Low-noise food processor

A food processing machine with low noise technology, applied in the field of food processing, can solve the problems of high noise of the wall breaking machine, user troubles, etc., and achieve the effect of reducing noise and improving the wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

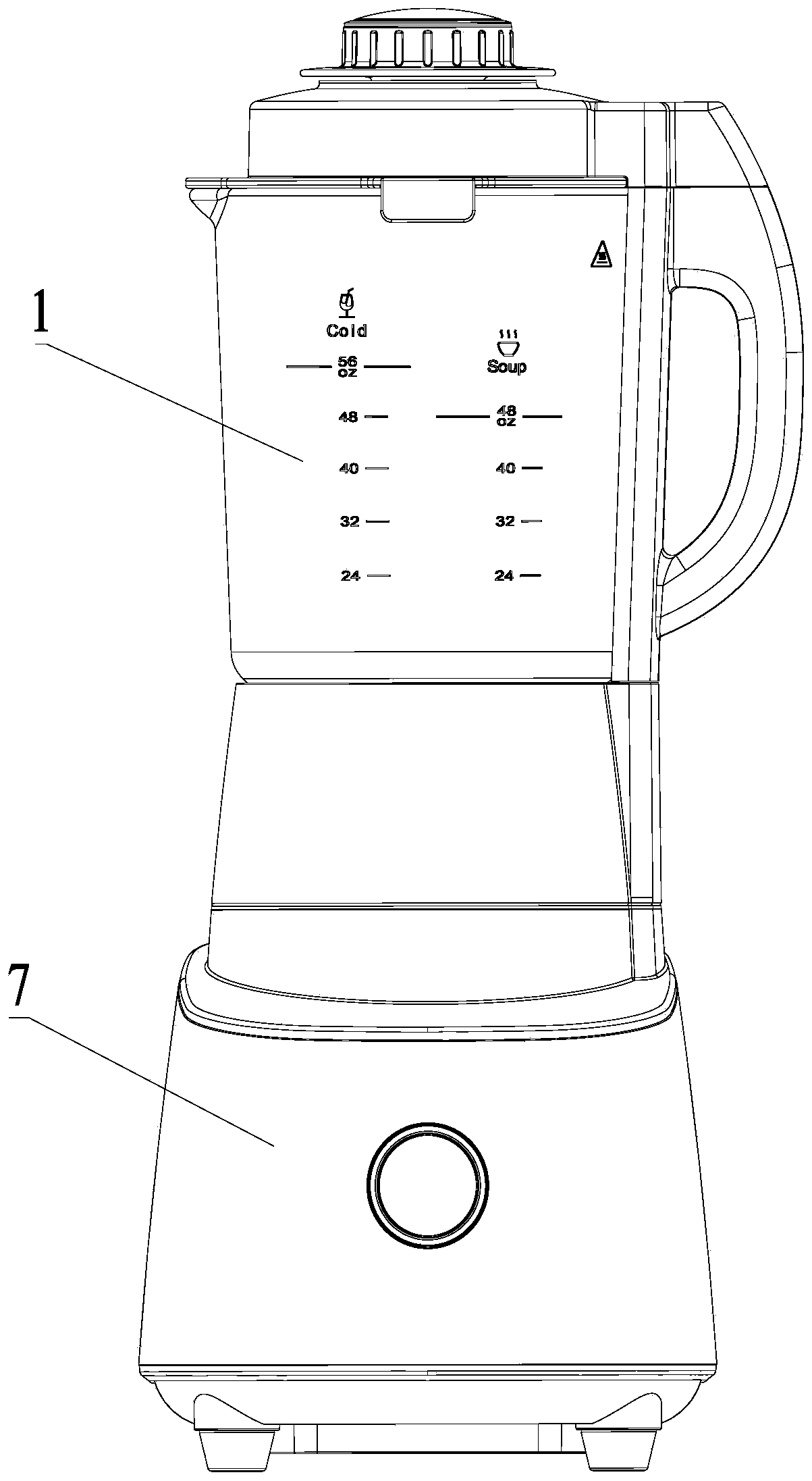

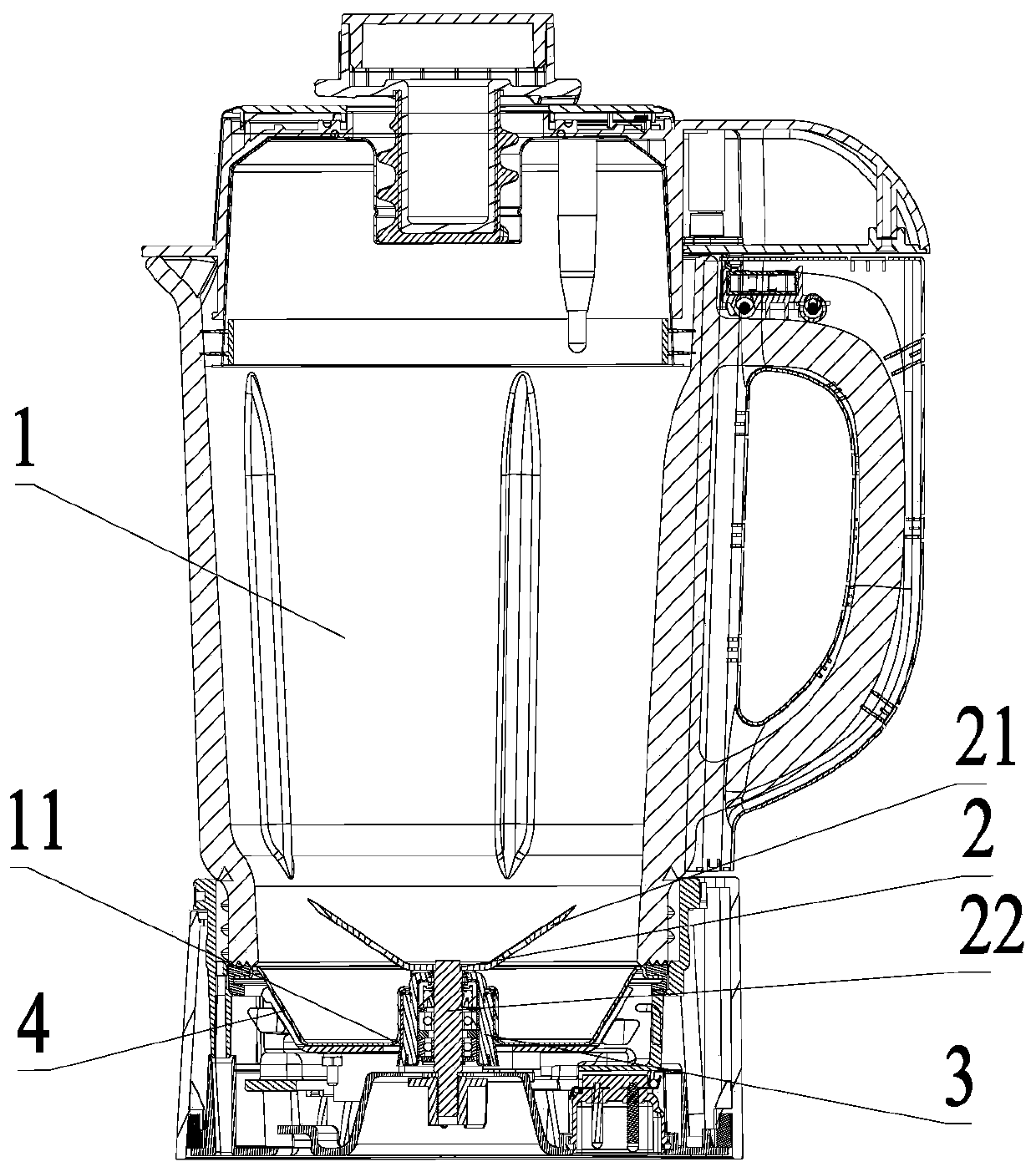

[0043] In an exemplary embodiment of the present invention, as Figure 1 to Figure 8 As shown, the embodiment of the present invention provides a food processor with low noise, such as figure 1 , figure 2 As shown, the food processor includes a machine base 7, a motor (not shown in the accompanying drawings), a stirring cup 1 installed on the machine base and a crushing knife 2 installed at the bottom of the stirring cup 1, and the crushing knife 2 includes a blade 21 and a knife shaft 22. The bottom of the mixing cup 1 is provided with a mounting hole 11 for installing the bushing 3, and the cutter shaft 22 passes through the bushing 3 to drive and cooperate with the motor shaft of the motor.

[0044] In order to ensure the concentricity of the cutter shaft 22 and the shaft sleeve 22, as image 3 As shown, the sleeve 3 includes a rigid inner wall 31 for surrounding the cutter shaft 21 to position the cutter shaft 21 , a rigid outer wall 32 matching the mounting hole 11 , a...

Embodiment 2

[0066] The main difference between this embodiment and Embodiment 1 is that the food processing machine of this embodiment is provided with a supporting member 333 supporting the root of the blade 21 .

