Reconfigurable production line scheduling optimization method for small-batch multiple varieties

A technology of production line scheduling and optimization methods, applied in the direction of reasoning methods, design optimization/simulation, genetic rules, etc., can solve problems such as urgent tasks, uncertain completion time, and difficult progress control, so as to enhance the degree of intelligence and optimize resources The effect of the configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with an example, but the embodiment of the present invention is not limited to this example.

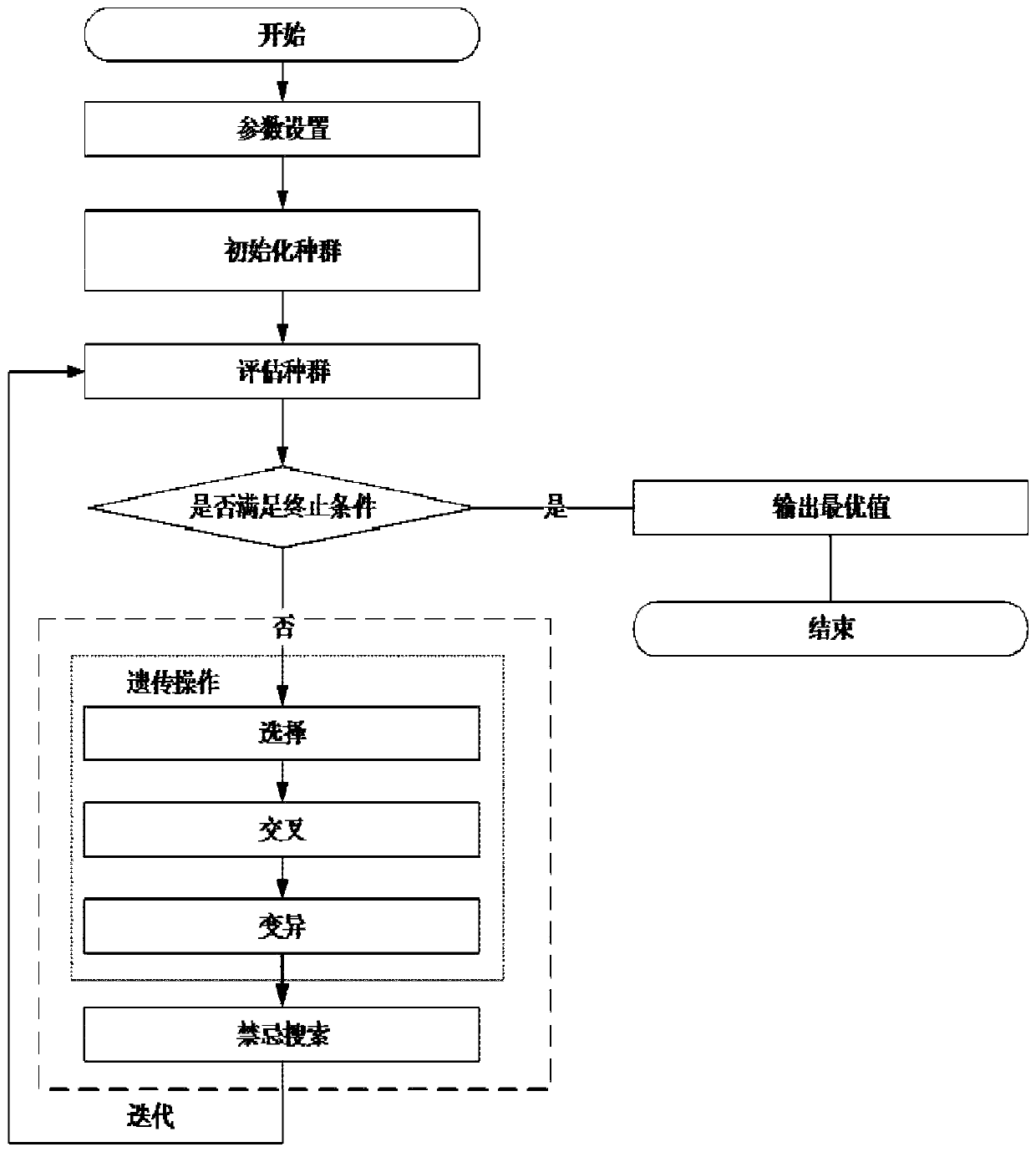

[0047] A reconfigurable production line scheduling optimization method for small batches and multiple varieties of the present invention is implemented through the following steps.

