Self-repairing cross-linked polyurethane and preparation method thereof

A technology of polyurethane and ice-water bath, which is applied in the direction of organic chemistry, can solve the problems of increasing the consumption of polyurethane raw materials, easily producing cracked appearance, and destroying the ecological environment, etc., and achieves the effects of wide range of application effects, good self-repair function, and protection of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

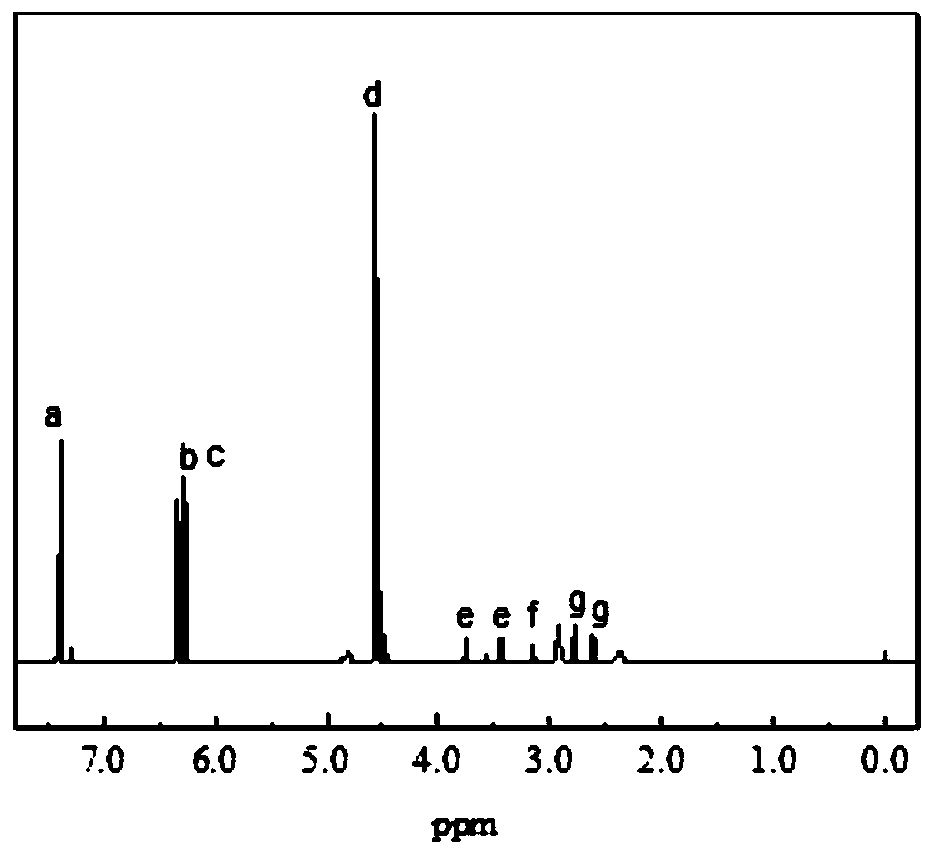

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing self-repairing cross-linked polyurethane, comprising the following steps:

[0044] S1. Mix 92.52g of epichlorohydrin and 98.1g of furfuryl alcohol, add the catalyst tetrabutylammonium bromide, put it into a 500ml three-necked flask, put it in an ice-water bath with a temperature of 2°C, and let it stand for 4 hours to obtain a mixed solution.

[0045] S2. Add 160ml of sodium hydroxide solution with a mass fraction of 50% dropwise to the mixed solution obtained in step S1, place it in an ice-water bath for 2 hours, extract it with anhydrous ether three times, wash it with water three times, and recover the ether by rotary steaming , and then dried with anhydrous magnesium sulfate, let it stand overnight, and then filtered it with suction. The solution was distilled under reduced pressure at 110°C to obtain a crude product, which was furfuryl glycidyl ether FGE.

[0046] S3. Take another 112.08g of furfurylamine, add it to a...

Embodiment 2

[0053] This embodiment provides a method for preparing self-repairing cross-linked polyurethane, comprising the following steps:

[0054] S1. Mix 92.52g of epichlorohydrin and 98.1g of furfuryl alcohol, add the catalyst tetrabutylammonium bromide, put it into a 500ml three-necked flask, place it in an ice-water bath with a temperature of 4°C, and place it for 3.5h to obtain a mixed solution .

[0055] S2. Add 160ml of sodium hydroxide solution with a mass fraction of 50% dropwise to the mixed solution obtained in step S1, place it in an ice-water bath for 2 hours, extract it with anhydrous ether three times, wash it with water three times, and recover the ether by rotary steaming , and then dried with anhydrous magnesium sulfate, let it stand overnight, and then filtered it with suction. The solution was distilled under reduced pressure at 110°C to obtain a crude product, which was furfuryl glycidyl ether FGE.

[0056] S3. Take another 112.08g of furfurylamine, add it to a ne...

Embodiment 3

[0063] This embodiment provides a method for preparing self-repairing cross-linked polyurethane, comprising the following steps:

[0064] S1. Mix 92.52g of epichlorohydrin and 98.1g of furfuryl alcohol, add the catalyst tetrabutylammonium bromide, put it into a 500ml three-neck flask, place it in an ice-water bath at 0°C for 4 hours, and obtain a mixed solution.

[0065] S2. Add 160ml of sodium hydroxide solution with a mass fraction of 50% dropwise to the mixed solution obtained in step S1, then place it in an ice-water bath for 1.5h, extract it three times with anhydrous ether, wash it with water three times, and dilute the ether by rotary steaming Recover, dry with anhydrous magnesium sulfate, let it stand overnight, and then carry out suction filtration, take the solution at 110°C, and distill under reduced pressure to obtain the crude product, which is furfuryl glycidyl ether FGE.

[0066] S3. Take another 112.08g of furfurylamine, add it to a new three-necked flask, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com