[0067] Specifically, such as Figure 9 to Figure 14 As shown, in order to reduce the contrast caused by the swing of the blade 21 rotation, as Figure 9 , Figure 10 As shown, the elastic ring 331 protrudes upwards and is provided with a supporting member 333 supporting the root of the blade 21. The supporting member 333 is used to limit the swing range of the crushing knife 2 when it rotates. When the processing machine is working, the blade 21 is prone to vibration due to high-speed rotation, and there is a certain swing range up and down. By setting the support member 333 on the lower side of the root of the blade 21, when the blade 21 has a certain swing range up and down, the root of the blade 21 The lower side will first touch the supporting piece 333, which will exert...

Embodiment 3

[0078] The main difference between this embodiment and Embodiment 1 and Embodiment 2 is that the lower side of the elastic ring 331 of the food processor in this embodiment is recessed upwards to provide an accommodating cavity 3311 for accommodating the upper positioning ring 311 .

[0079] Specifically, such as Figure 15 As shown, in order to further improve the wrapping effect on the top of the rigid inner wall 31, the rigid inner wall 31 of this solution includes an upper positioning ring 311, and the lower side of the elastic ring 331 is concavely provided with an accommodating cavity 3311 for accommodating the upper positioning ring 311. The elastic ring 331 Wrap the top of the rigid inner wall 31 from the upper side and its surroundings, that is, wrap the upper positioning ring 311 from the upper side and its surroundings. 311 is wrapped on the upper side and around to realize the isolation of noise transmission upwards and to the surroundings, which better isolates th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com