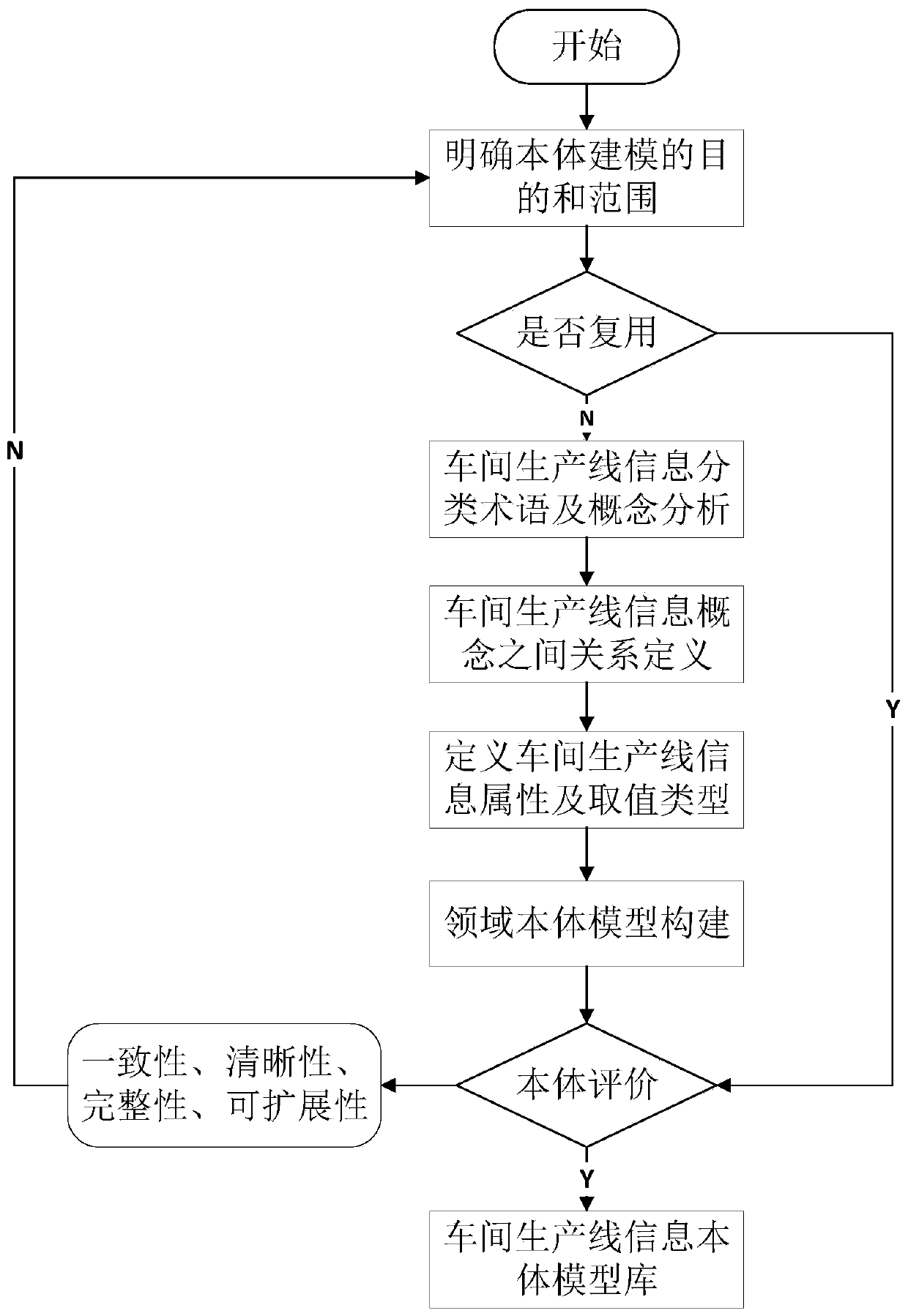

[0048] 1. Modeling process based on the production line field:

