Fabric continuous dyeing device

A dyeing device and fabric technology, applied in the field of clothing manufacturing, can solve the problems of dye waste, environmental pollution, inconvenient dye stirring and adsorption, etc., and achieve the effect of preventing dye leakage and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

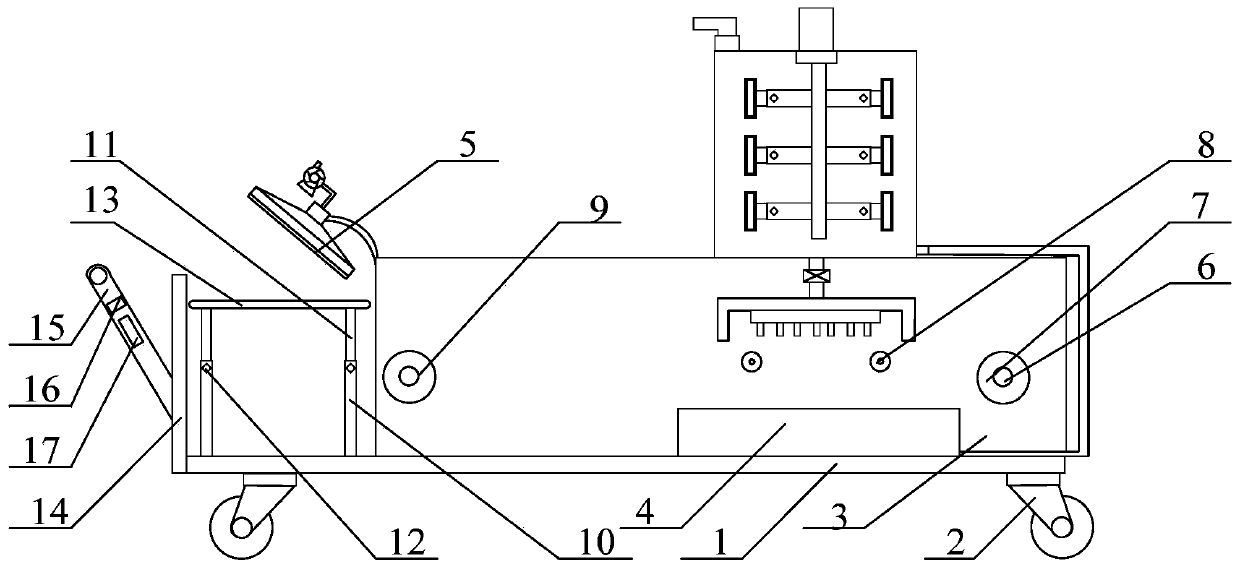

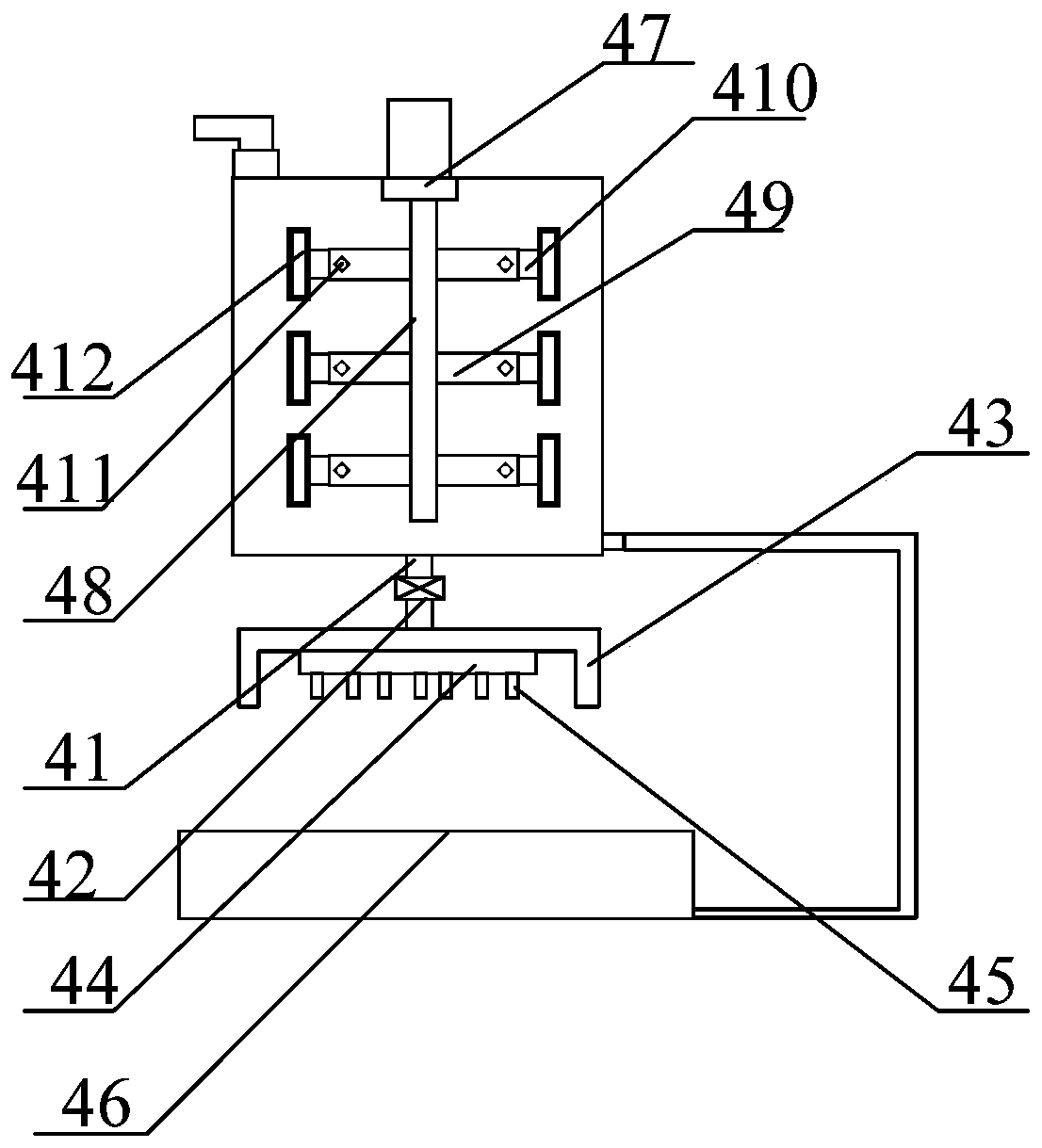

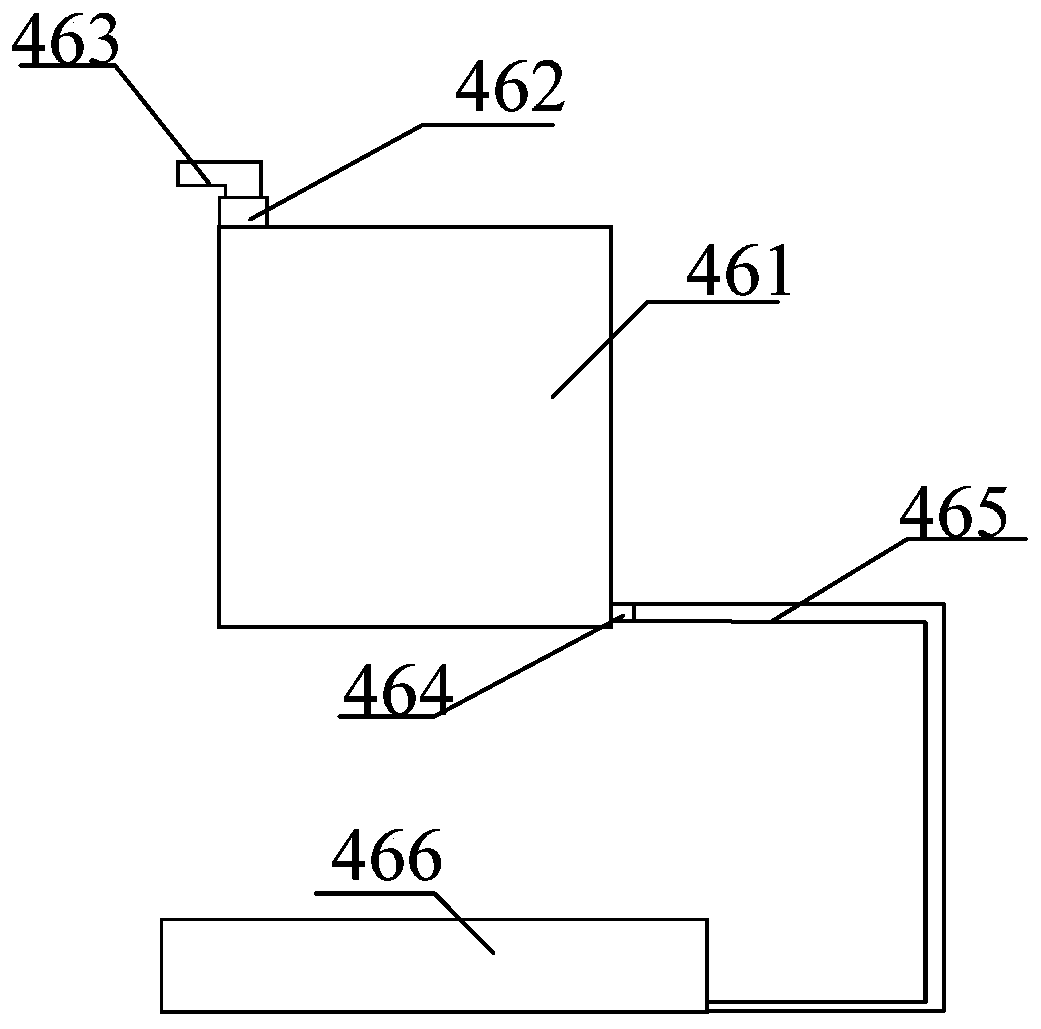

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

[0035] as attached figure 1 And attached figure 2As shown, a fabric continuous dyeing device according to the present invention includes a bottom plate 1, a moving wheel 2, a protective shell 3, a fabric dyeing dye storage cycle stirring box structure 4, an adjustable protective fabric drying rack structure 5, and a conveying motor 6. Fixed wheel 7, auxiliary wheel 8, conveying wheel 9, socket pipe 10, inserting rod 11, adjusting bolt 12, articulated rod 13, support plate 14, pull rod 15, control switch 16 and PLC17, and the moving wheels 2 are respectively bolted Connected at the four corners of the base plate 1; the protective shell 3 is bolted to the right side of the upper surface of the base plate 1; the fabric dyeing dye storage circulation mixing tank structure 4 is arranged on the right side of the upper surface of the protective shell 3; Adjust the protective fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com