Preparation method of thick-paste-method reconstituted tobacco raw material special for heating cigarettes

A technology of reconstituted tobacco leaves and thick pulp method, which is applied in the fields of tobacco preparation, application, tobacco, etc. It can solve the problems of rising temperature of tobacco stems, difficult control of material temperature, loss of aroma substances and nicotine in tobacco leaves, etc., and achieve precise processing and regulation , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

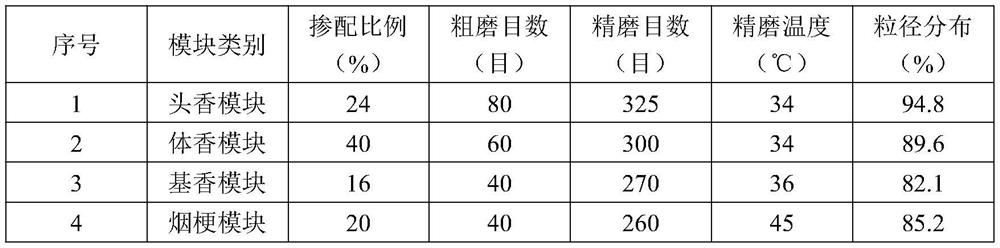

Embodiment 1

[0036] In order to show the superior effect of the present invention, it is proved by comparative experiments below.

[0037] (1) Prepare 200 kg of raw materials, which are equally divided into two parts A and B, each 100 kg, wherein the raw materials of tobacco slices and tobacco stems are 80 kg and 20 kg respectively.

[0038] (2) The sheet tobacco and tobacco stem raw materials in raw material A are pretreated and roughly ground separately, and then mixed, finely ground and buffered according to the proportion. Among them, the rough grinding mesh of tobacco stems and tobacco slices is 40 mesh and 60 mesh, the fine grinding particle size is 300 mesh, the fine grinding particle size distribution is D90, and the fine grinding temperature is within 45°C. Finally, the thick pulp reconstituted tobacco leaves were prepared according to the optimized process, wherein the thickness was 0.16mm±0.02mm, and the moisture content was 10%±1%.

[0039] (3) The sheet tobacco and tobacco stem...

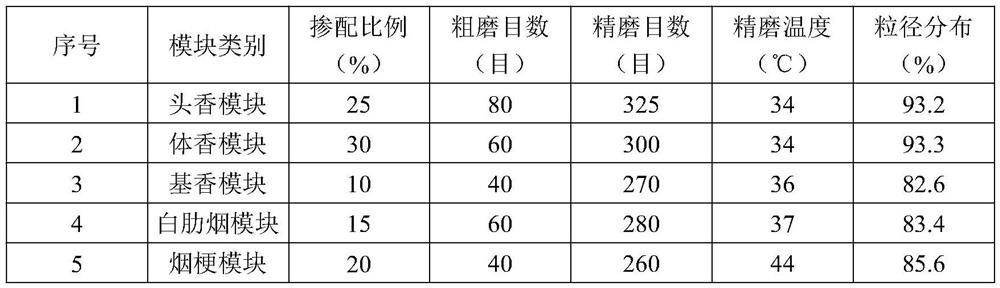

Embodiment 2

[0051] In order to improve the aroma and thickness of the reconstituted tobacco leaves by the thick pulp method, 15% of Burley tobacco flakes are added when the raw materials are assembled. specific method:

[0052] (1) Prepare 200 kg of raw materials, which are equally divided into two parts A and B, each 100 kg, wherein the raw materials of sheet tobacco and tobacco stem are respectively 80 kg (including 12 kg of Burley tobacco, with a total sugar content of 0.65% and a nicotine content of 4.87%) and 20kg.

[0053] (2) The sheet tobacco (including burley tobacco) and tobacco stem raw materials in raw material A are pretreated and roughly ground respectively, and then mixed, finely ground and buffered according to the proportion. Among them, the rough grinding mesh of tobacco stems and tobacco slices is 40 mesh and 60 mesh, the fine grinding particle size is 300 mesh, the fine grinding particle size distribution is D90, and the fine grinding temperature is within 45°C. Fina...

Embodiment 3

[0062] Add 5% functional plant material modules (2% black plum, 3% kudzu root) when assembling the raw materials to improve the taste. specific method:

[0063] (1) Prepare 200kg of raw materials, which are equally divided into two parts, A and B, each 100kg, of which tobacco flakes, tobacco stems and functional plant materials are 80kg, 15kg and 5kg respectively.

[0064] (2) Sheet tobacco, tobacco stem raw materials, and functional plant materials in raw material A are pretreated and roughly ground separately, and then mixed, finely ground, and buffered according to the proportion. Among them, the rough grinding mesh of tobacco stems and tobacco slices is 40 mesh and 60 mesh, the fine grinding particle size is 300 mesh, the fine grinding particle size distribution is D90, and the fine grinding temperature is within 45°C. Finally, the thick pulp reconstituted tobacco leaves were prepared according to the optimized process, wherein the thickness was 0.18mm±0.02mm, and the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com