Laser inscription equipment for hubs

A laser engraving and wheel hub technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of limited engraving accuracy, limited recognition ability, increased enterprise costs, easy to make mistakes, etc., to improve lettering Efficiency and accuracy, reducing product scrap rate, saving production resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

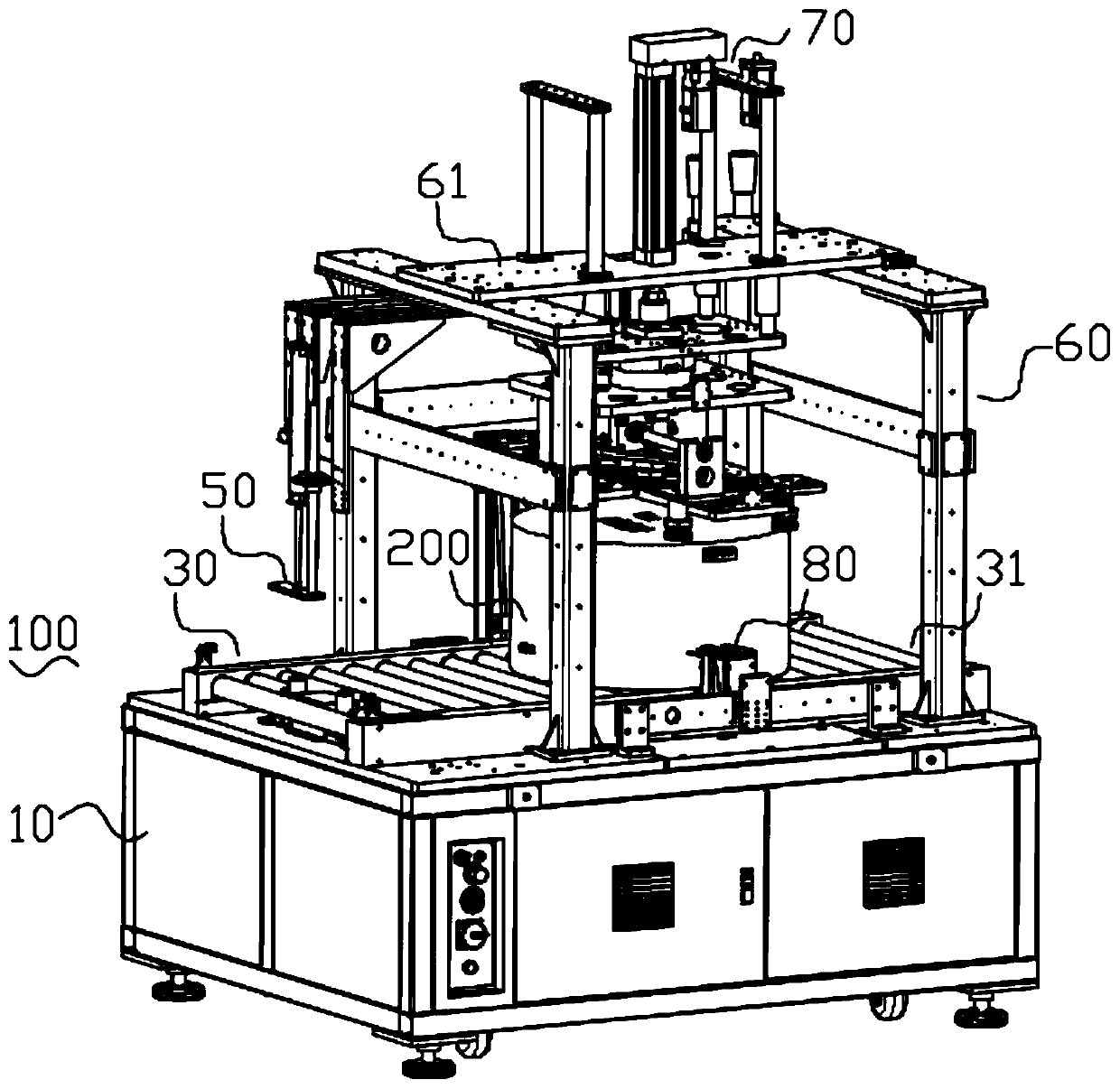

[0029] Embodiment: The present invention proposes a kind of laser engraving equipment 100 for hub, please refer to Figure 1-3 As shown, it includes a hub conveying mechanism, a hub height measuring mechanism 50, a clamping and rotating mechanism 70, a one-dimensional code scanning recognition mechanism, a laser engraving mechanism 90, and an upper sheet metal cover 20 arranged up and down outside the above-mentioned mechanisms. and the lower sheet metal housing 10; wherein,

[0030]The hub conveying mechanism, which is arranged on the top of the lower sheet metal housing 10 and is covered by the upper sheet metal housing 20, includes a feed roller table 30 and a discharge roller table 31, which are used to transport hub feed and discharge respectively; and There is a truss 60 on it, and the top of the truss 60 is fixedly connected with a beam 61 by bolts, and the upper sheet metal cover 20 is covered outside the truss 60 and the beam 61, wherein the upper sheet metal cover 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com