Rapeseed oil filling and conveying structure

A rapeseed oil and filling technology, which is applied in packaging, liquid bottling, bottle filling, etc., can solve the problems that the filling and conveying cannot be carried out synchronously, so as to ensure operation consistency, stability, and operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

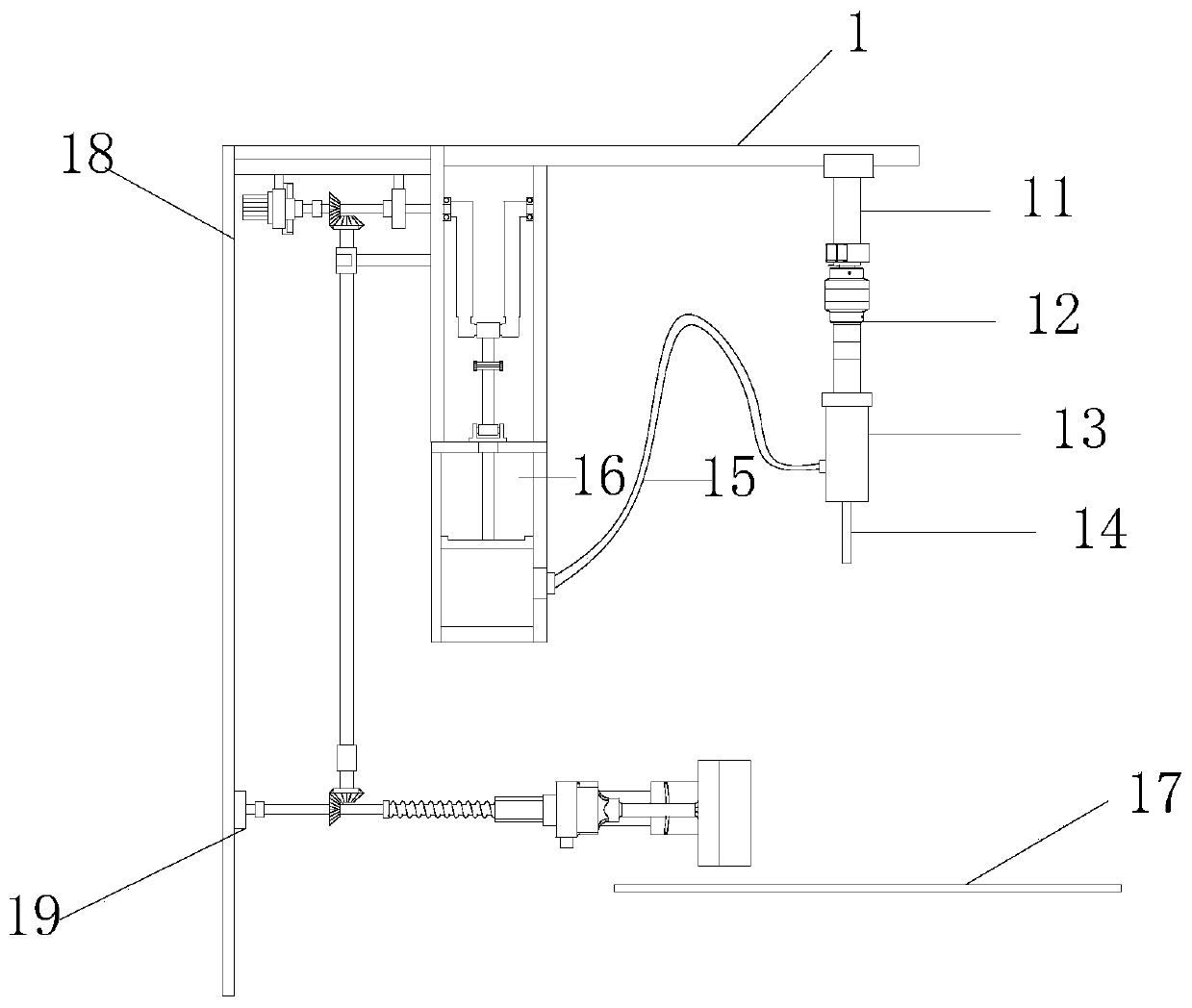

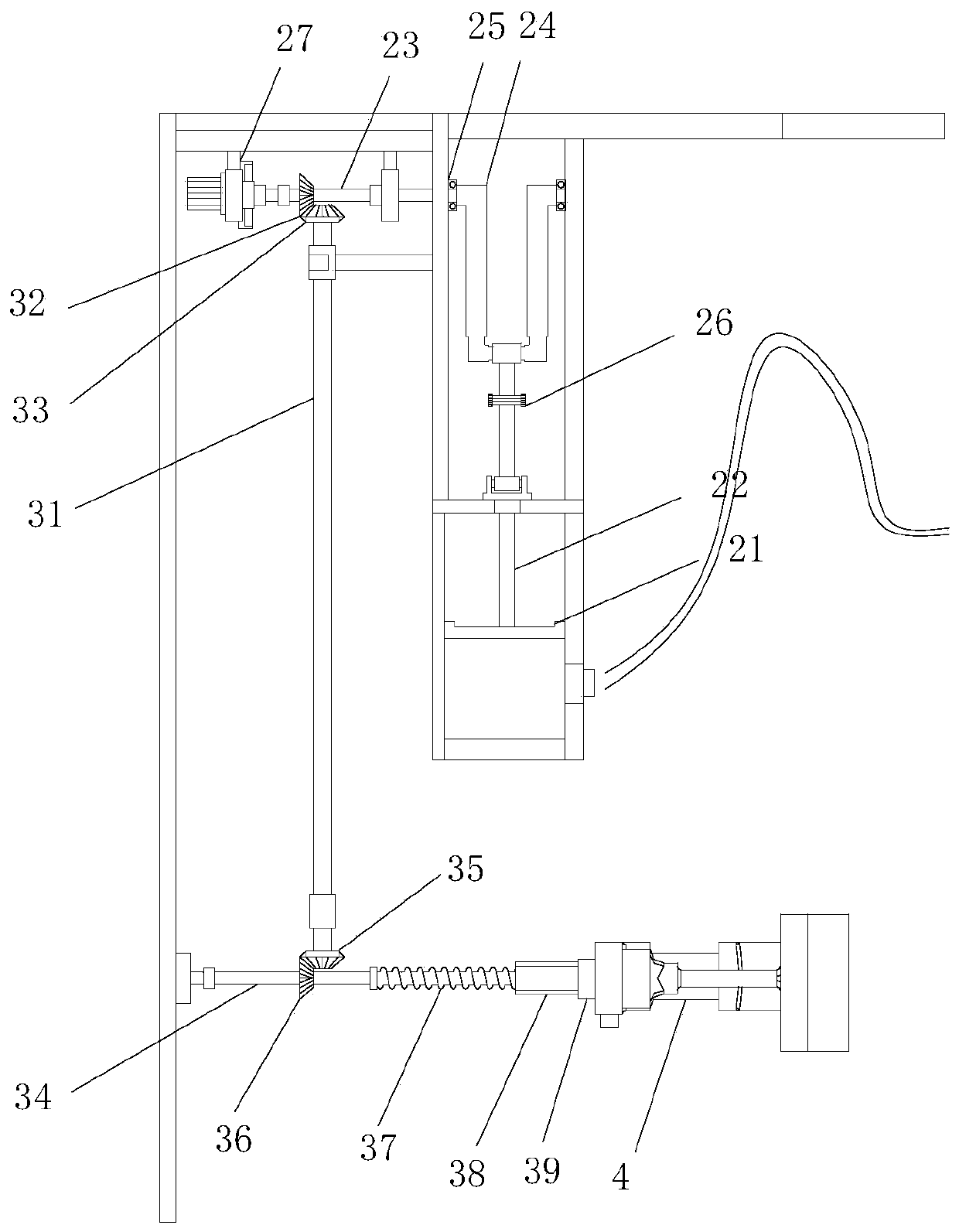

[0025] see figure 1 and figure 2 , a filling rapeseed oil conveying structure, comprising a working frame 1, a conveyor belt 17 is arranged below the working frame 1, a mounting frame 11 is arranged on the top plate of the working frame 1, and the bottom end of the mounting frame 11 An electric telescopic rod 12 is provided, and the bottom end of the electric telescopic rod 12 is provided with a perfusion tube 13, and the bottom of the perfusion tube 13 is provided with a perfusion head 14, and the work frame 1 is also provided with a feeding tube 16. The feeding end of the feeding tube 16 is externally connected with an infusion tube 15, and the infusion tube 15 is connected with the perfusion tube 13 again. In this application, the conveyor belt 17 is used for conveying materials, the electric telescopic rod 12 is used for adjusting the height position of the filling cylinder 13, and the filling cylinder 13 is used for the filling operation of rapeseed oil.

[0026] A pis...

