Lightening liquid composition and its preparation method and application

A technology of smoothing liquid and composition, which is applied in the direction of lubricating composition, coating, metal material coating process, etc., can solve the problems affecting the post-treatment of galvanized sheet and the quality of passivated sheet, so as to improve the cleaning condition, Improved lubricity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In order to better realize the technical purpose of the present invention, the present invention also discloses the preparation method of the above-mentioned fairing liquid composition, which is characterized in that it comprises the following steps:

[0042] 1) Add composite rust inhibitor to deionized water, and stir until transparent under the condition of controlling temperature 45~55℃;

[0043] 2) After adding corrosion inhibitor and surfactant to the product obtained in step 1), continue to stir evenly;

[0044] 3) Add lubricant and composite additives to the product obtained in step 2), reduce the temperature to 35-45° C., and continue stirring until it becomes a transparent and uniform liquid, that is, a finishing liquid composition is prepared.

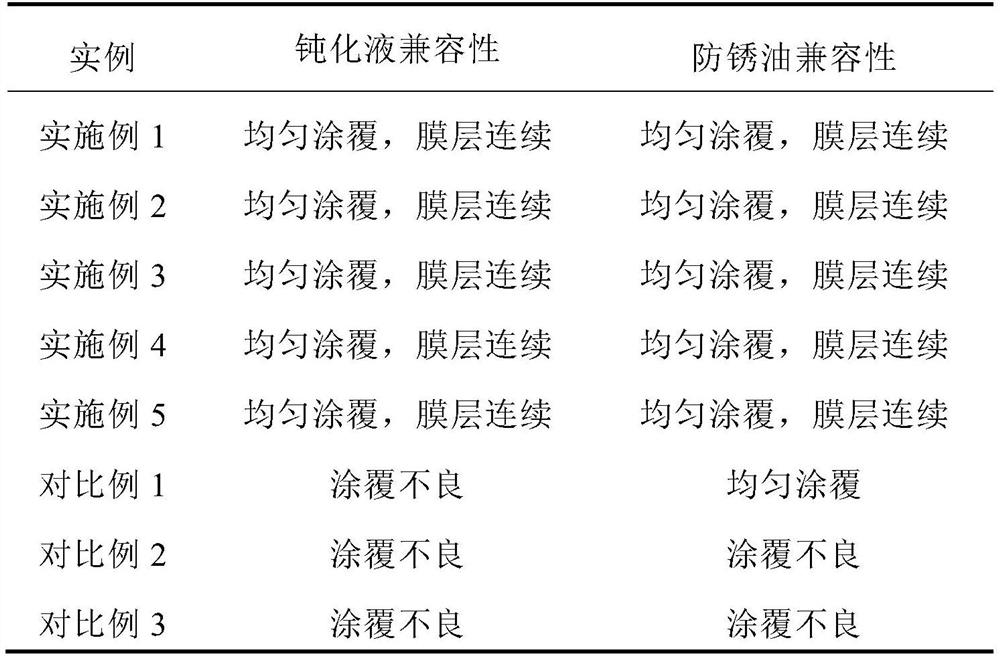

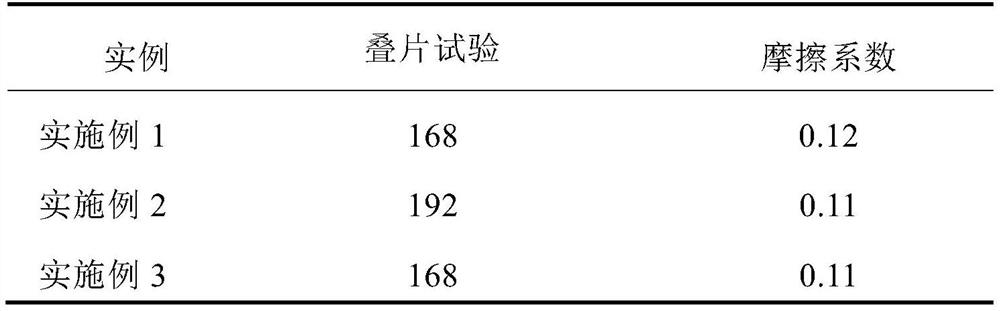

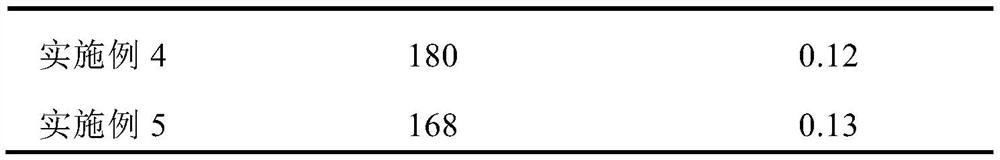

[0045] The fairing liquid composition prepared by the above formula and preparation method of the present invention has the characteristics of high salt resistance, low foaming property and easy formation of low viscos...

Embodiment 1

[0049] Add deionized water into the container, firstly add 8% boric acid, 10% hydroxylamine sulfate, and 12% acrylamide, stir for 20±5min at 50°C, and stir until transparent.

[0050]Then add corrosion inhibitor: 5% water-soluble imidazoline amide and 3% nonylphenoxyacetic acid, surfactant: 2% dodecyl polyoxyethylene glycol ether and 4% octylphenol poly Oxyethylene ether sulfate ammonium salt. Stirring was continued for 10 min.

[0051] Finally, 4% of sucrose methyl phenyl stearate and 2% of silane coupling agent were added, the temperature was lowered to 40° C., and the solution was continuously stirred until the solution was a transparent and uniform liquid to obtain the desired environmental-friendly finishing solution.

Embodiment 2

[0053] Add deionized water into the container, firstly add 4% boric acid, 5% hydroxylamine sulfate, and 6% acrylamide, and stir for 20±5min at 50°C until transparent.

[0054] Then add corrosion inhibitor: 3% water-soluble imidazoline amide and 1% nonylphenoxyacetic acid, surfactant: 1% dodecyl polyoxyethylene glycol ether and 2% octylphenol poly Oxyethylene ether sulfate ammonium salt. Stirring was continued for 10 min.

[0055] Finally, 2% of sucrose methyl phenyl stearate and 1% of silane coupling agent were added, the temperature was lowered to 40° C., and the solution was continuously stirred until the solution was a transparent and uniform liquid to obtain the required environmental protection finishing liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com