Method for quickly evaluating the performance of tunnel hole slag suitable for preparing machine-made aggregate

An evaluation method and tunnel technology, applied in the field of building materials, can solve the problems of unsuitable tunnel slag parent rock compressive strength test, unable to evaluate the strength of parent rock, irregular shape of tunnel slag, etc. Operation, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

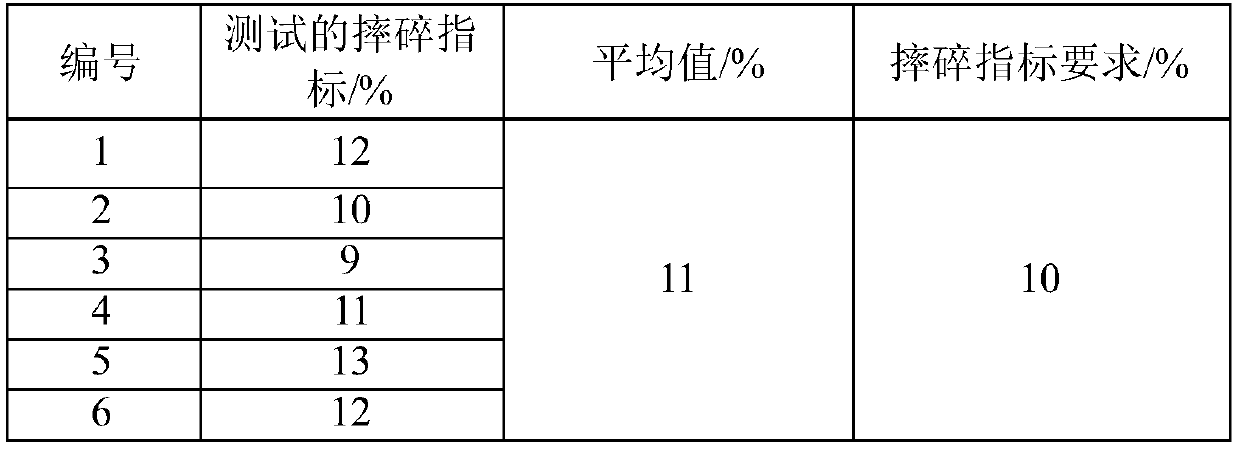

Embodiment 1

[0025] The test operation uses six randomly selected tunnel slag parent rocks as the research objects. The crushing index is used to characterize, including the following steps: 1) Sampling: Randomly select tunnel slag from different tunnel faces in the same section, and the shape of the tunnel slag is ellipsoid. 2) Transportation: Transport the tunnel slag to the test site by truck. 3) Test: Weigh the initial mass of the tunnel slag to be 5kg-10kg, drop the tunnel slag freely from 10m onto a solid iron platform, and then pass it through a sieve with an aperture of 4.75mm to remove particles smaller than sieve size particles and weigh the mass of the remaining tunnel dross. 4) Data processing and analysis: quickly evaluate the parent rock performance of tunnel slag with a potential energy in the range of 500J-1000J by calculating the crushing index, and the slag that meets the performance requirements can be quickly sorted out as raw materials for machine-made aggregates. Th...

