A fast reflective surface unit self-adaptive connection mechanism replacement method

A technology of connection mechanism and replacement method, which is applied to electrical components, antennas and other directions to achieve the effects of low labor intensity, low construction cost and fast progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

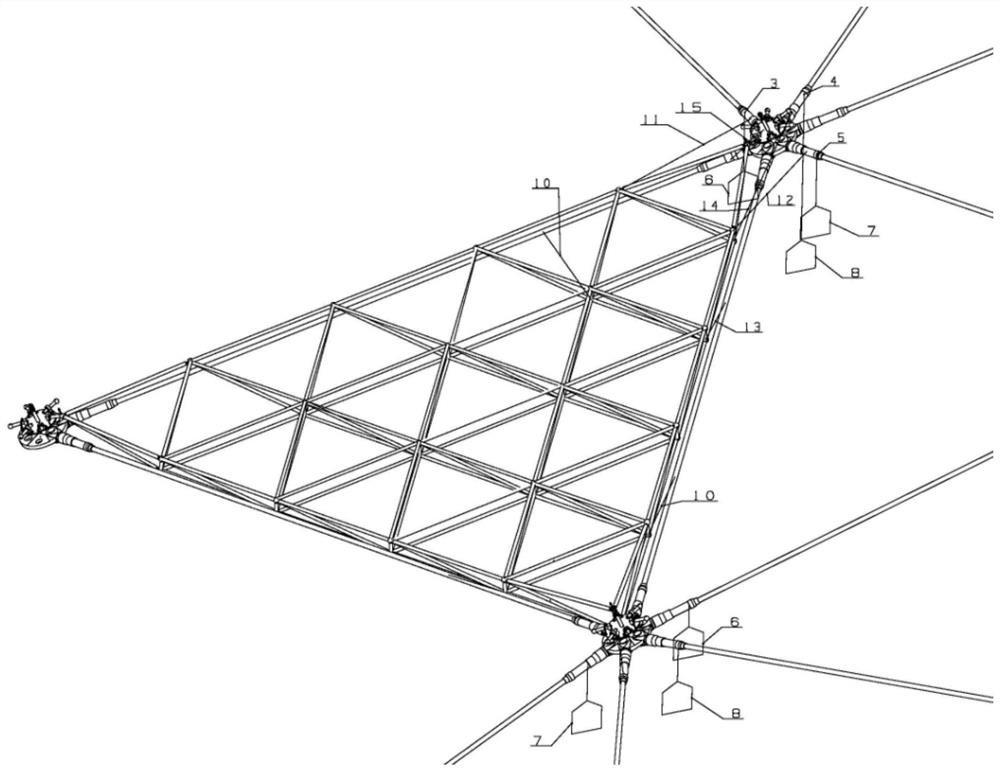

[0055] The invention provides a method for replacing an adaptive connection mechanism of a FAST reflective surface unit, which includes the following steps:

[0056] installation of hanging points;

[0057] The climbing platform 8 is installed and climbed to the construction position;

[0058] Install a set of hanging baskets on both sides of the connecting mechanism to be replaced and strengthen the hanging baskets for the manned construction platform.

[0059] Flip and remove the corresponding position of the self-adaptive connection mechanism to be replaced (the 1# end shaft connector is replaced with the 0# end shaft new connector position 1 or the 0# end shaft connector is replaced with the 1# end shaft new connector position 2) reflection Small panels at corners of face elements;

[0060] Install the force system conversion device;

[0061] Adjust the position of the end axis of the reflective surface panel;

[0062] The gravity of the reflecting surface panel is tra...

Embodiment 2

[0078] Embodiment 2 provides a method for replacing the 1# connection mechanism of the FAST reflection surface unit with a 0# connection mechanism. This embodiment adds a method for replacing the 1# connection mechanism of the FAST reflection surface unit with a 0# connection mechanism on the basis of Embodiment 1. #Another technical solution of the connection mechanism, the technical features disclosed in the first embodiment are also applicable to the second embodiment, and the technical features disclosed in the first embodiment will not be described again.

[0079] The method of replacing the 1# connection mechanism of the FAST reflector unit with the 0# connection mechanism includes the following steps:

