Double-head spray gun

A technology of double-head spray gun and gun body, applied in the direction of spray device, liquid spray device, etc., can solve the problems of increased scattering angle, dead angle of docking angle, and more compressed air, and achieves reduced compressed air, reduced scattering angle, and dust. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

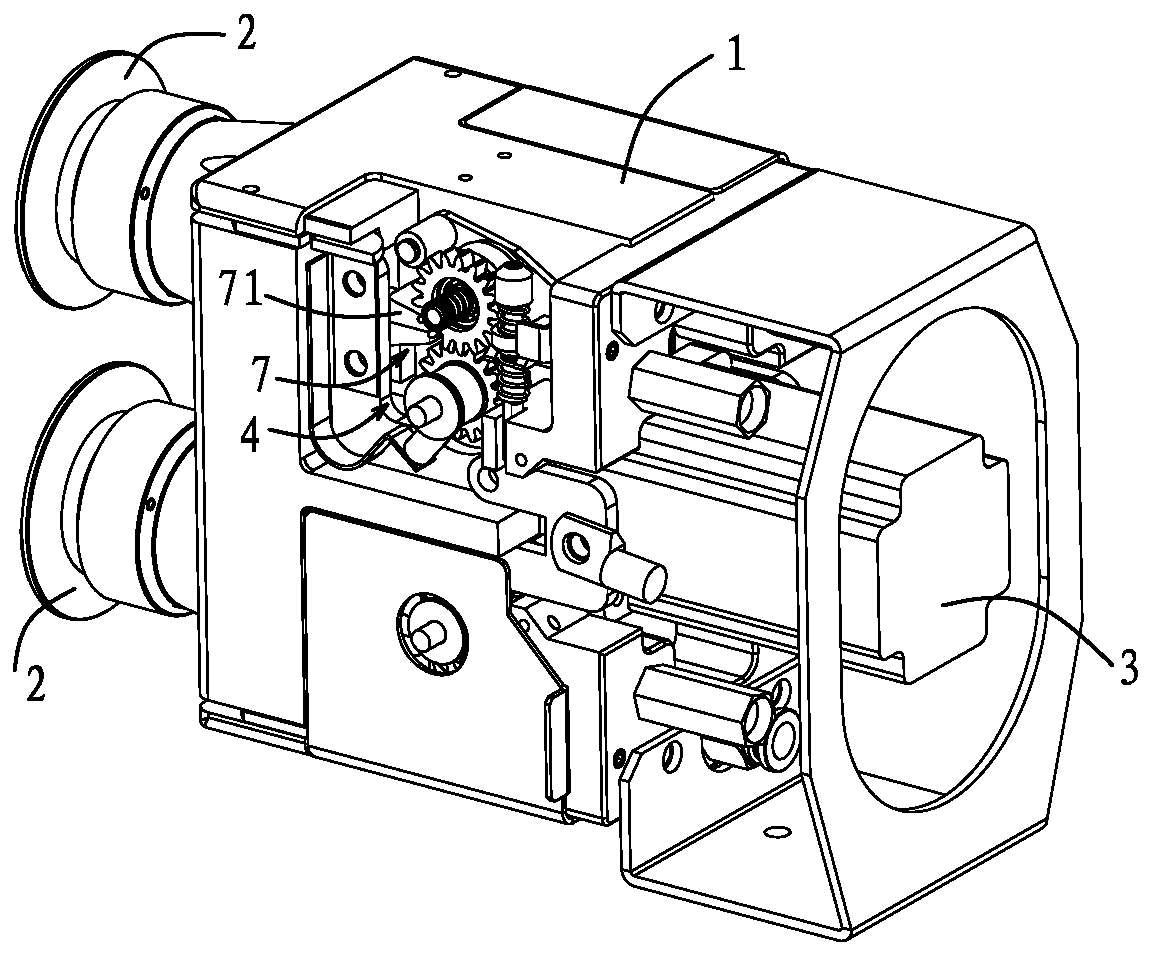

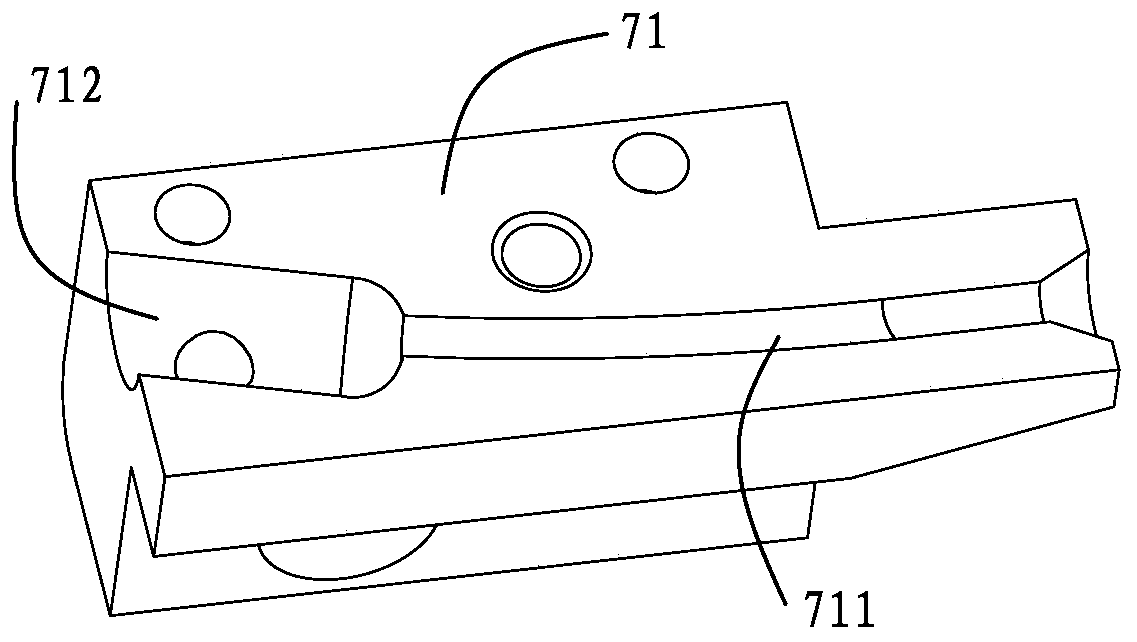

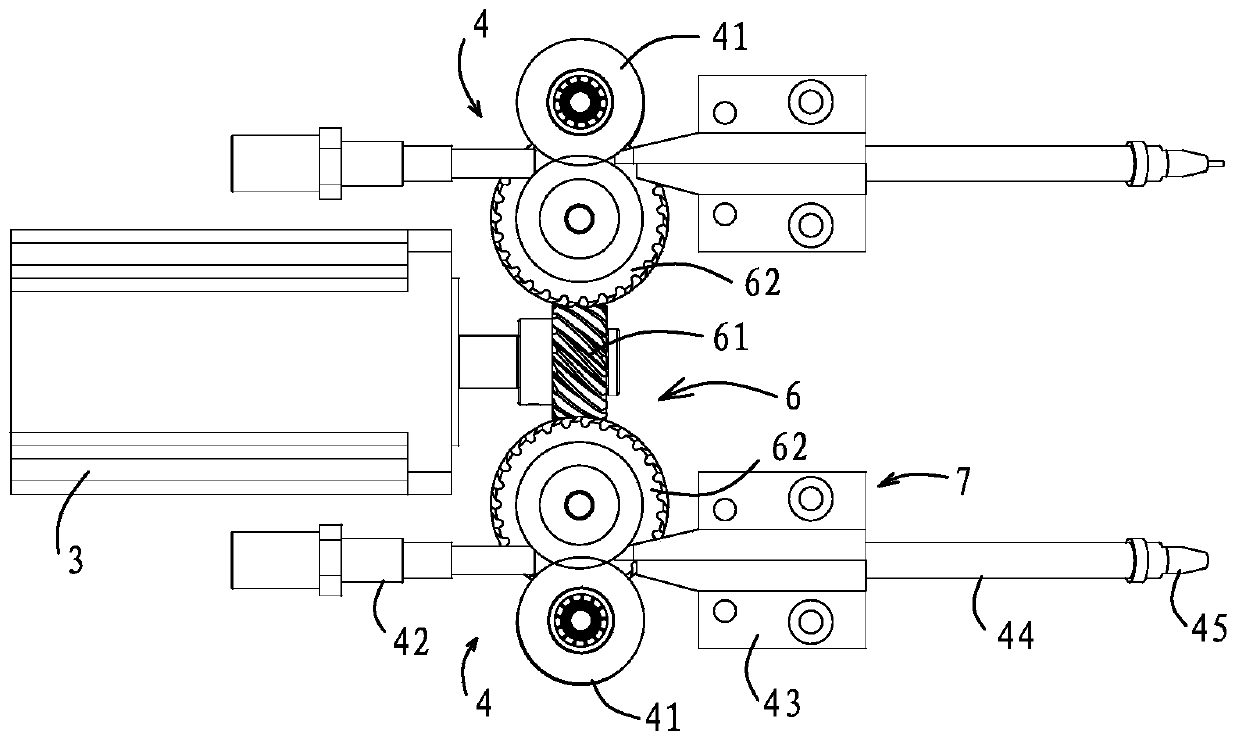

[0020] refer to Figure 1 to Figure 5 . Double-head spray gun, including gun body 1, gun head 2, motor 3 and wire feeding mechanism 4, gun head 2 is set at one end of gun body 1, two gun heads 2, motor 3 is set on gun body 1, wire feeding There are four mechanisms 4, all of which are connected with the output shaft of the motor 3. Every two wire feeding mechanisms 4 are correspondingly arranged with a gun head 2. The gun body 1 is provided with an air supply pipeline 5, which corresponds to the gun head 2. That is, the high-speed compressed gas delivered by the gas supply pipeline 5 acts on the gun head 2 places. Wherein, the motor 3 is a servo motor, which replaces the common motor used in the prior art. The double-headed spray gun is driven by a servo motor, which reduces the overall weight of the spray gun and makes the wire feeding mechanism 4 more stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com