Efficient automatic soldering process for patch common-mode inductors

A common mode inductor and patch technology, applied in the field of high-efficiency automated soldering process, can solve problems such as low efficiency, inability to guarantee quantitative control of flux, and unstable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

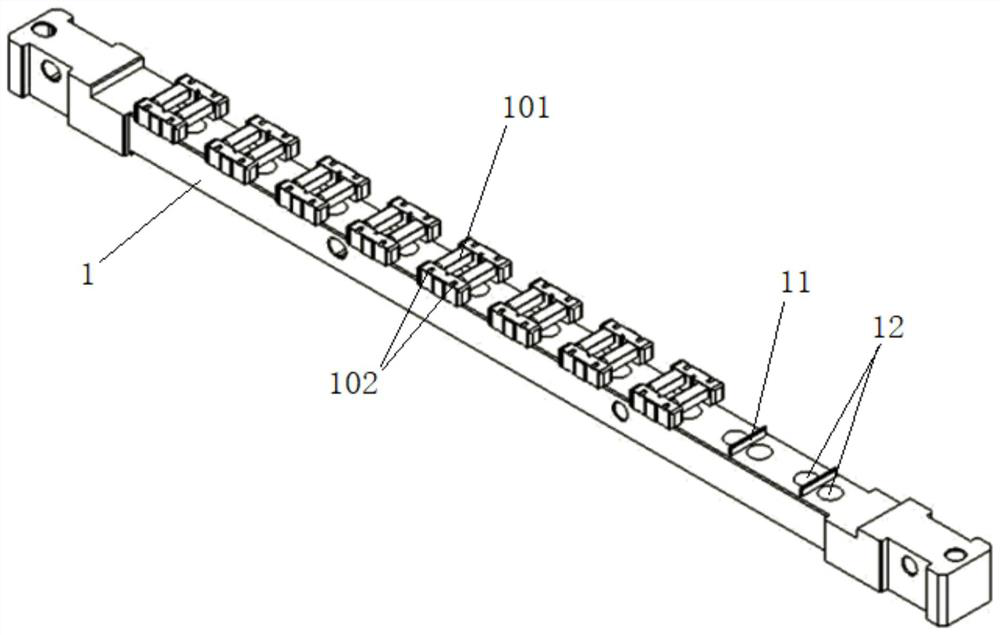

[0030] Please refer to Figure 1-Figure 2 , the present embodiment is a high-efficiency automated soldering process for chip common mode inductors, which includes the following steps:

[0031] 1) A jig bar 1 is provided, and the patch common-mode inductors 101 are placed on the jig bar 1 at intervals. The upper surface of the jig bar 1 is provided with a limiting protrusion inserted into the inside of the patch common-mode inductor 101 for positioning. Lifting 11, the adsorption magnetic block 12 located on both sides of the limit protrusion 11 and adsorbing the patch common mode inductor 101;

[0032] 2) Move the chip common mode inductor 101 loaded with the automatic conveying device to the flux spraying station; the automatic conveying device may be a linear conveying mechanism or a disc rotating conveying mechanism;

[0033] 3) The jig bar 1 is deflected clockwise around a horizontal line to set the angle, and the chip common mode inductor 101 arranged on the jig bar 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com