a roller 8 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com