Automatic car process integrated device

A technology of automatic vehicles and processing devices, which is applied in the direction of manufacturing tools, metal processing, and other manufacturing equipment/tools, etc. It can solve problems such as unsatisfactory production needs, unsafe manual operations, and low operating efficiency, so as to save processes and reduce manpower use and reduce the effect of dangerous operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

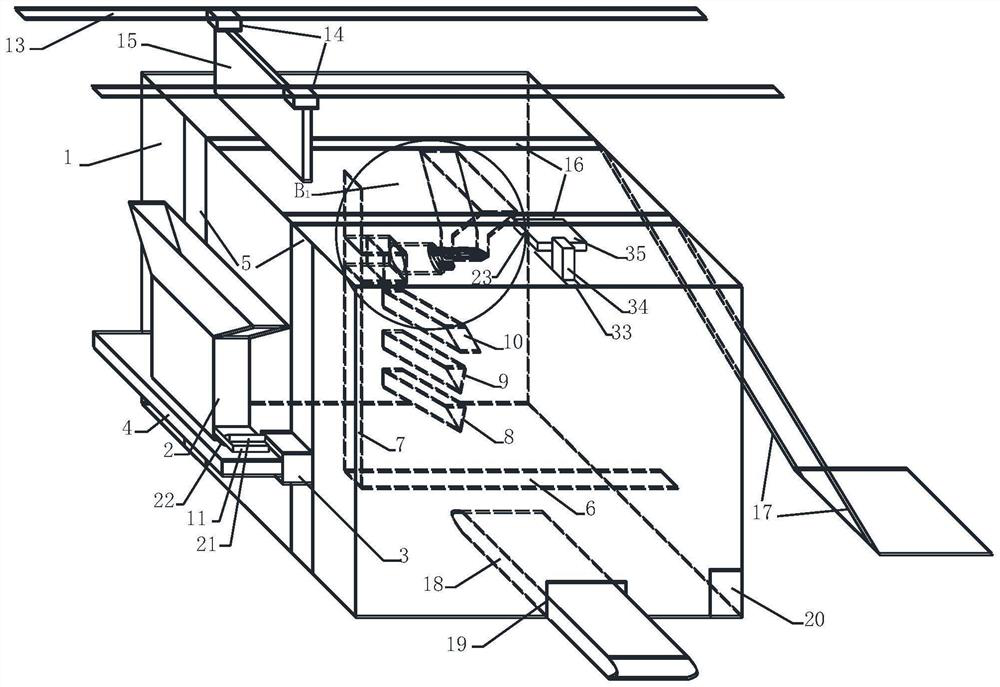

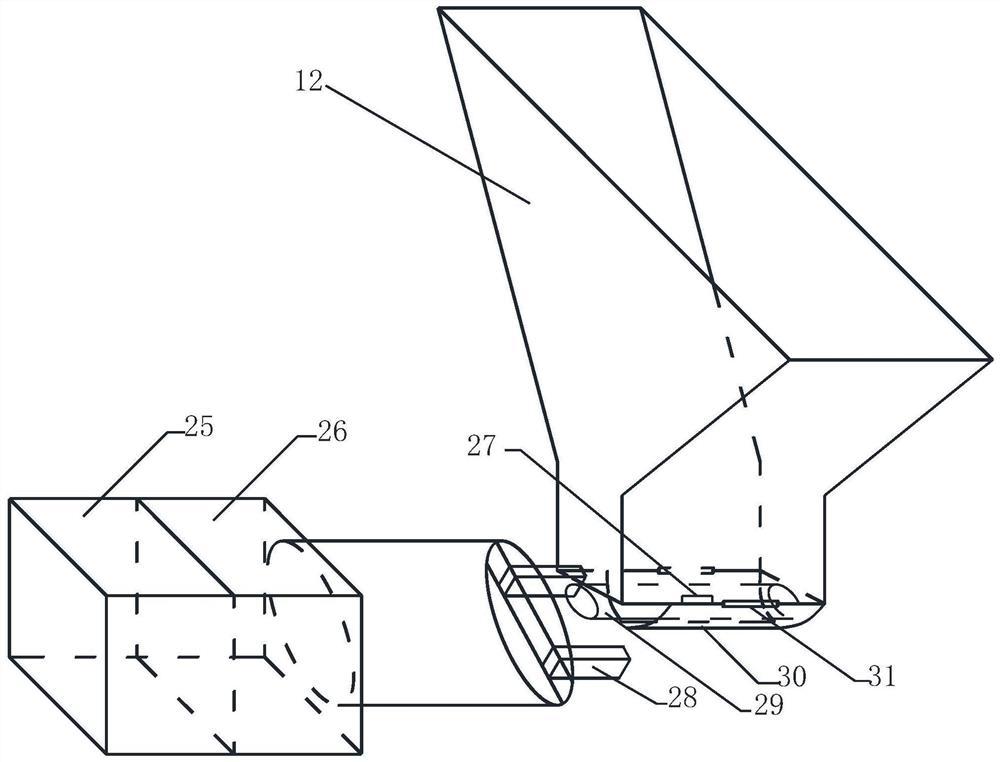

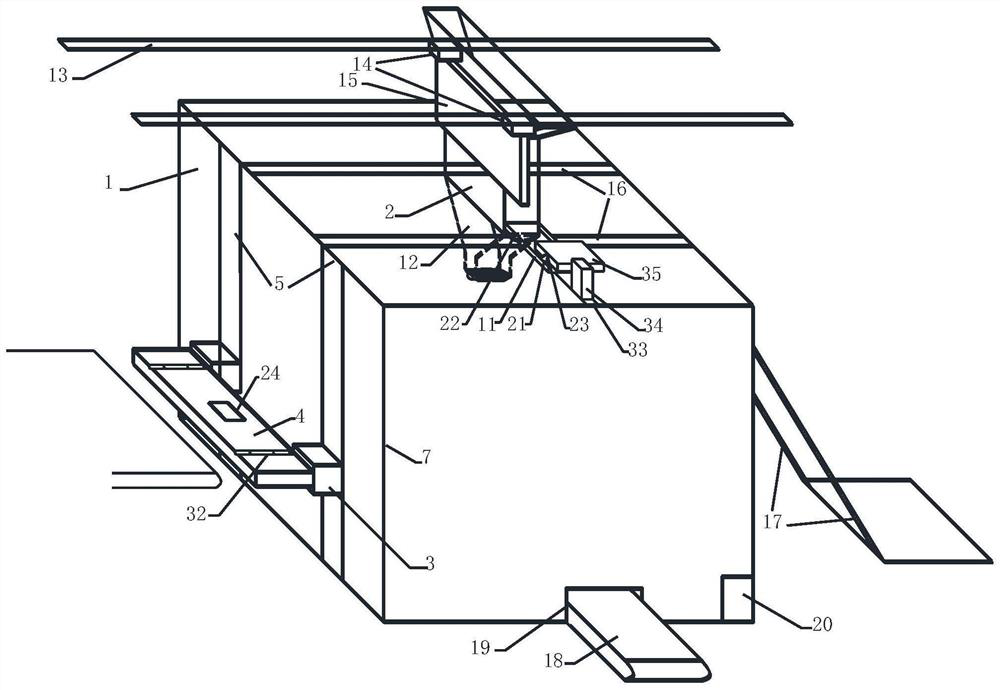

[0022] The present invention will be further described below according to the accompanying drawings and some implementations.

[0023] Figure 1-5 Among them, an automatic lathe process integrated device, comprising a machine tool main body 1, an automatic feeding device capable of conveying the shaft 29 to the machine tool main body 1, the automatic feeding device is located above the machine tool main body 1, and is fixed to the upper end surface of the machine tool main body 1; The machine tool body 1 is provided with a comprehensive processing device capable of milling, flattening, grooving, and threading the shaft 29, and a transfer processing device that can transport the shaft 2 to the output end of the comprehensive processing device for processing. The input end of the transfer processing device is connected to the automatic Corresponding to the output end of the feeding device, the output end of the transfer processing device can transport the shaft 29 to the next pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com