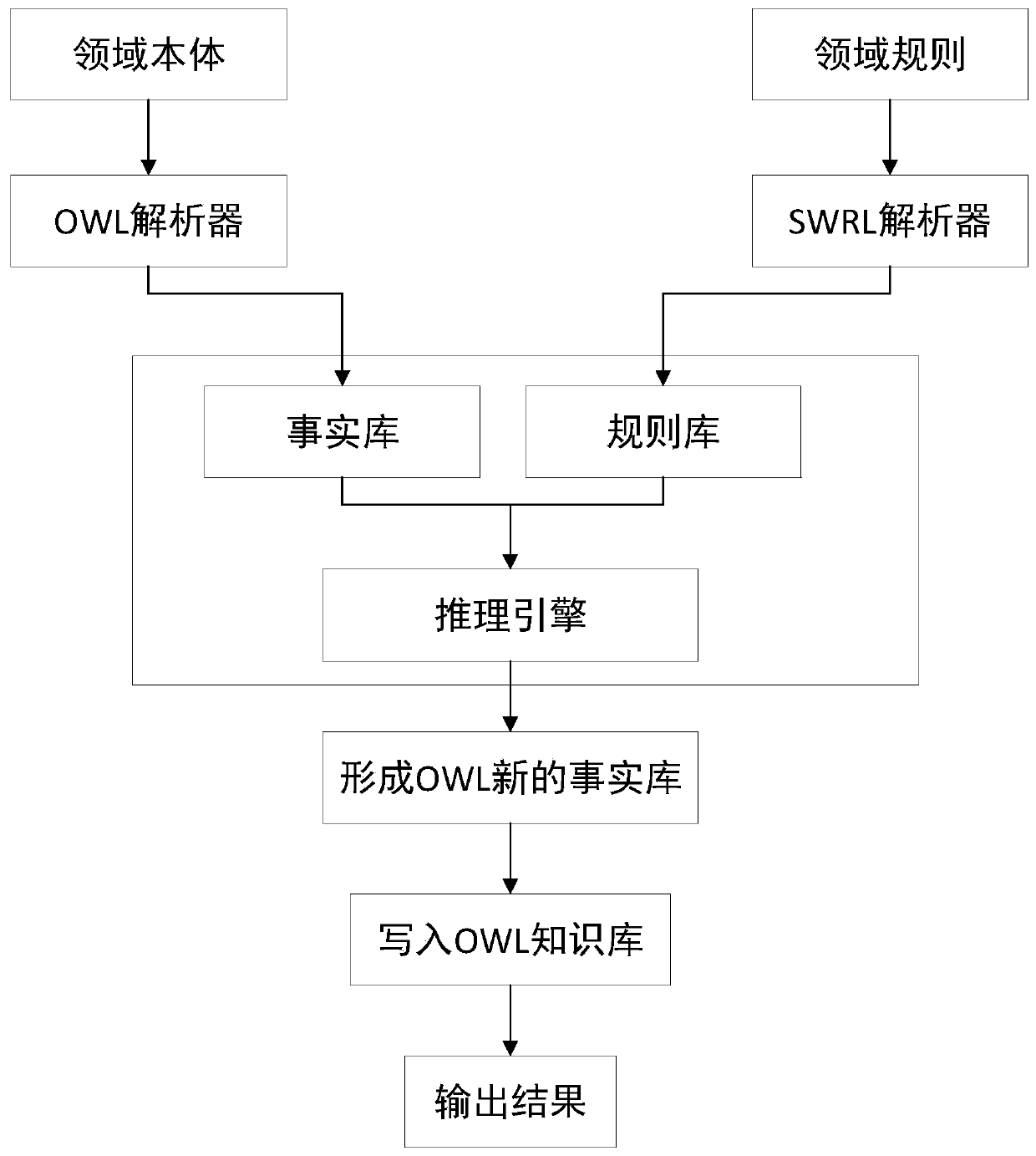

[0049]According to the system concept and logic in the field of flexible production line, combined with ontology modeling technology, the construction process of workshop production line information ontology model is given, and the ontology model of flexible production line entity is constructed. Ontology model is a modeling rule for a specific domain. Ontology is mainly composed of concepts, attributes, and instances. Concepts describe a certain thing and its characteristics from an abstract level, attributes describe the relationship between concepts, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com