Double-thread nut and preparation process thereof

A preparation process, double-thread technology, applied in the direction of nuts, threaded fasteners, mechanical equipment, etc., to achieve the effect of convenient screw connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

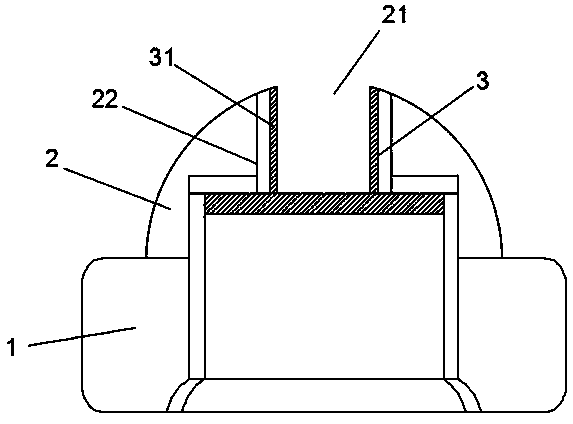

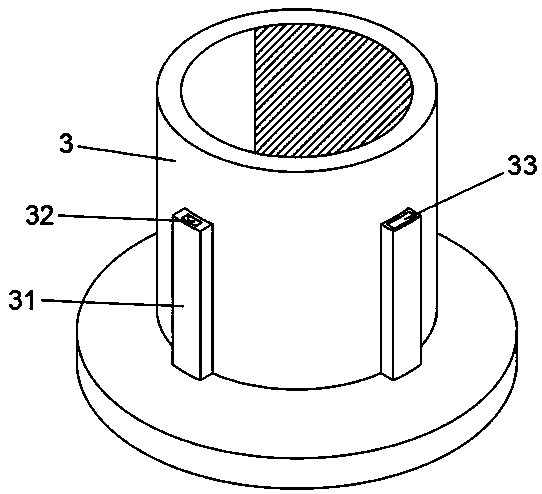

Image

Examples

Embodiment 2

[0037] Embodiment 2, double-threaded nut preparation process, including S1 raw material selection: select titanium alloy, easy-car iron, aluminum alloy and copper, and then carry out corresponding material inspection in strict accordance with the IQC operation guide;

[0038] S2 Nut Preparation: Using a lathe, separately turn out spherical nuts and hexagonal nuts with the same lower holes;

[0039] S3 Double Nut Welding: Transfer a single spherical nut and a single hexagonal nut to the designated position through the transmission device, and then perform the welding process;

[0040] S4 Nut Tapping: Tap the nuts welded together from the end of the hexagonal nut to the end of the spherical nut, and the length of the thread is two-thirds of the total length of the nut;

[0041] S5 Nut Opening: Open the welded nut from the center of the spherical end to the corresponding opening operation, and the length of the opening is less than one-third of the total length.

[0042] S6 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com