Embodiment 2

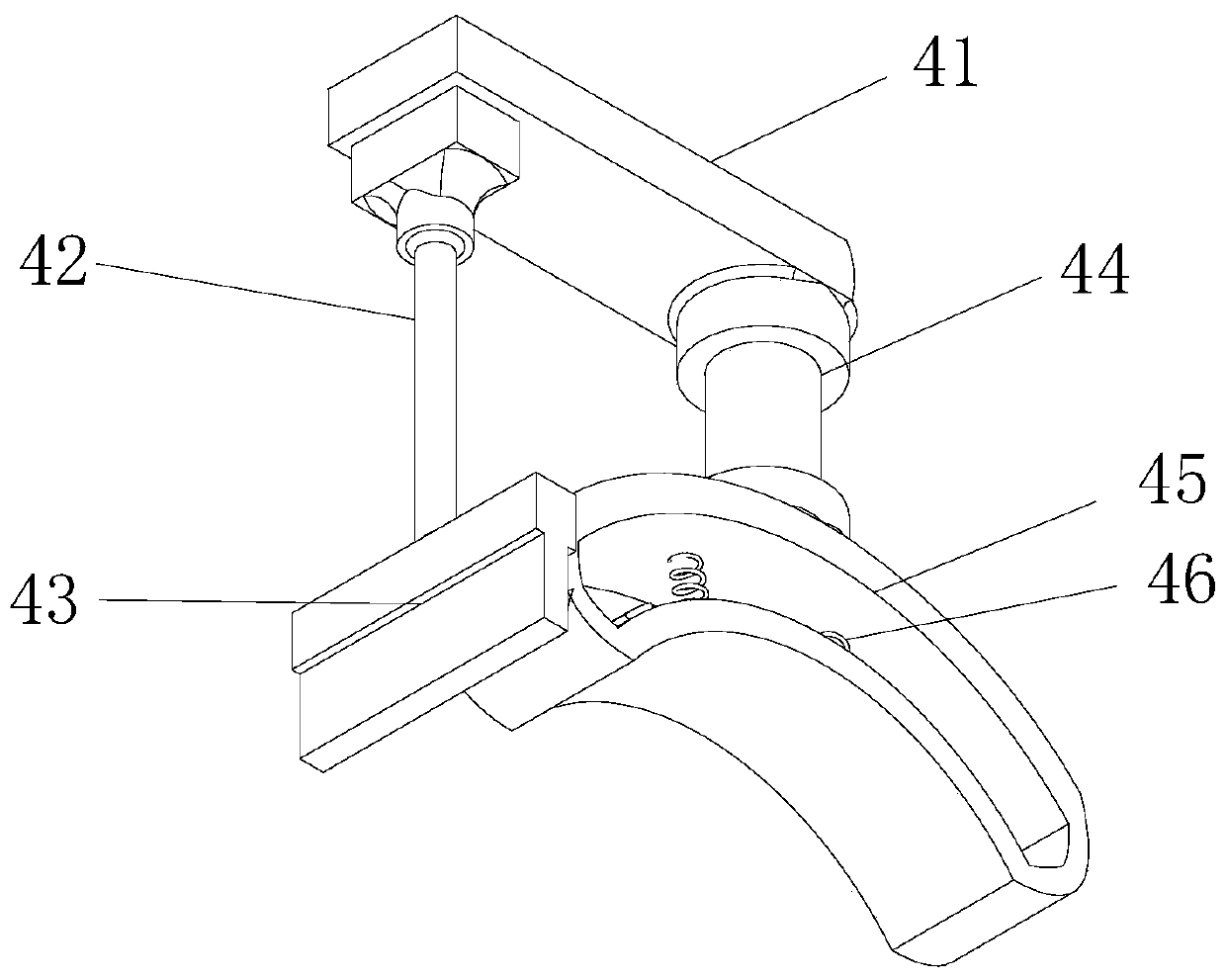

[0029] see figure 1 and image 3 , this embodiment is a further optimization of the first embodiment, on the basis of which, the spacer 4 includes a base plate 41, the base plate 41 is installed with a side edge strut 42 on the outside, and the side edge strut 42 A baffle 43 is installed at the end of the rod, and a support rod 44 is also arranged on the base plate 41. A clamping hoop 45 is installed on the support rod 44. The clamping hoop 45 adopts a soft structure and is designed as an arc-shaped inner Concave structure, the hoop body of the clamping hoop 45 is also an inner hollow structure and several inner support springs 46 are installed inside.

[0030] This application is not only provided with a baffle 43 for blocking, but also provided with a clamping hoop 45 to clamp the poured pot body. The support spring 46 forms an inward clamping support force, thereby ensuring the stability of the kettle body during pouring, and avoiding the problem that the kettle body shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com