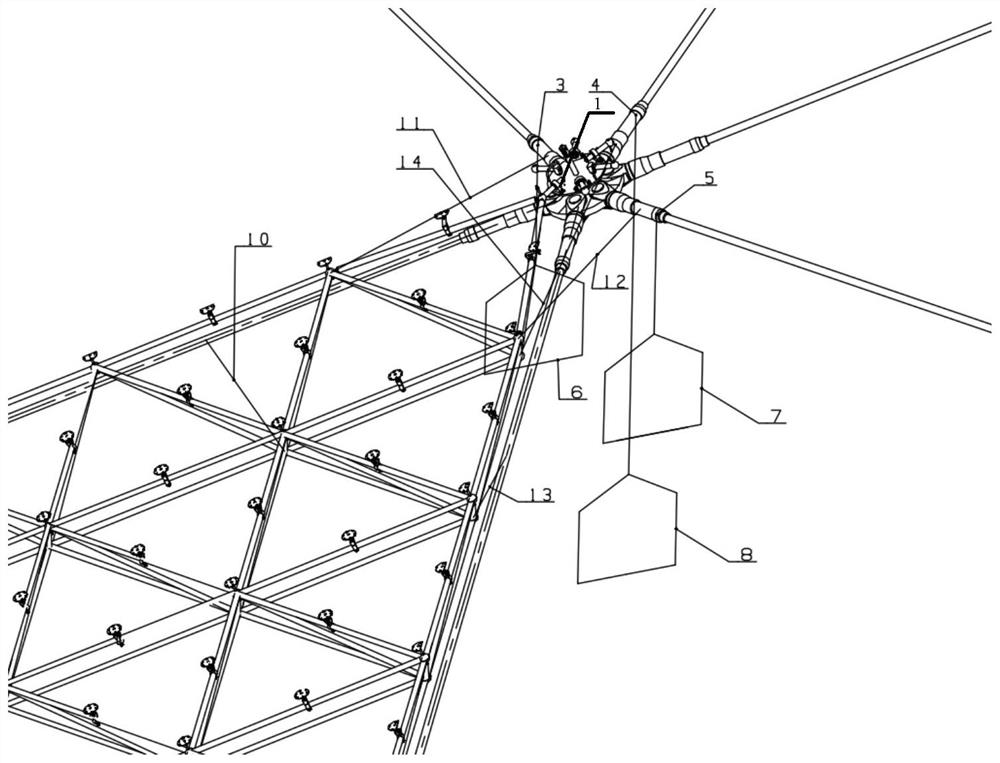

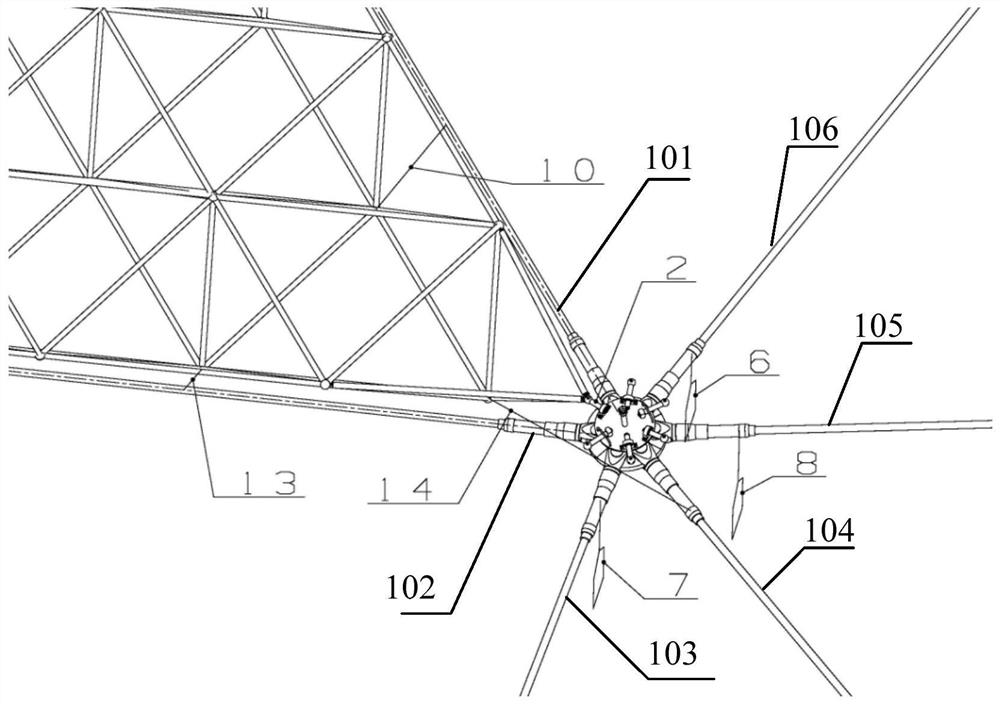

[0080] (1) The "Spiderman" slides from the position of the ring beam along the main cable to the position of the joint plate where the connection mechanism needs to be replaced, and installs the first lifting point 3, the second lifting point 4 and the third lifting point...

Embodiment 3

[0093] Embodiment 3 provides a method for replacing the 0# connection mechanism of the FAST reflector unit with the 1# connection mechanism. This embodiment adds a method for replacing the 0# connection mechanism of the FAST reflector unit with 1# on the basis of Embodiment 1. #Another technical solution of the connection mechanism, the technical features disclosed in the first embodiment are also applicable to this embodiment, and the technical features disclosed in the first embodiment will not be described again.

[0094]The main steps of replacing the 0# connecting mechanism of the FAST reflector unit with the new connecting piece of the 1# end shaft are as follows:

[0095] (1) The "Spiderman" slides from the position of the ring beam along the main cable to the position of the node plate where the connection mechanism needs to be replaced, and installs the first lifting point 3, the second lifting point 4 and the third lifting point 5, and the first lifting point 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com