Temperature measuring components for the process pipeline of the liquid oxygen kerosene engine test system

A technology of test system and process pipeline, applied in the field of temperature measurement components for process pipeline of liquid oxygen kerosene engine test system, can solve the problems of mismatched installation interface, low measurement accuracy, poor sealing performance, etc., and achieve high connection reliability , The effect of high measurement accuracy and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

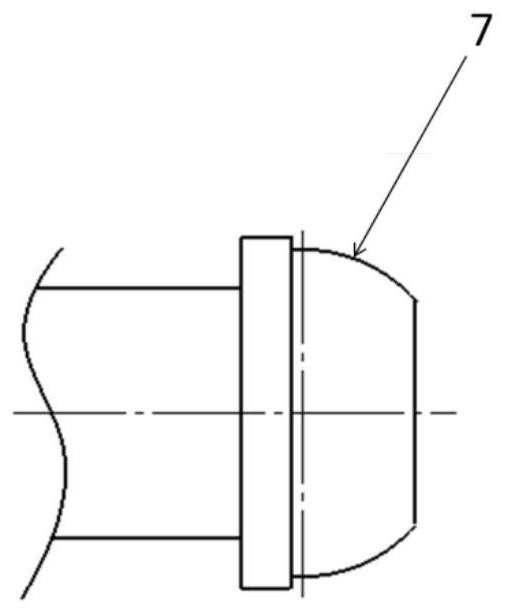

[0059] The present invention will be further described below in conjunction with accompanying drawing.

[0060] The liquid oxygen kerosene engine test system process pipeline temperature measurement assembly provided by the present invention, according to the engine test temperature measurement range, measurement uncertainty (ie accuracy requirements), temperature response time, design the structural form of the temperature measurement assembly, that is, according to the test Parameter measurement requirements, the type of temperature sensor designed armored temperature sensor. Such as Figure 1 to Figure 2 , Figure 4 to Figure 11 As shown, the temperature measurement assembly includes a platinum resistance temperature sensor and / or a thermistor temperature sensor installed on the pump front pipeline, a platinum resistance temperature sensor and / or a thermistor temperature sensor installed on the propellant supply pipeline, and a Thermocouple temperature sensor on evaporato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com