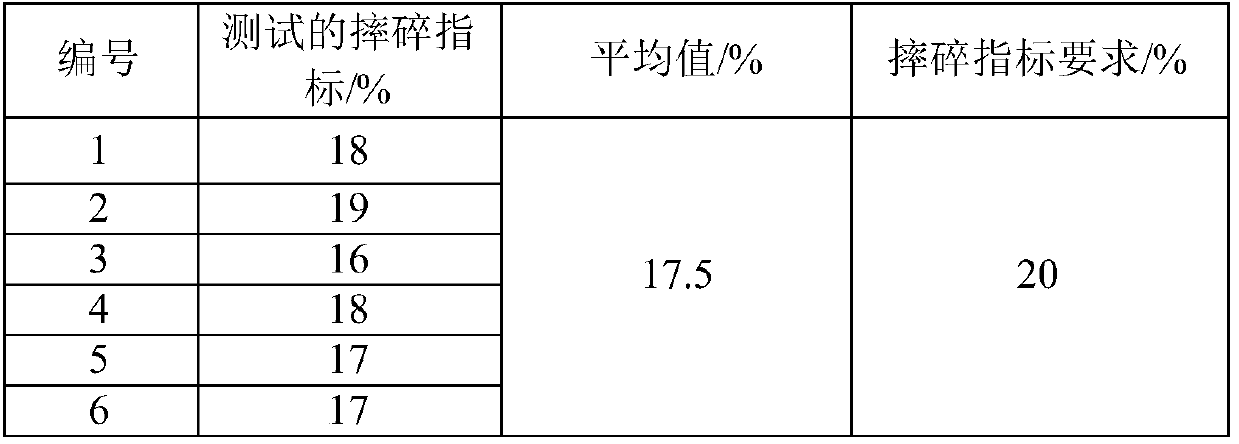

Embodiment 2

[0030] The test operation uses six randomly selected tunnel slag parent rocks as the research objects. The crushing index is used to characterize, including the following steps: 1) Sampling: Randomly select tunnel slag from different tunnel faces in the same section, and the shape of tunnel slag is all cuboid. 2) Transportation: Transport the tunnel slag to the test site by truck. 3) Test: Weigh the initial mass of the tunnel slag to be 15kg-25kg, drop the tunnel slag freely from 10m onto a solid iron platform, and then pass through a sieve with an aperture of 9.5mm to remove particles smaller than sieve size particles and weigh the mass of the remaining tunnel dross. 4) Data processing and analysis: quickly evaluate the performance of the parent rock of the tunnel slag with a potential energy in the range of 1500J-2500J by calculating the crushing index, and the slag that meets the performance requirements can be quickly sorted out as the raw material of the machine-made agg...

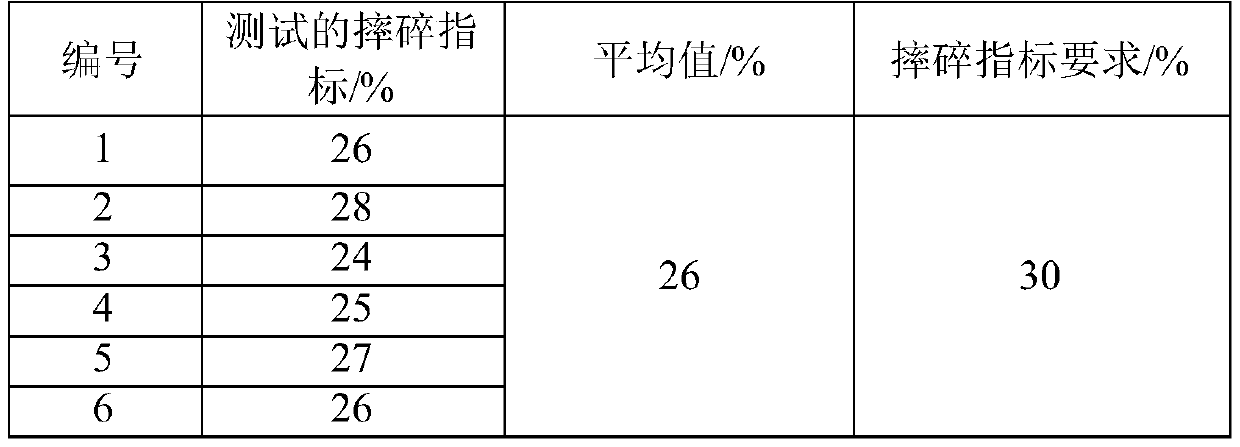

Embodiment 3

[0035] The test operation uses six randomly selected tunnel slag parent rocks as the research objects. The crushing index is used to characterize, including the following steps: 1) Sampling: Randomly select tunnel slag from different tunnel faces in the same section, and the shape of tunnel slag is all cuboid. 2) Transportation: Transport the tunnel slag to the test site by truck. 3) Test: Weigh the initial mass of the tunnel slag to be 30kg-50kg, drop the tunnel slag freely from 10m onto a solid iron platform, and then pass it through a sieve with an aperture of 19mm to remove particles smaller than the sieve. pore size particles and weigh the mass of the remaining tunnel slag. 4) Data processing and analysis: quickly evaluate the performance of the parent rock of the tunnel slag with a potential energy in the range of 3000J-5000J by calculating the crushing index, and the slag that meets the performance requirements can be quickly sorted out as the raw material of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com